Light fire-resistant roof structure

A fire-resistant and light-weight technology, applied in the direction of roofing, roof covering, roofing with flat/curved panels, etc., can solve the problems of fire-resistant protection failure and pollution, glass wool easily damped, poor durability, etc., to achieve simple construction and meet fire protection requirements. Requirements, the effect of achieving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in combination with specific embodiments.

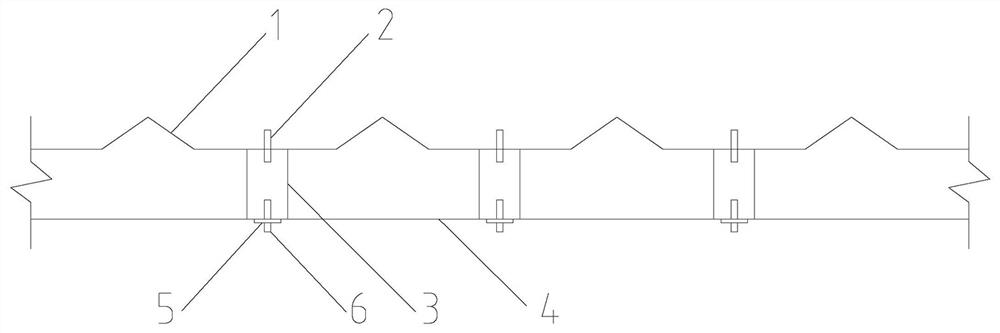

[0020] The invention relates to a light-weight fire-resistant roof structure. The structure includes a roof panel 1, purlins 3, fireproof cloth 4 and aluminum alloy battens 5; The cloth 4 is fixed to the purlin 3 through the aluminum alloy bead 5 . The roof panel 1 is a metal profiled plate.

[0021] Roof panels 1 and purlins 3 are connected by inner metal self-tapping screws 2 . The inner metal self-tapping screws 2 are evenly arranged along the purlin 3 direction.

[0022] The purlins 3 are galvanized square steel pipes arranged longitudinally and parallelly under the roof panel 1 . The aluminum alloy bead 5 is an aluminum alloy bead, and its position and direction correspond to the purlin 3 .

[0023] The aluminum alloy bead 5 fixes the fireproof cloth 4 to the purlin 3 through the outer metal self-tapping screws 6 . The outer metal self-tapping screws 6 are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com