Heat treatment method of alloy steel 40Cr sample

A heat treatment method and alloy steel technology, applied in the field of heat treatment, can solve the problems of unqualified mechanical properties and increase production costs, and achieve the effects of reducing scrap rate and production cost, and improving elongation and section shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Heat the sample according to the following steps:

[0020] A. Quenching treatment: Process the alloy steel 40Cr into a sample blank with a diameter of 25mm, put it into a muffle furnace and heat it to 900°C for quenching, put 4 pieces each time, keep it warm for 130-150min, and cool it with a cooling medium for 10min. The cooling medium is a mixture of quenching liquid and water, and the volume ratio of quenching liquid and water is 1:10, and the quenching liquid is 2#PAG quenching liquid;

[0021] B. Tempering treatment: Then heat the sample blank to 470°C for tempering, keep it warm for 80 minutes, use a cooling medium to cool it to 70-80°C, then take it out and naturally cool it to room temperature. The cooling medium is a mixture of sesame oil and vegetable oil, and The volume ratio of sesame oil to vegetable oil is 4:1.

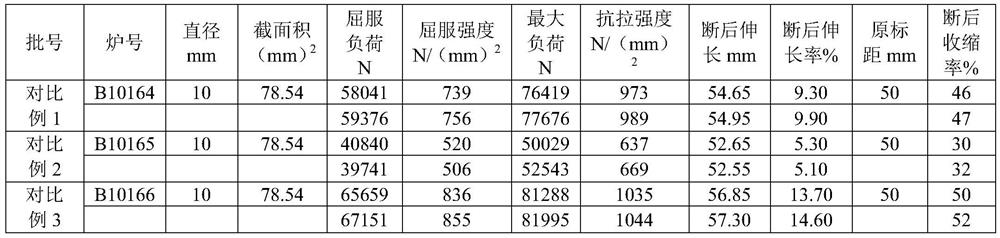

[0022] The mechanical properties of the 7 batches of sample blanks after the above heat treatment were tested:

[0023] Process the sample blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com