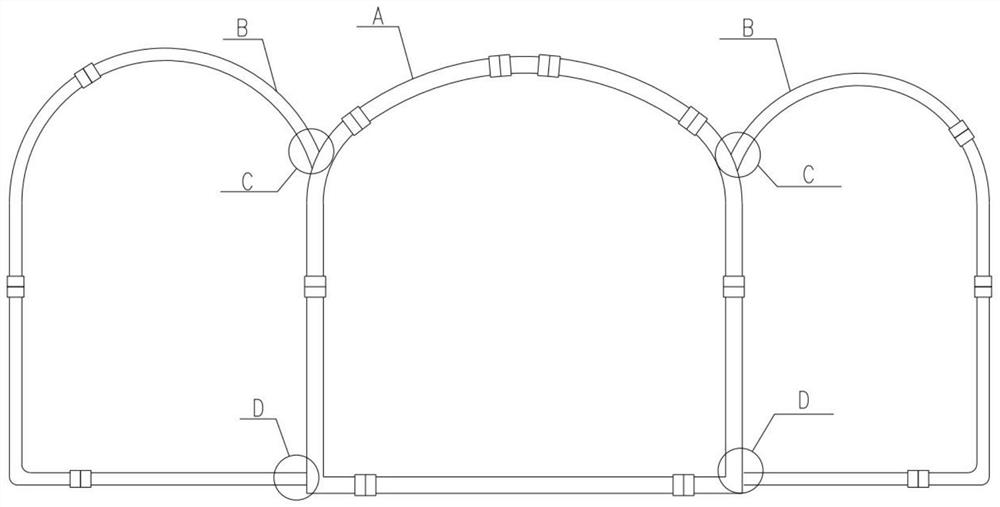

Steel bar grating connecting structure for multi-arch underground excavation pipe gallery primary support structure and construction method

A technology for connecting structures and steel grids, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as difficulties in the construction and handling of steel grids, and achieve the effects of saving construction time, improving construction progress, and reducing impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

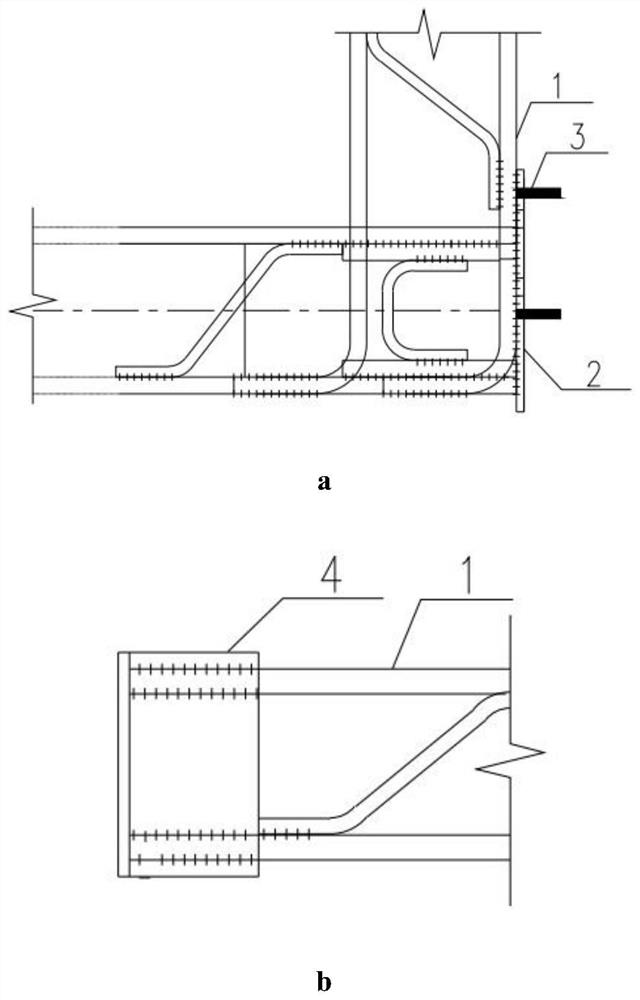

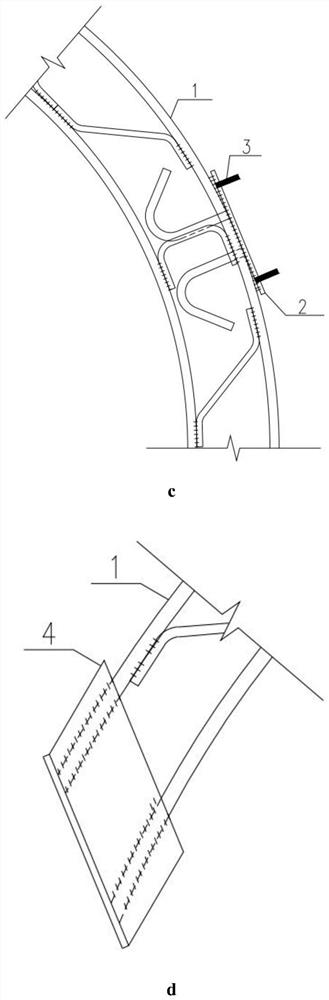

[0026] according to Figure 1 - Figure 5 When using, when the inter-arch mounted positive distribution is constructed, the steel plate 2 is disposed at the first-opening reinforcing reinforced grid main ratio and the adjacent bun, and the steel plate 2 has four reserved holes. The four high-strength bolts 3 is welded to the reserved hole by the plug welding process, and the steel plate 2 is connected firmly to complete the installation of the reinforcement grille; subsequent excavation of the neighboring bin to the co-constructed connection position, in the subsequent excavation of the neighbor The reinforcing grille main ratio 1 is connected to the end head welding firmly two corner steel 4, and four bolt reserved holes 5 are provided on the angle steel 2, and the other end of the four high-strength bolts 3 passes through the bolt reserved hole 5 on the angle steel 4, The nut 6 is tightened, so that the first line opens the bin and subsequent excavation of the neighboring reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com