Method for preparing ceramsite filter material from oily sludge

A technology for ceramsite filter material and sludge, which is applied in separation methods, ceramic material production, chemical instruments and methods, etc., to achieve the effects of good environmental protection significance and the spirit of circular economy, cheap and easy-to-obtain raw materials, and short preparation process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A) prepare iron-carrying sludge, respectively weigh hematite powder and sludge (oily sludge produced in crude oil mining, the same below) by mass ratio 4:100, mix and stir to obtain iron-carrying sludge;

[0024] B) preparing de-volatile iron-carrying sludge, introducing the iron-carrying sludge obtained in step A) into a low-temperature plasma reaction tank and continuously exposing air from the bottom of the low-temperature plasma reaction tank (ie, the bottom of the reaction tank), that is, Air was continuously introduced into the tank from the bottom of the low-temperature plasma reaction tank to aerate the iron-carrying sludge in the tank, and at the same time, the iron-carrying sludge in the low-temperature plasma reaction tank was irradiated with low-temperature plasma for 1.5 hours (that is, the irradiation time 1.5h), the plasma action voltage, that is, the low temperature plasma action voltage, is 5kV, and the devolatile active iron-carrying sludge is obtained;...

Embodiment 2

[0043] Only change the mass ratio of hematite powder and sludge in step A) to 6:100; change the low temperature plasma irradiation time in step B) to 1 h, and change the low temperature plasma action voltage to 27.5kV; The mass ratio of calcium oxide powder and perlite powder in step C) was changed to 15:100; The drying temperature was changed to 125°C, the drying time was changed to 7h, and the sintering temperature and time were changed to 1100°C and 20min, respectively. The rest are the same as the description of Example 1.

[0044] The practical application example of the ceramsite filter material obtained in this embodiment to the filtration of landfill leachate is as follows:

[0045] The source of landfill leachate is the same as that in Example 1.

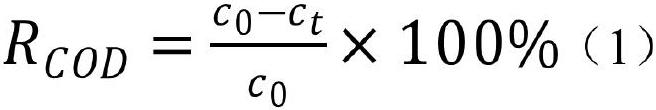

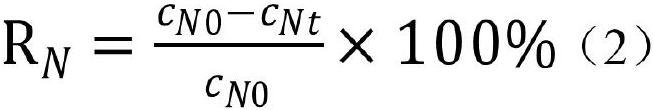

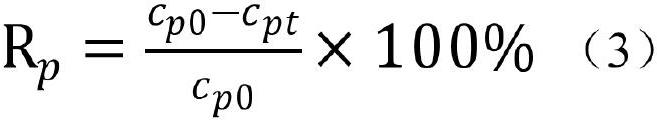

[0046] Landfill leachate filtration test, COD concentration detection and calculation of COD removal rate, ammonia nitrogen concentration detection and ammonia nitrogen removal rate calculation, total phosphorus concentra...

Embodiment 3

[0052] Only the mass ratio of hematite powder and oil sludge in step A) was changed to 2:100; the irradiation time of low temperature plasma in step B) was changed to 1.5h, and the action voltage of low temperature plasma was changed to 50kV; The mass ratio of calcium oxide powder and perlite powder in step C) was changed to 10:100; the mass ratio of calcium-doped perlite powder and devolatile active iron-loaded sludge in step D) was changed to 20:100, and The drying temperature was changed to 150 °C and the drying time was changed to 2 h, and the sintering temperature and time were changed to 1200 °C and 10 min, respectively. The rest are the same as the description of Example 1.

[0053] The practical application example of the ceramsite filter material obtained in this embodiment to the filtration of landfill leachate is as follows:

[0054] The source of landfill leachate is the same as that in Example 1.

[0055] Landfill leachate filtration test, COD concentration dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com