Cable-stayed bridge tower column concrete distributing device

A technology for material distribution devices and cable-stayed bridge towers, which can be used in bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as weak adaptability, single device structure, and inability to strengthen the shaking of residues in the feed pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

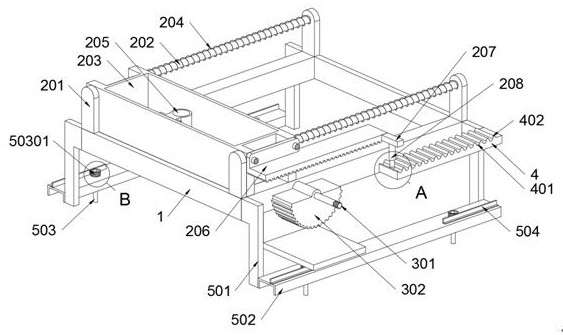

[0033] as attached figure 1 To attach Figure 7 Shown:

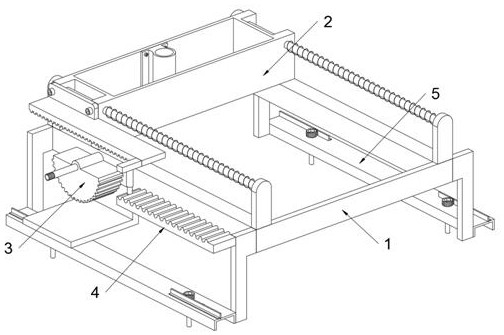

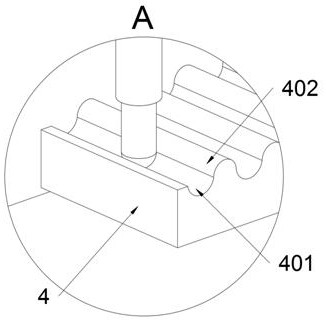

[0034] The invention provides a concrete distribution device for a cable-stayed bridge tower column, which includes a frame body 1; a sliding structure 2 is installed on the frame body 1, and a driving structure 3 is engaged with the sliding structure 2 for transmission; the frame body 1 is fixedly connected with a vibration plate 4, and two fixed structures 5 are symmetrically welded on the frame body 1; refer to Figure 4, the fixing structure 5 includes a fixing bolt 503, the fixing bolt 503 is plugged into the fixing hole on the fixing base 502, and the fixing bolt 503 is in contact with the baffle 504; the baffle 504 is an L-shaped structure, and the baffle 504 forms the fixing bolt The auxiliary locking structure of 503, so that when the fixing bolt 503 is tightened, the fixing seat 502 will bend and at this time the baffle plate 504 is in elastic contact with the fixing bolt 503, so that the elastic anti-looseni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com