Operation control method and device of discharging motor, cooking utensil and storage medium

A technology for operation control and feeding motors, applied in the fields of cooking utensils and computer-readable storage media, can solve the problems of bacteria breeding, deterioration, and impact on user's food hygiene in stored materials, so as to reduce production costs, reduce hidden dangers of electrical appliances, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

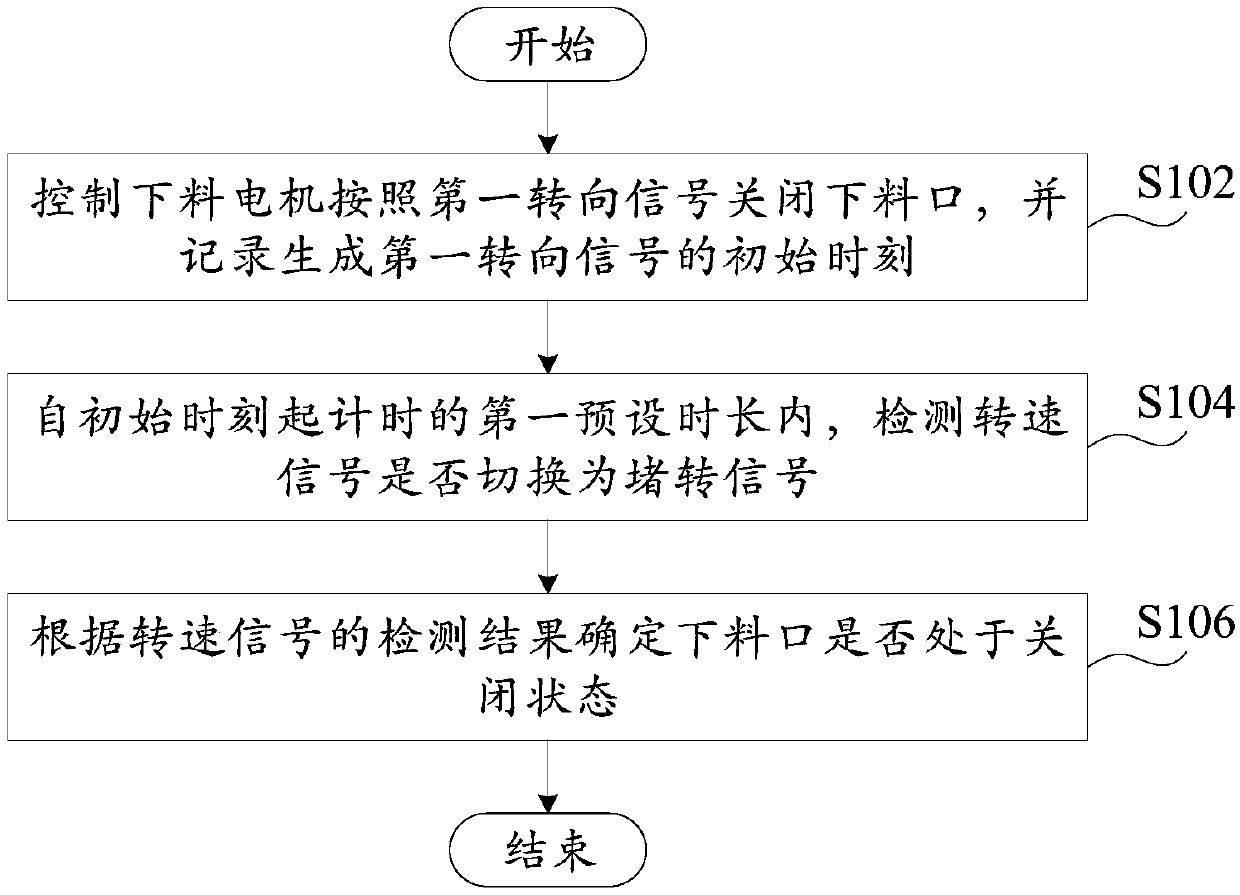

[0055] figure 1 A schematic flowchart of the operation control method of the feeding motor according to Embodiment 1 of the present invention is shown.

[0056] like figure 1 As shown, the operation control method of the blanking motor according to Embodiment 1 of the present invention includes: step S102, controlling the blanking motor to close the blanking port according to the first steering signal, and recording the initial moment when the first steering signal is generated; step S104, within the first preset time period counted from the initial moment, detect whether the rotation speed signal of the feeding motor is switched to a stall signal; step S106, determine whether the feeding port is closed according to the detection result of the rotation speed signal.

[0057] In this technical solution, within the first preset time period counted from the initial moment, it is detected whether the speed signal of the feeding motor is switched to a stall signal, and it is deter...

Embodiment 2

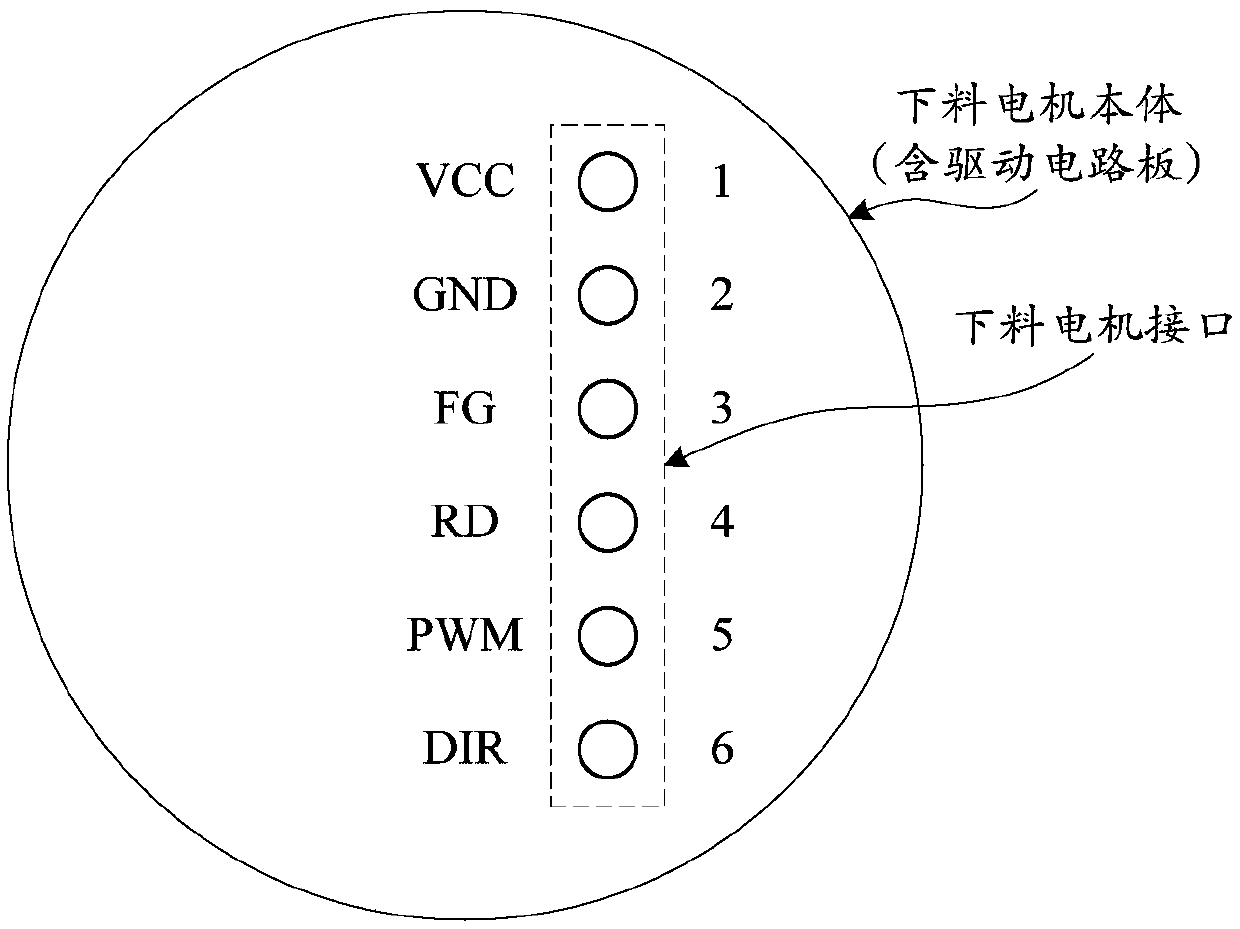

[0073] figure 2 A schematic diagram of the circuit interface of the feeding motor according to the second embodiment of the present invention is shown.

[0074] like figure 2 As shown, the circuit interface of the blanking motor according to Embodiment 2 of the present invention includes:

[0075] (1) VCC, GND: respectively power supply and ground, which are output by the control system to provide power to the feeding motor. Among them, the control system is logic control devices such as MCU, DSP, CPU and embedded equipment.

[0076] (2) FG: It is the first feedback interface of the feeding motor, which is used to output the load signal to the control system to detect the speed of the feeding motor. The number of FG pulses per unit time is different for different speeds of the feeding motor. The number of pulses is obtained from experiments. When the feeding motor is running, the FG pin outputs pulses continuously.

[0077] (3) RD: It is the second feedback interface of t...

Embodiment 3

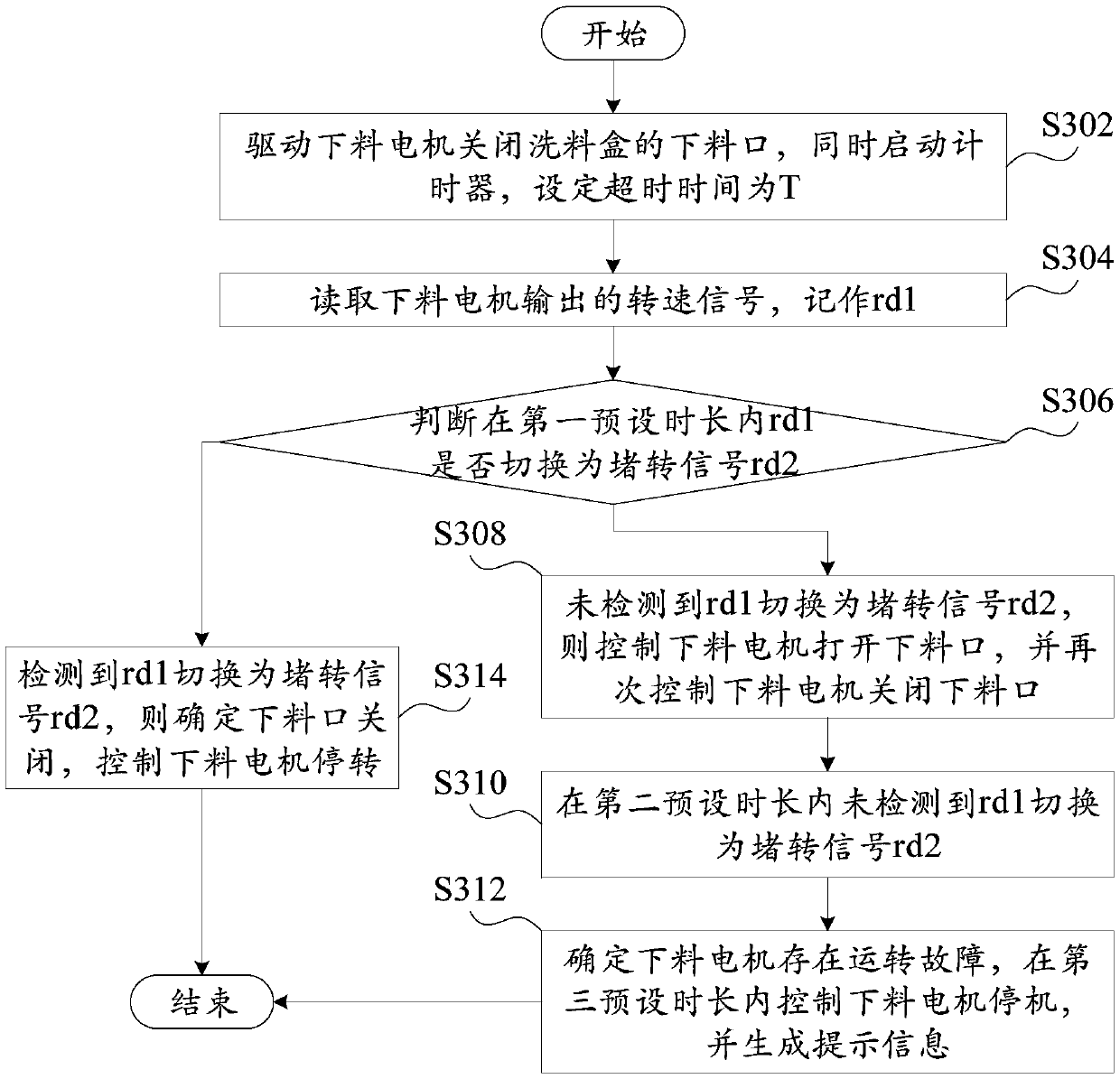

[0082] image 3 A schematic flowchart of the operation control method of the feeding motor according to the third embodiment of the present invention is shown.

[0083] like image 3 As shown, the operation control method of the unloading motor according to the third embodiment of the present invention includes: step S302, driving the unloading motor to close the unloading port of the washing box, and starting the timer at the same time, setting the timeout time as T; S304, read the rotation speed signal output by the feeding motor, and record it as rd1; step S306, judge whether rd1 is switched to the stall signal rd2 within the first preset time length; step S308, switch from rd1 to the stall signal rd2 if it is not detected, Then control the feeding motor to open the feeding port, and control the feeding motor to close the feeding port again; Step S310, it is not detected within the second preset time length that rd1 is switched to a stall signal rd2; Step S312, it is deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com