Carbon fiber thin-wall cylinder type main supporting structure of large-aperture space camera

A space camera and thin-walled cylinder technology, applied in the field of space optical remote sensing, can solve problems such as difficulty in satisfying self-weight deformation and vibration response, low specific stiffness, and difficulty in controlling the size and weight of the whole machine, so as to reduce product quality and meet shading requirements , reducing the effect of the product envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

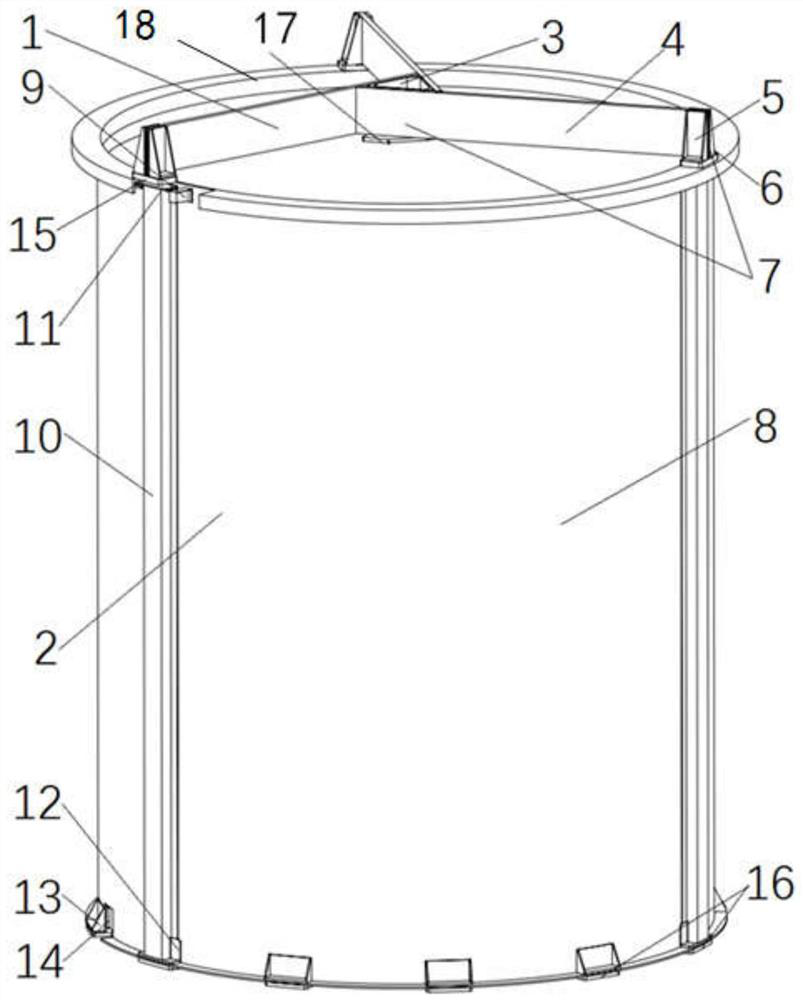

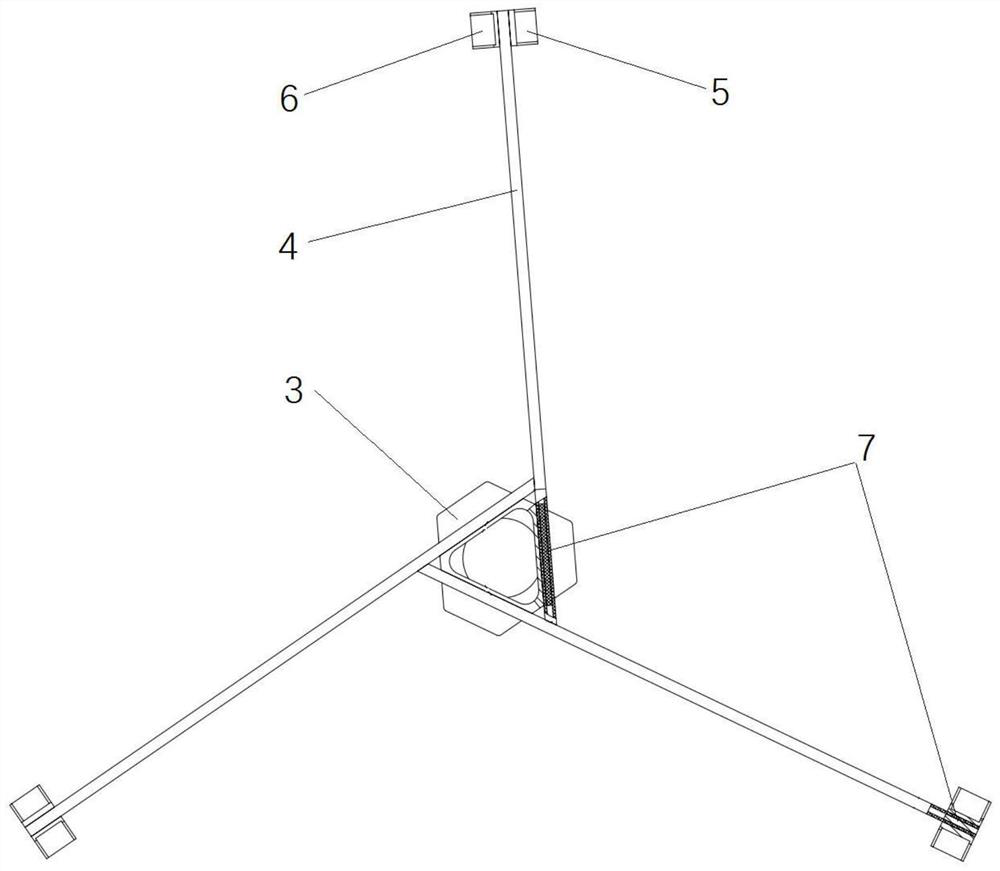

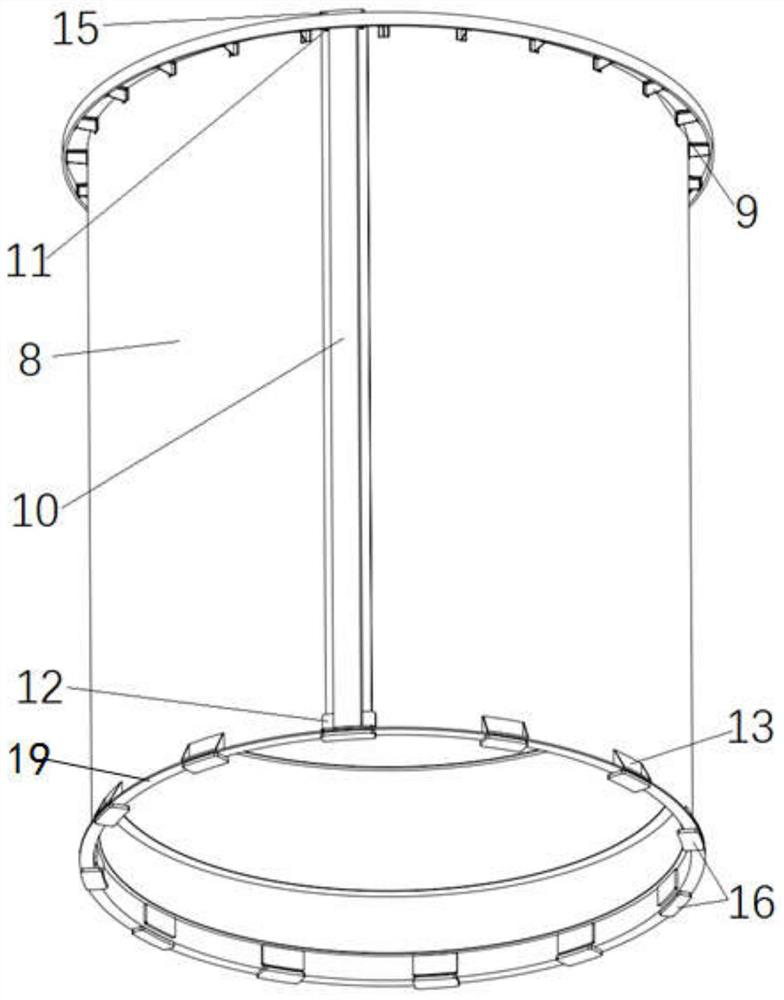

[0028] like Figure 1-Figure 3 As shown, a carbon fiber thin-walled cylindrical main support structure for a large-caliber space camera includes a secondary mirror truss assembly 1 and a front cylinder assembly 2, and the secondary mirror truss assembly 1 includes a secondary mirror joint 3, three secondary mirror truss rods 4, Several truss bar left clips 5 and some truss bar right clips 6 are provided with a secondary mirror assembly interface 17 on the lower surface of the secondary mirror joint 3, and three adhesive mounting surfaces are uniformly arranged on the side wall of the secondary mirror joint 3, and equipped with There are corresponding threaded holes for connecting with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com