Internal and external disturbance type mixing device and efficient stirring method

A stirring method and driving device technology, which are applied in mixers, chemical instruments and methods, mixers and other directions with a rotating stirring device, can solve the problems of inability to achieve material mixing, low rotation speed, and inability to push materials, and achieve the realization of mixing. even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

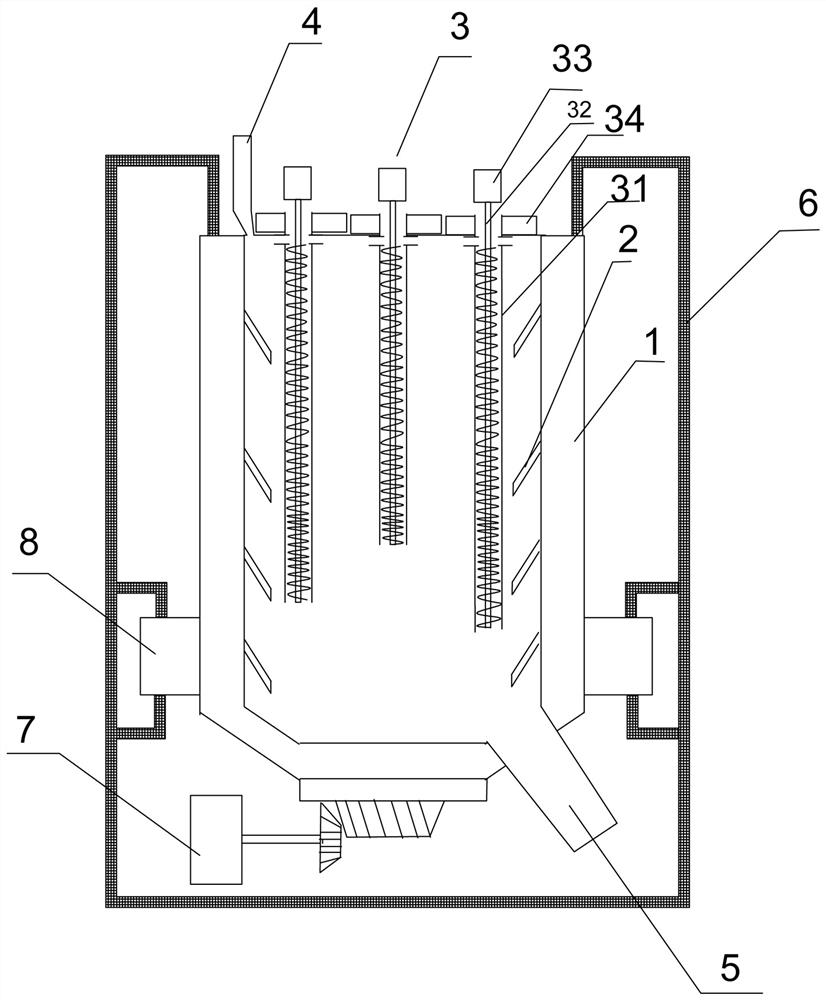

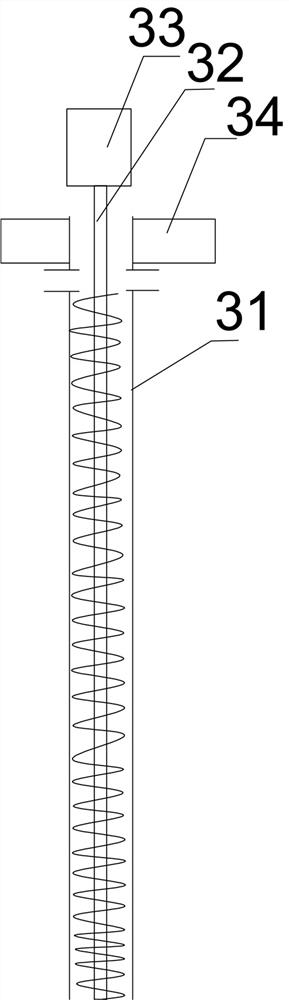

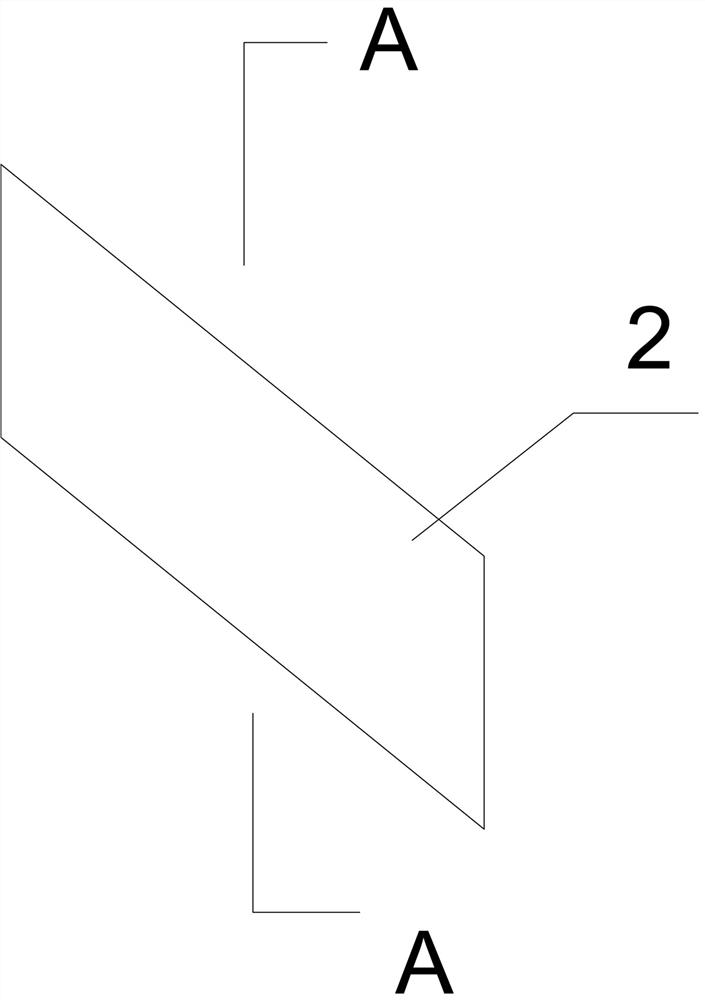

[0029] like figure 1 , 2 Among them, an internal and external disturbance blending device includes a barrel body 1 driven by a motor 7. During operation, the motor 7 drives the barrel body 1 to rotate at a low speed, and the motor 7 drives the screw thread at the lower part of the barrel body 1 through a rotating shaft to rotate the barrel body 1. On the inner wall of the barrel body 1, a disturbance plate 2 is provided, and a limit block 8 is also provided outside the barrel body 1. The limit block 8 can prevent the barrel body 1 from swinging left and right. The lower part of the body 1 is provided with a discharge port 5, the material is fed from the feed port 4, and the stirred material is discharged from the lower discharge port 5. Preferably, the vertical elevation of the connection end between the disturbance plate 2 and the inner wall of the barrel body 1 It is higher than the vertical elevation of the disturbing plate 2 and the inner wall of the barrel body 1 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com