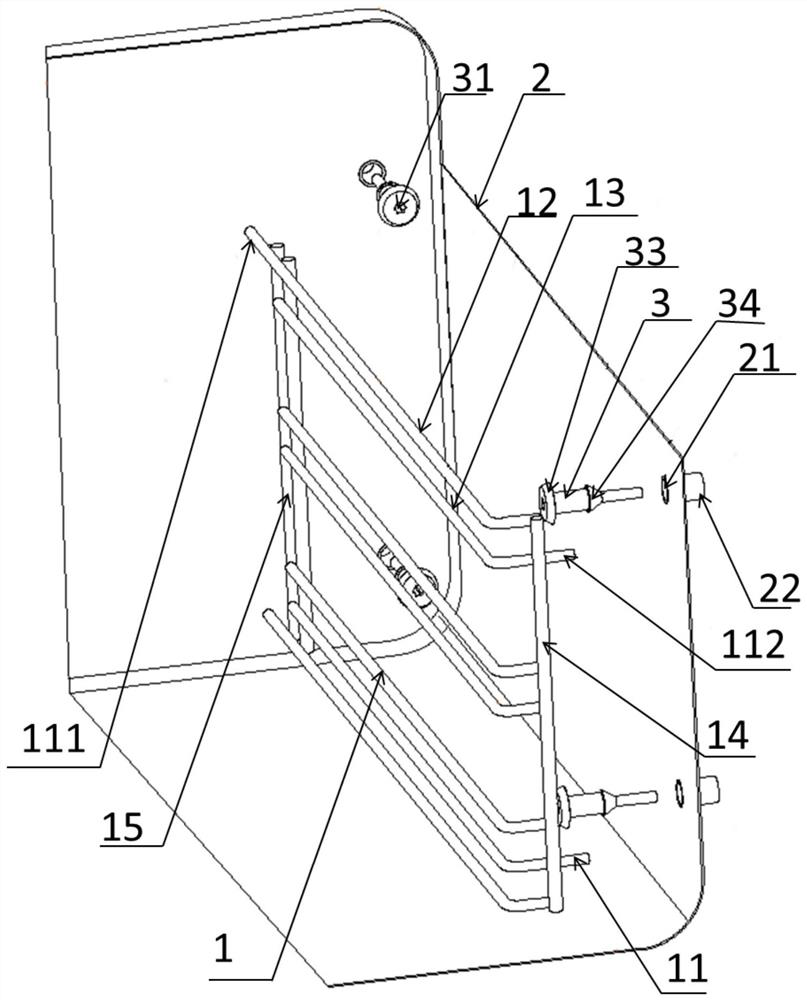

Steam oven hanger mounting structure

An installation structure and technology of a steaming oven, applied in the field of steaming ovens, can solve the problem of high cost of raw materials and processing costs, and achieve the effects of simple installation method, preventing hanging racks from falling off, and easy disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

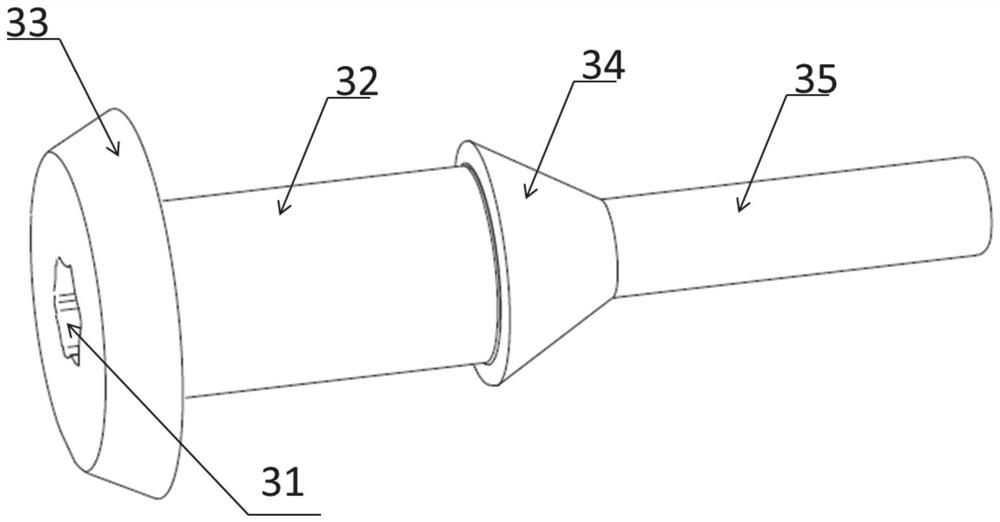

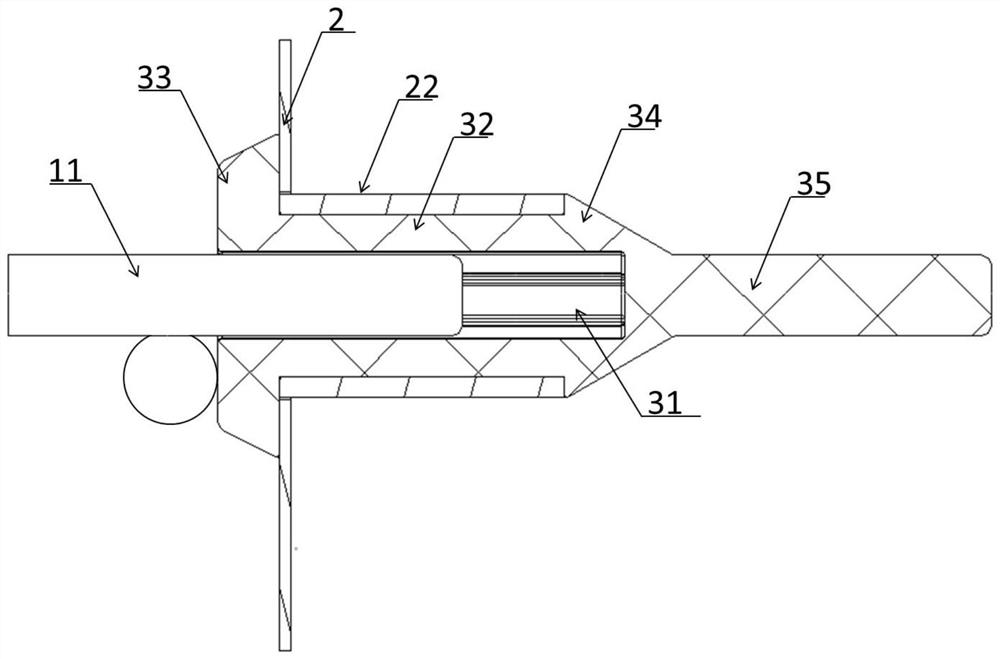

[0042] Such as image 3As shown, in the installation structure of a hanging rack of a steaming oven described in this embodiment, the fixing seat 3 is provided with a first limiting portion 33 that is stuck on the end of the sleeve 22 close to the inner tank side plate 2 . When installing the fixing base 3 , the fixing base 3 is inserted into the sleeve 22 , and one end of the fixing base 3 passes through the sleeve 22 . Since the first limiting portion 33 is provided on the fixed seat 3, and the outer diameter of the first limiting portion 33 is greater than the outer diameter of the sleeve 22, the first limiting portion 33 cannot pass through the sleeve 22, and the first limiting portion 33 cannot pass through the sleeve 22. The position part 33 is stuck on the inner tank side plate 2 to prevent the fixing seat 3 from moving to the inner side of the inner tank side plate 2 along the sleeve 22 .

[0043] At the same time, an insertion hole 31 is provided in the middle of the...

Embodiment 2

[0046] Such as image 3 As shown, in the installation structure of a rack for a steaming oven described in this embodiment, the fixing seat 3 includes a connecting portion 32 inserted into the sleeve 22 , and there is a socket 31 in the middle of the connecting portion 32 that matches the first limiting portion 33 After the fixing seat 3 is inserted into the sleeve 22 , the connecting portion 32 is located inside the sleeve 22 , and the plug 11 is inserted into the first limiting portion 33 and the connecting portion 32 through the socket 31 in sequence.

[0047] The outer diameter of the connecting portion 32 is larger than the inner diameter of the sleeve 22 , and when the fixing seat 3 is inserted into the sleeve 22 , the connecting portion 32 is pressed inwardly by the sleeve 22 . After the plug 11 is inserted into the socket 31 in the connecting part 32, the connecting part 32 is further compressed, and the elasticity of the rubber generates pressure between the connectin...

Embodiment 3

[0050] Such as image 3 As shown, in the hanging rack installation structure of a steaming oven described in this embodiment, the second limiting portion 34 is located at the end of the connecting portion 32 away from the side plate 2 of the inner tank, the surface of the second limiting portion 34 is an inclined plane, and the second limiting portion 34 is inclined. The outer diameter of the end of the positioning portion 34 close to the connecting portion 32 is larger than the outer diameter of the connecting portion 32 , and the outer diameter of the second limiting portion 34 away from the connecting portion 32 is smaller than the inner diameter of the sleeve 22 .

[0051] When the fixing seat 3 is inserted into the sleeve pipe 22, since the outer diameter of the second limiting portion 34 away from the end of the connecting portion 32 is smaller than the inner diameter of the sleeve pipe 22, the second limiting portion 34 can smoothly enter the sleeve pipe 22, which is con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap