Thermoelectric unit thermoelectric decoupling system and operation method

A thermoelectric unit and thermoelectric technology, which is applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as low energy utilization efficiency and inability to meet power grid electricity requirements, and achieve improved heating efficiency and flexibility. to achieve the effect of thermo-electrolysis coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

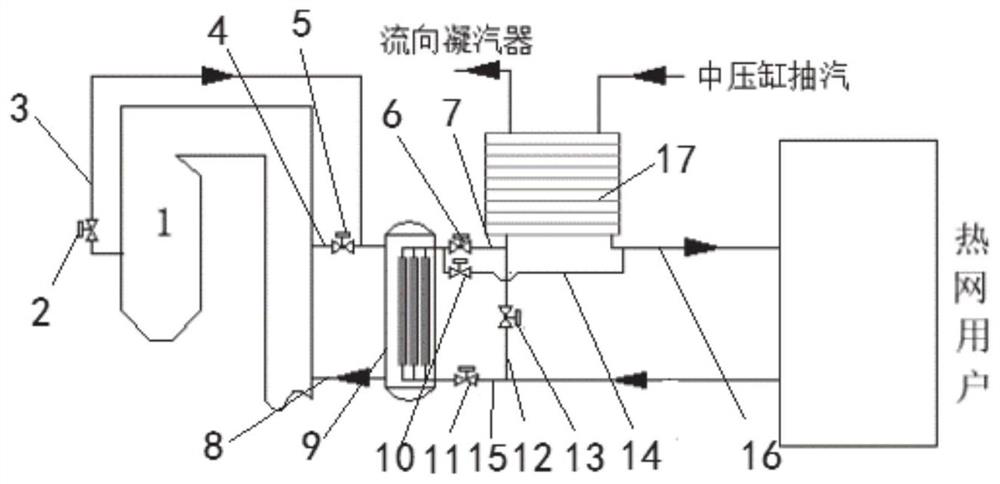

[0034] In this embodiment, a thermoelectric decoupling system of a thermoelectric unit is disclosed, with a structure such as figure 1 As shown, it includes a furnace 1, a heat exchange boiler 9 and a thermal station 17. The air inlet of the heat exchange boiler 1 communicates with the first pipe 3 and the second pipe 4 respectively, and the first pipe 3 communicates with the high-temperature flue gas outlet of the furnace 1. The second pipeline 4 communicates with the low-temperature flue gas outlet of the furnace 1, and the high-temperature flue gas and low-temperature flue gas of the furnace 1 are mixed into medium-temperature flue gas and then enter the heat exchange boiler 9 to release heat, which is the heat exchange boiler 9 The water is heated, and the high-temperature flue gas outlet baffle 2 is set on the first pipe 3, and the low-temperature flue gas outlet baffle 5 is set on the second pipe 4. By adjusting the high-temperature flue gas outlet baffle 2 and the low-te...

Embodiment 2

[0050] In this embodiment, a method for operating a thermoelectric decoupling system of a thermoelectric unit is proposed, including:

[0051] When the heating and power supply are all satisfied, the seventh valve is opened, the third valve, the fourth valve, and the sixth valve are closed, and the high-temperature water required by the heating network users is completely provided by the thermal station, and the low-temperature water discharged by the heating network users is re- Enter the thermal station to absorb heat.

[0052] In this case, in order to prevent the heat exchange boiler from being damaged due to dry burning, the high-temperature flue gas outlet baffle and the low-temperature flue gas outlet baffle are closed at the same time.

[0053] When the heat supply is satisfied and the power supply is not satisfied, the fourth valve and the sixth valve are opened, the third valve and the seventh valve are closed, and the high-temperature water of the heat exchange boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com