Nylon insulated voltage transformer

A technology of voltage transformers and transformers, applied in the direction of inductors, transformers/inductor shells, transformers, etc., can solve problems such as endangering human health, polluting the environment, and refractory degradation, and achieves easy processing, good insulation performance, and solves hazards Effects on sex and pollution issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

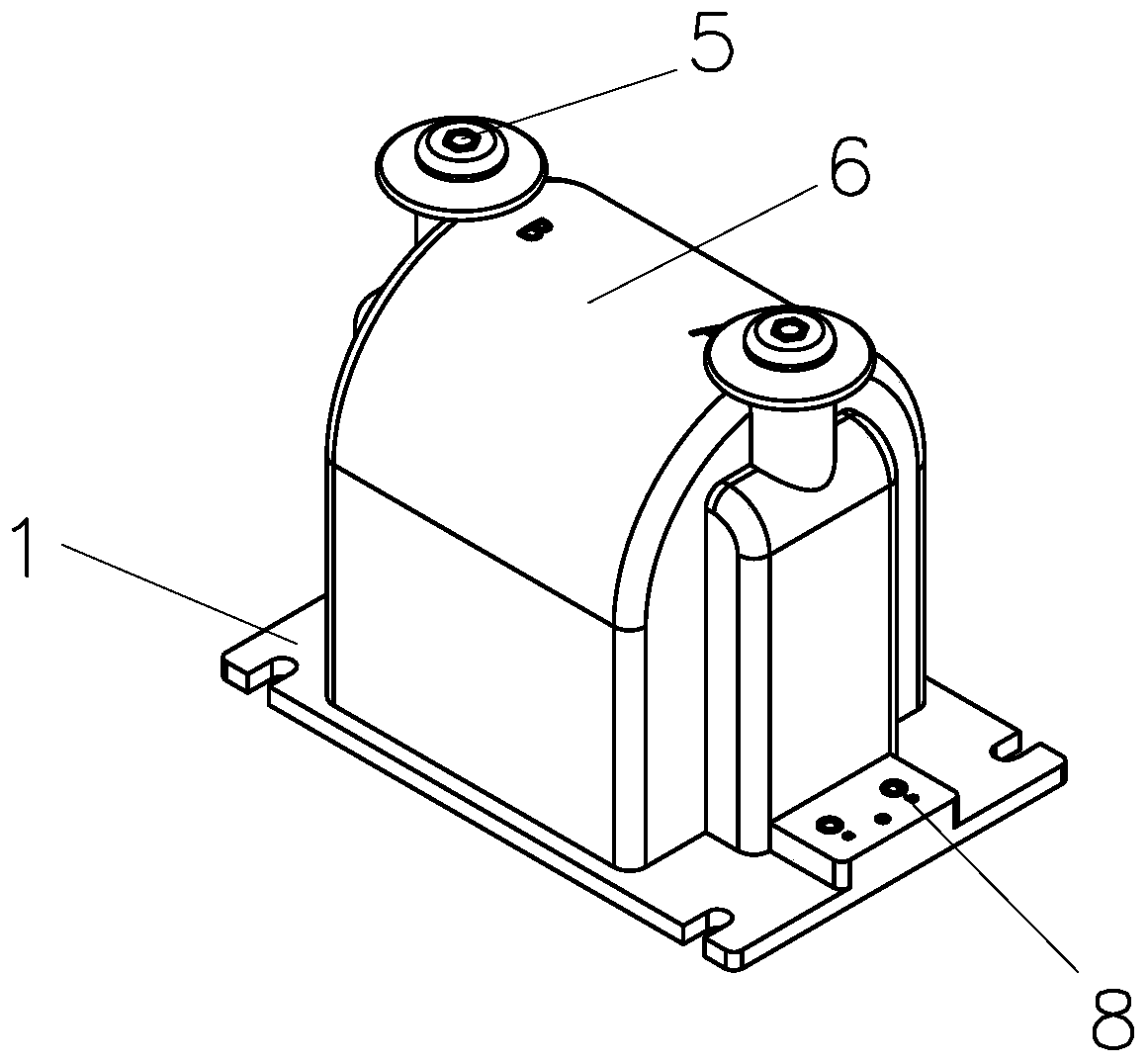

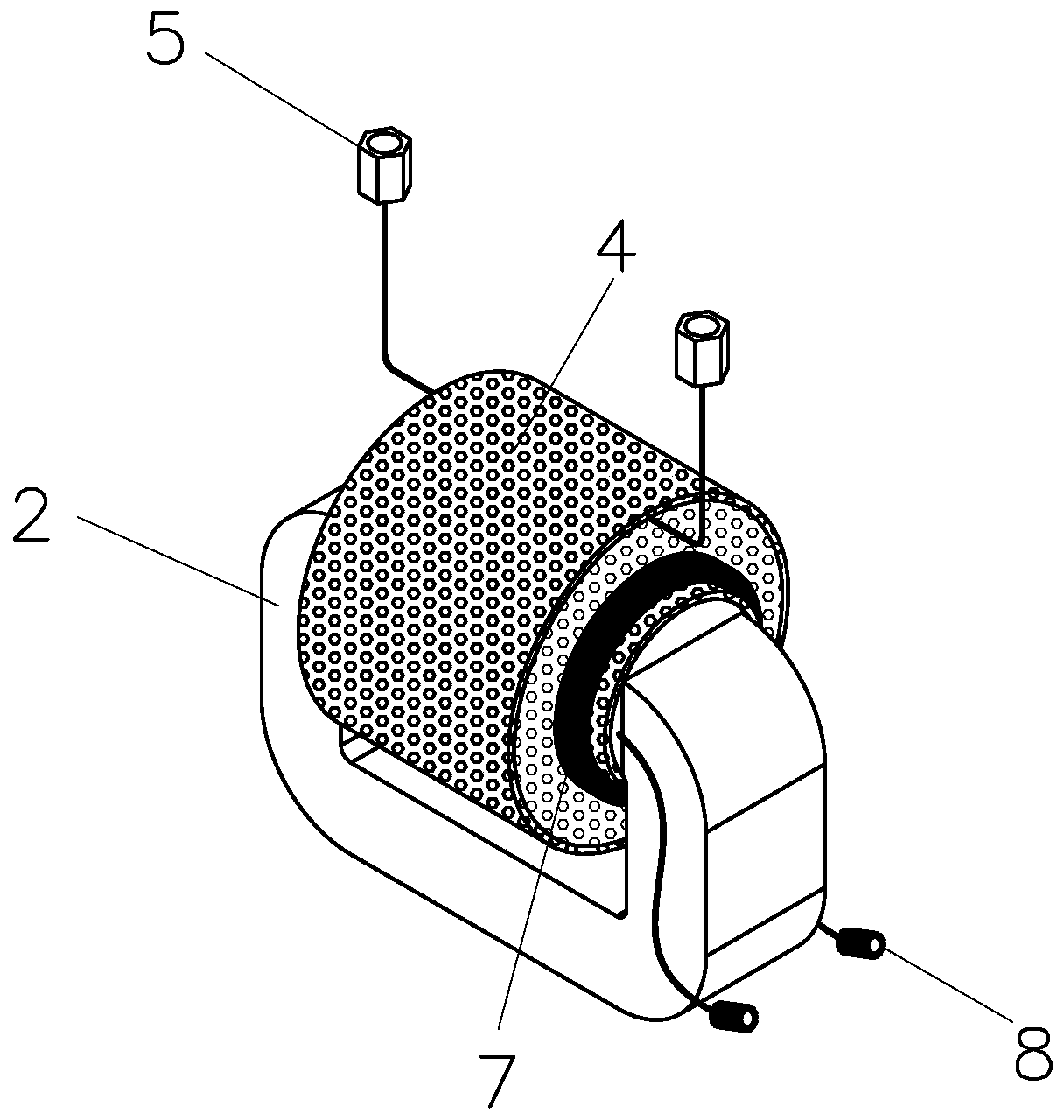

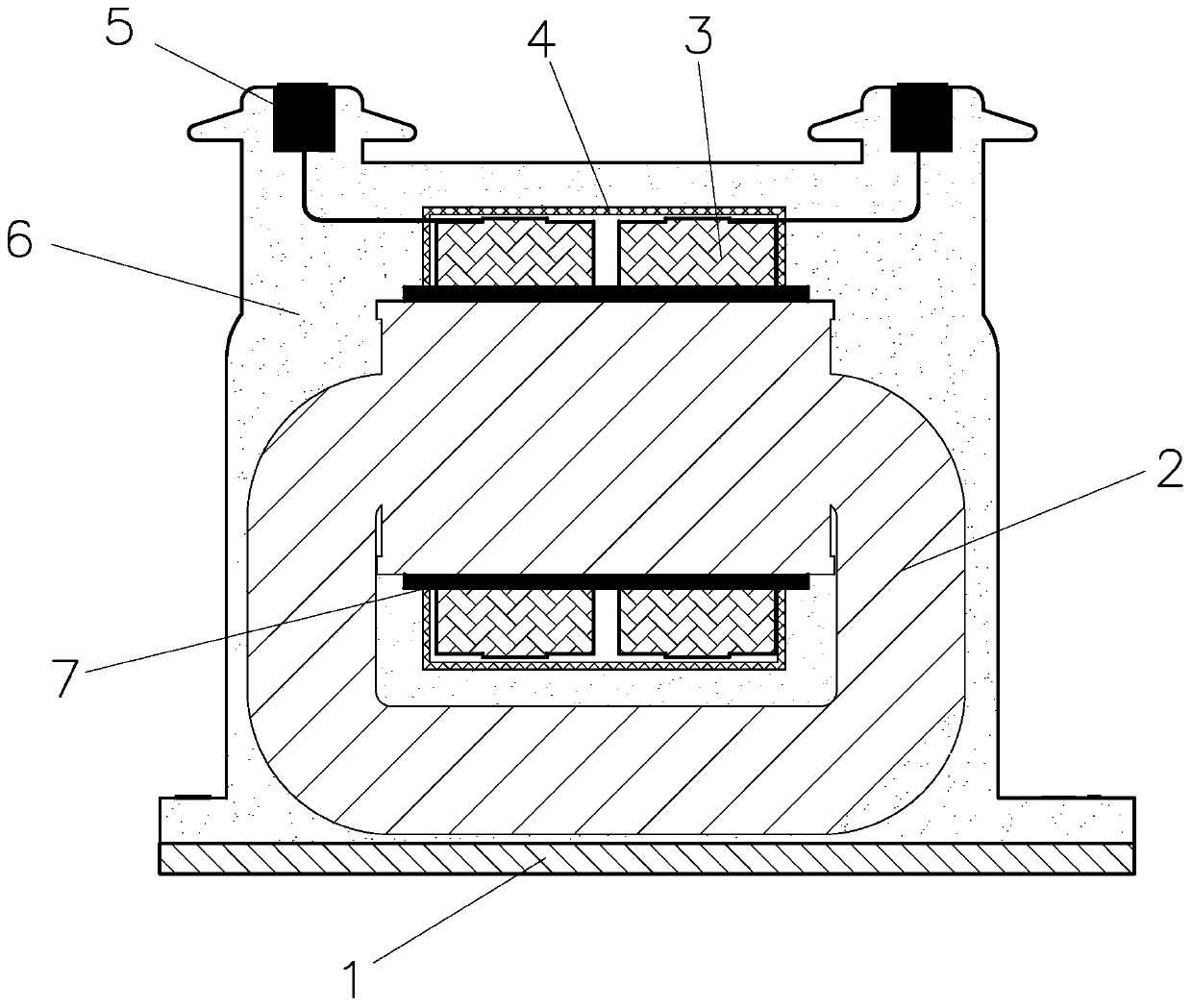

[0013] refer to Figure 1 to Figure 3 A nylon-insulated voltage transformer, including a bottom plate 1 for fixing the transformer, a ring-shaped iron core 2 on the bottom plate 1, a voltage transformer coil 3 wound on the ring-shaped iron core 2, and a voltage transformer coil 3 is electrically connected to the primary terminal 5, the outer sealing sleeve of the voltage transformer coil 3 is provided with a heat insulating layer 4, and the outer part of the transformer is formed by injection molding nylon to form a nylon inclusion 6. The annular iron core 2, the voltage transformer coil 3 and the The transformer line is wrapped to realize insulation, and the primary electric terminal exposes the surface of the nylon inclusion 6 . Nylon material has the advantages of good insulation performance, easy processing and not easily deformed by heat and force. It can effectively replace epoxy resin to insulate and isolate the internal components of voltage transformers, and solve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com