A device for measuring frictional torque of dynamic sealing contact surface

A technology of rotational torque and measuring device, which is applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problem that the contact bearing friction has a great influence, cannot meet the requirements of accurate measurement of friction and rotational torque of dynamic seal contact surface, and the stirring work of sealing medium Consumption of friction torque and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

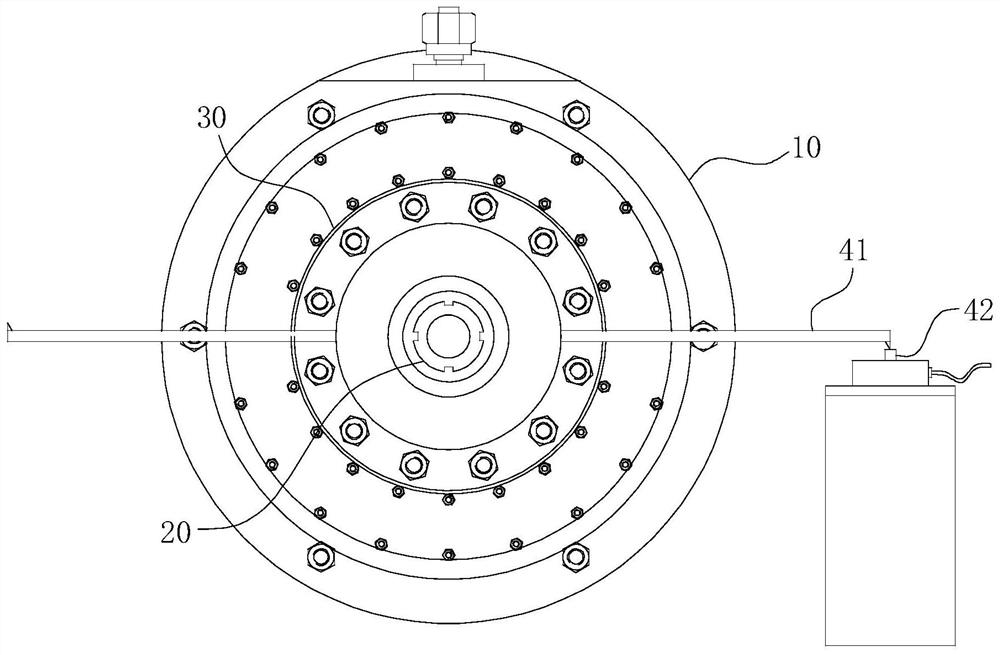

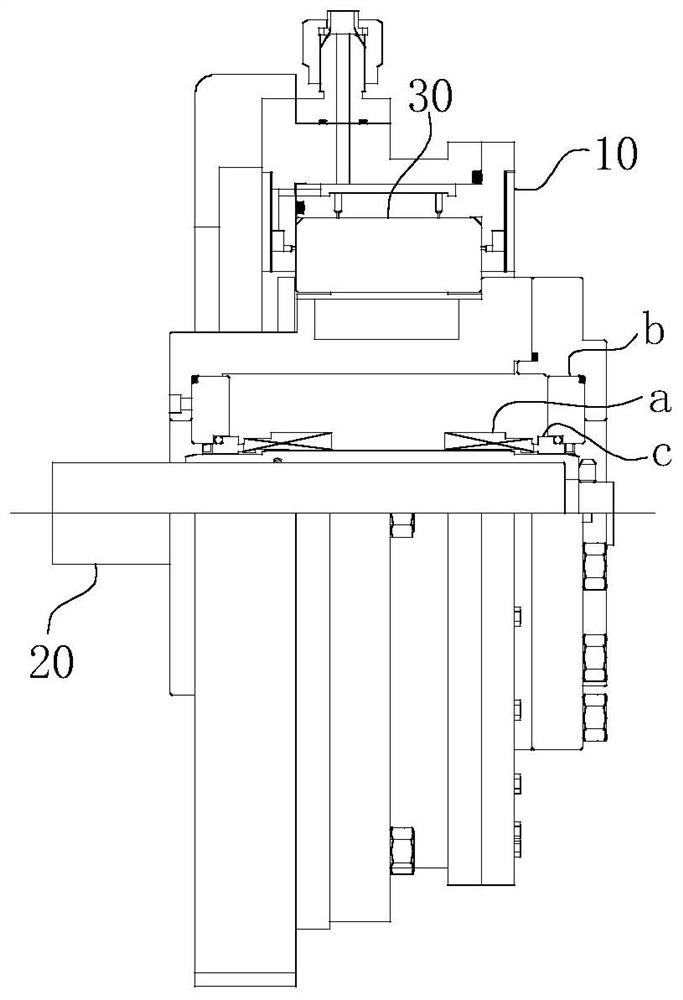

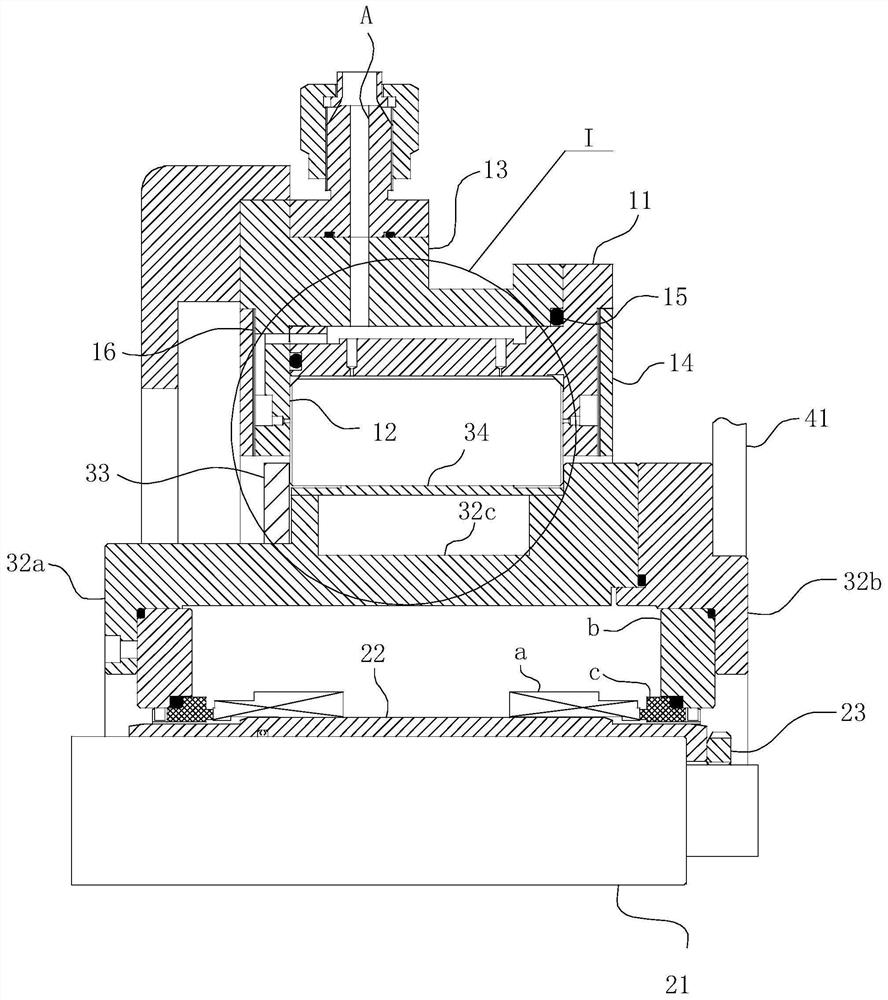

[0042] The floating measurement part 30 includes a hydrostatic bearing 31 as a core member. As shown in Figure 3-4, the gas static

[0043] For the static component 10, including a first gas static shell 11, a second gas static shell 13, a gland 12 and a cover 14. in Figure 3‑

[0049] 2), the present invention improves the reliability of the dynamic seal contact surface end face friction torque measurement. used in the present invention

[0050] 3), the present invention provides a universal measurement method for realizing the friction torque of the dynamic seal contact surface end face. Book

[0051] Of course, for those skilled in the art, the invention is not limited to the details of the above-described exemplary embodiments, and

[0052] Furthermore, it should be understood that although this specification is described in terms of embodiments, not every embodiment includes only

[0053] The technology, shape and structural part not described in detail in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com