Efficient ground tiling joint filling device for constructional engineering

A construction engineering and ground technology, applied in the direction of construction and building structure, can solve the problems of deviation of filling trajectory, reduce the efficiency of filling gap, and low friction, so as to reduce the possibility of shaking, improve the degree of automation, and improve the extrusion. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

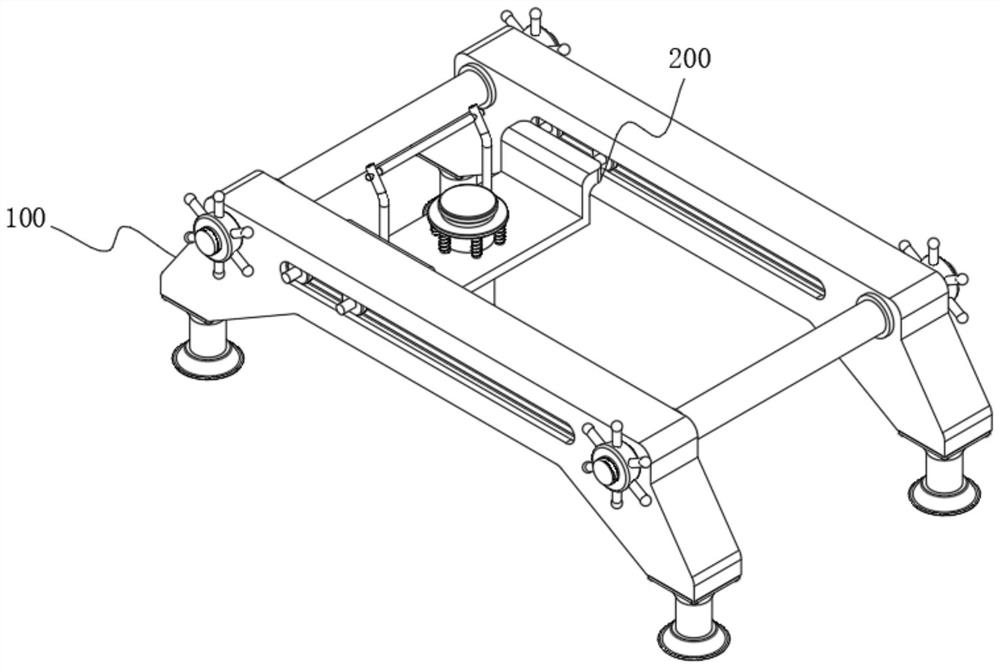

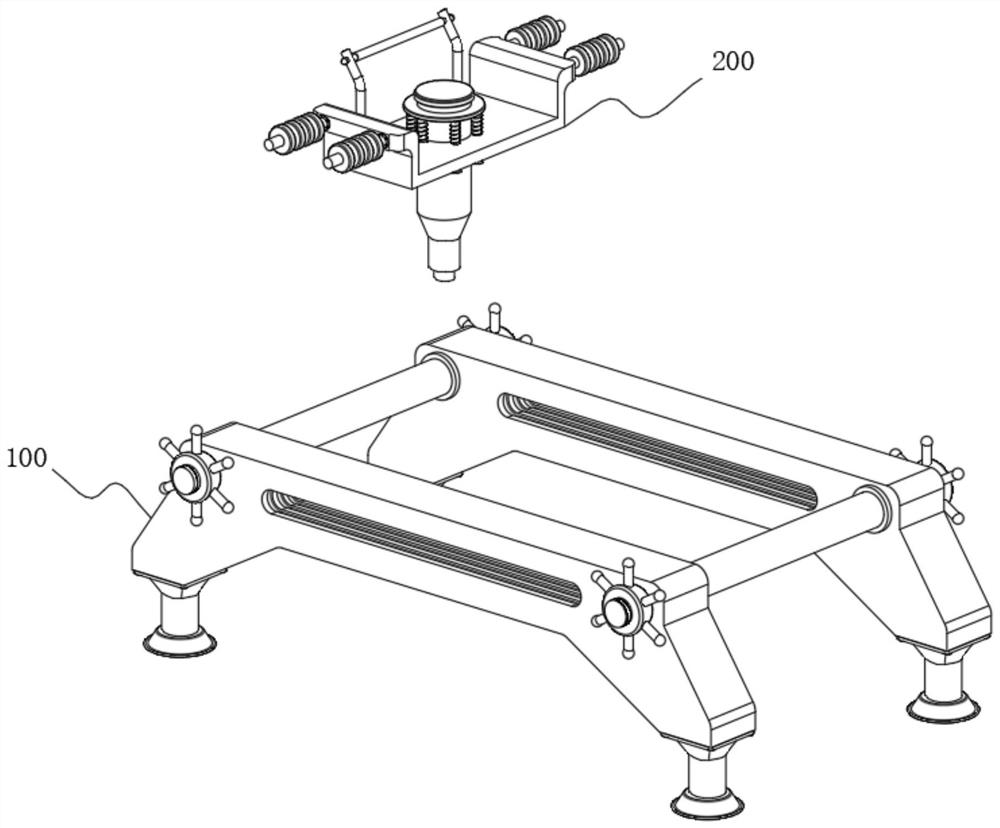

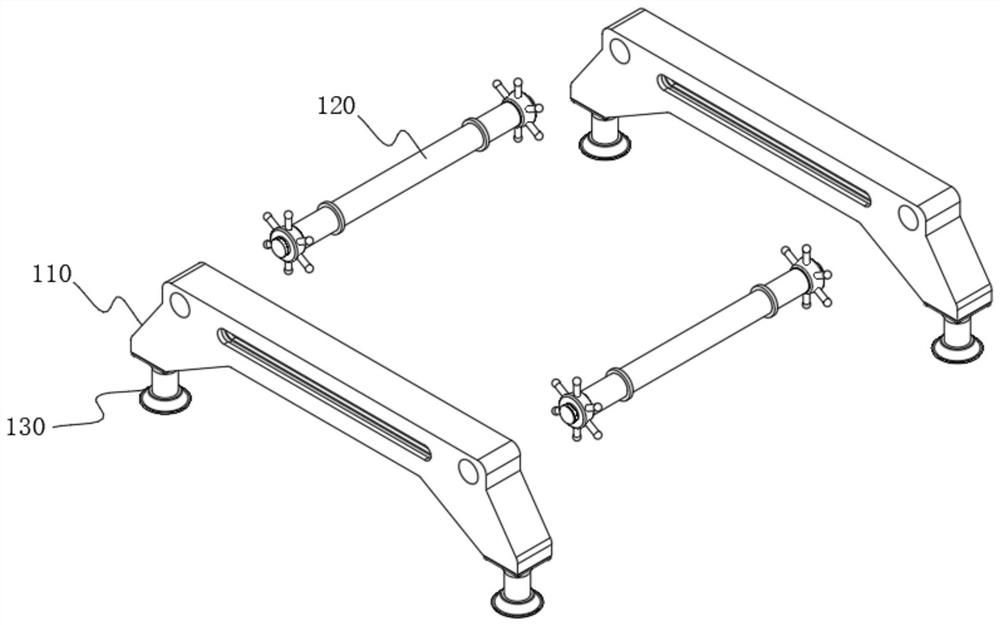

[0055] see Figure 1-Figure 11 As shown, the purpose of this embodiment is to provide a high-efficiency joint filling device for floor tiles for construction engineering, including a position limiting guide mechanism 100 and a joint filling mechanism 200 arranged inside the position limit guide mechanism 100, which is characterized in that: Position guide mechanism 100 comprises two guide frames 110, is provided with connecting shaft 120 symmetrically between two guide frames 110, and connecting shaft 120 is fixedly connected with guide frame 110, and the bottom of guide frame 110 is symmetrically provided with limit device 130, and limit device 130 includes a limit suction cup 131 , and the top of the limit suction cup 131 is provided with a column 132 for fixed connection with the guide frame 110 .

[0056]In this embodiment, when the limit suction cup 131 is in specific use, first move the guide frame 110, place the limit suction cup 131 at the bottom of the guide frame 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com