Friction constant-resistance grading yielding anchor rod

A technology of giving way to bolts and bolts, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of cumbersome installation, non-reversibility, and different deformation states, so as to achieve convenient installation and improve anchorage. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

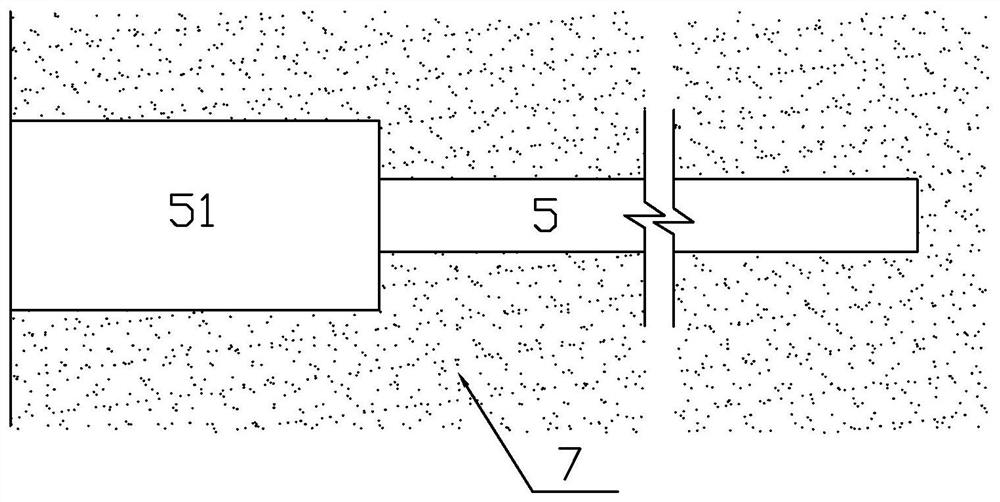

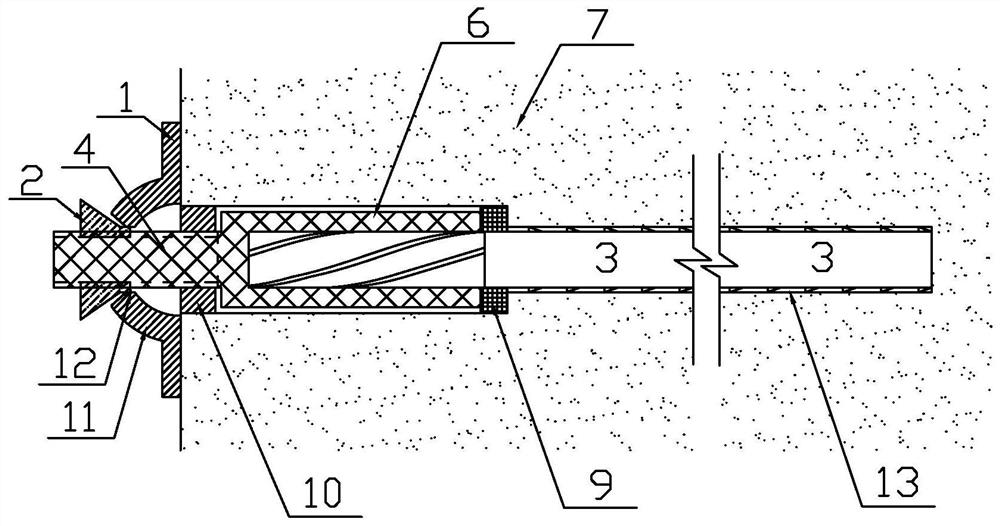

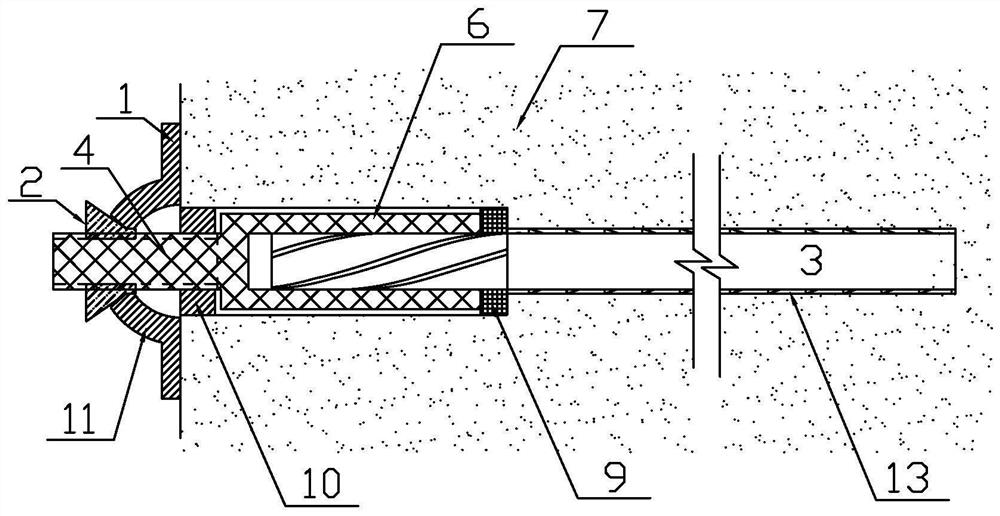

[0025] Implementation mode one: if Figure 1-4 As shown, the frictional constant resistance graded pressure anchor includes an arched support body 1, a fastening nut 2, an anchor body 3 and a screw rod 4, the screw rod 4 is exposed outside the matching anchor hole 5, and the arched support body 1 is made of steel plate, the center of which bulges outward to form a bulge 11, and the center of the bulge 11 has a through hole 12, and is sleeved on the screw 4 through the through hole 12,

[0026] The fastening nut 2 is screwed on the screw rod 4, the fastening nut 2 is threadedly matched with the screw rod 4, the threads of the fastening nut 2 and the screw rod 4 are self-locking threads, and the fastening nut 2 is pressed on the raised portion 11, which is characterized in that it also includes a rotating cylinder 6, one end of the screw 4 is directly coaxially fixed with the outer end of the rotating cylinder 6, and is integrally formed, and the outer end of the bolt body 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com