A kind of aluminum alloy material used for mobile phone structural parts and preparation method thereof

A technology of aluminum alloy material and mobile phone structure, which is applied in the field of aluminum alloy processing, can solve the problems of poor high-gloss mirror effect, low strength, and poor effect of surface decoration materials, etc., and achieve good surface treatment adaptability, improved alloy strength, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

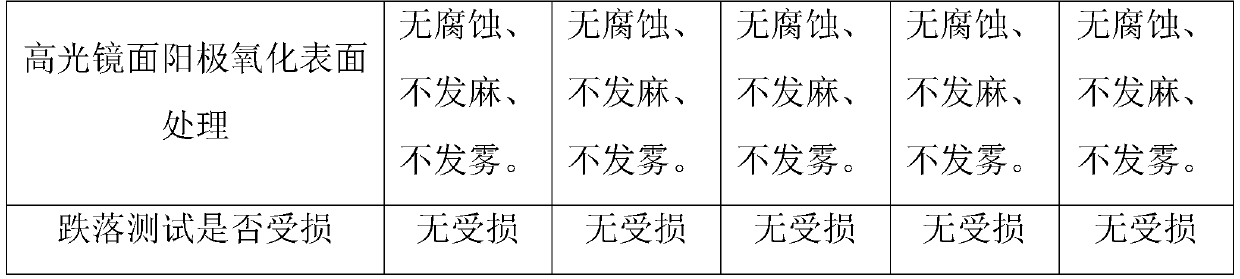

Examples

Embodiment 1

[0037] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.80%, Si 0.52%, Cu 0.52%, Mn 0.12%, Zr 0.05%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0038] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0039] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0040] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0041] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0042] D. Casting: semi-continuous water-cooled casting is carried out o...

Embodiment 2

[0054] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.84%, Si 0.56%, Cu 0.56%, Mn 0.16%, Zr 0.08%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0055] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0056] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0057] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0058] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0059] D. Casting: semi-continuous water-cooled casting is carried out o...

Embodiment 3

[0071] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.87%, Si 0.59%, Cu 0.59%, Mn 0.20%, Zr 0.11%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0072] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0073] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0074] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0075] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0076] D. Casting: semi-continuous water-cooled casting is carried out o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com