Method for testing 110kV capacitive voltage transformer without disassembling lead

A voltage transformer without removing the lead wire technology, which is applied in the test field of 110kV capacitive voltage transformer without removing the lead wire. Intensity reduction, precisely measured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

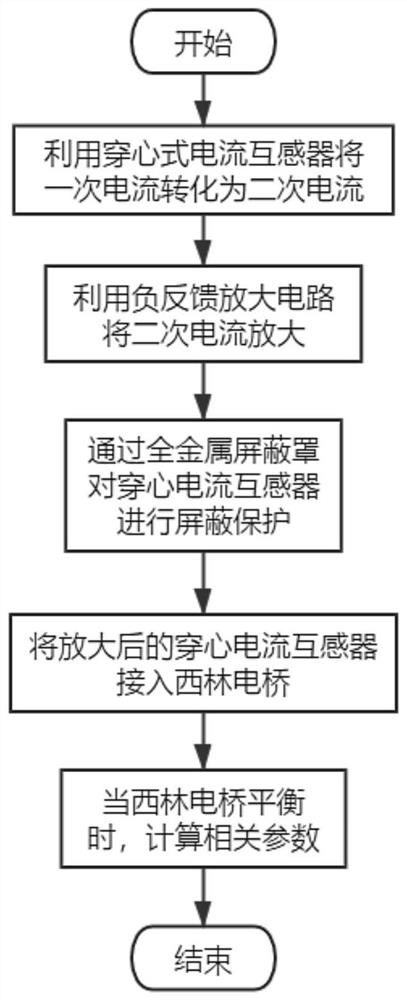

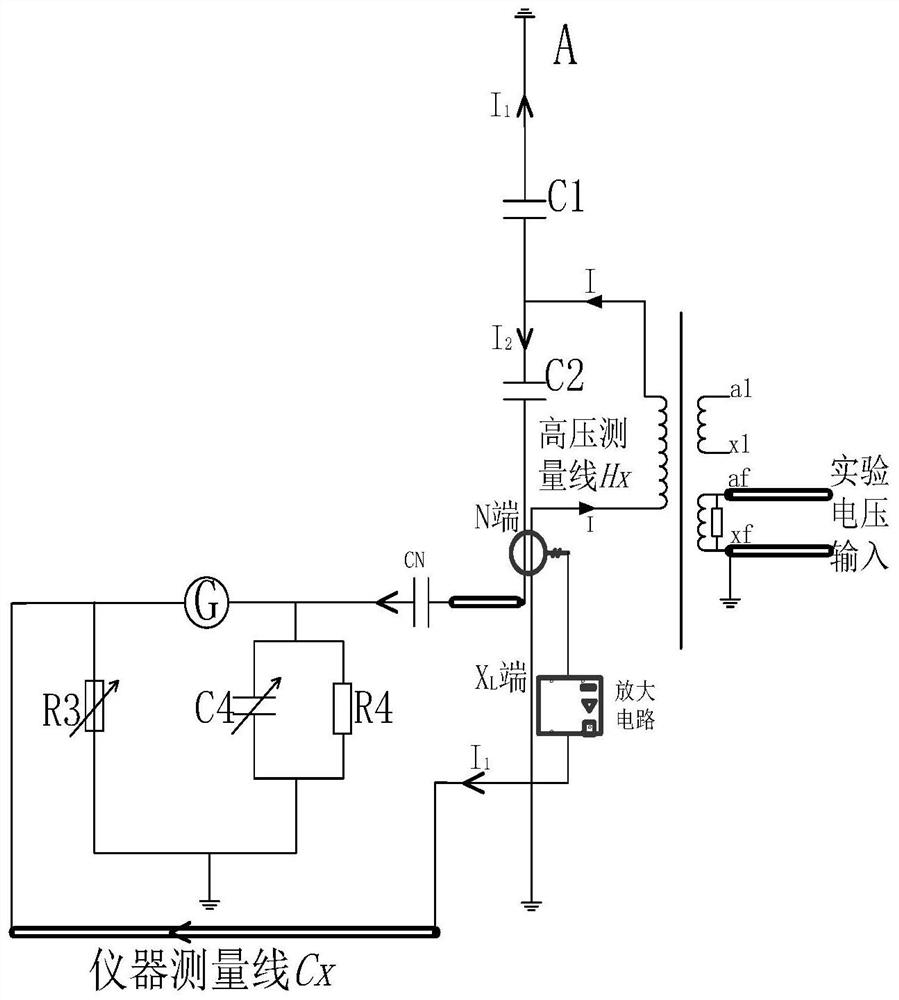

[0044] refer to Figure 1 ~ Figure 3, is the first embodiment of the present invention, this embodiment provides 110kV capacitive voltage transformer test method without removing the lead wires, including:

[0045] S1: The test current flowing through the primary lead wire is converted into a secondary current through a feed-through current transformer.

[0046] Change the feed-through current transformer from the top of the primary lead to the low-voltage secondary terminal. The primary lead of the feed-through current transformer is connected to the XL terminal current and the reverse N terminal current, and the subtraction of the two is to flow once. Current at the leads:

[0047] I C1 =I XL -I C2

[0048] Among them, I C1 is the test current of the primary lead, I C2 Connect the reverse N-terminal current to the primary lead wire of the feed-through current transformer, I XL It is the current connected to the XL terminal for the primary lead wire of the feedthrough...

Embodiment 2

[0073] In order to verify and explain the technical effect adopted in this method, this embodiment chooses the traditional method of removing the lead wire and adopts this method to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0074] The traditional lead wire removal method: the work intensity of removing and restoring the lead wire is high, the lead wire connection of the primary lead wire is relatively firm, and the staff needs to climb up to operate; it takes a long time to remove the lead wire and restore the lead wire during the whole test process; the personal risk factor is high, and a large number of high-altitude operations For example, there is a greater risk of personnel falling; there are certain hidden dangers of equipment, because the high-voltage lead wires are corroded during the operation of outdoor equipment, so when the lead wires are restored, the lead wires may not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com