A fully automatic lug trimming device

A trimming device and fully automatic technology, applied in lighting devices, shearing devices, lighting devices, etc., can solve the problems of low degree of automation, poor practicability, time-consuming and labor-intensive, etc., and achieve a high degree of automation, strong practicability, and reduced The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

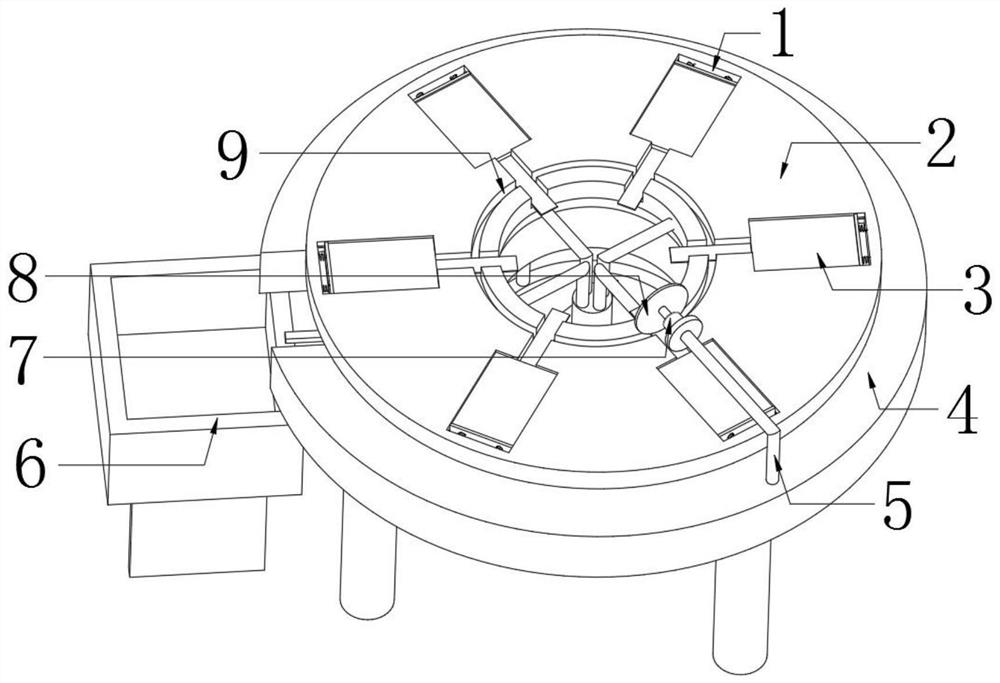

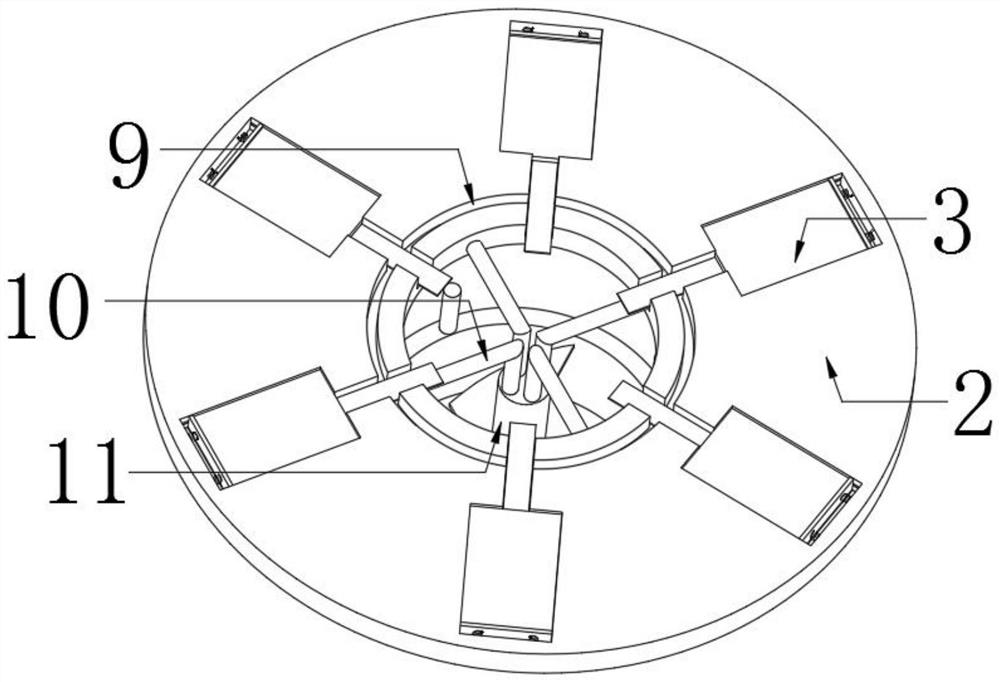

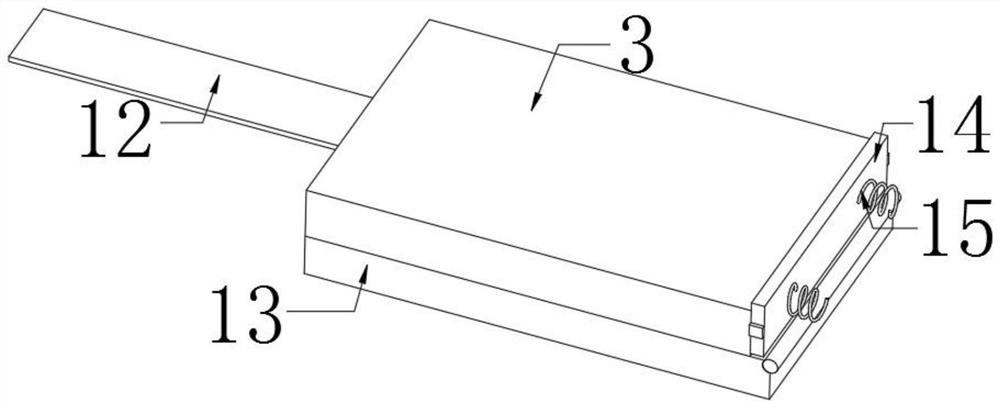

[0029] refer to Figure 1-4 , an automatic pole ear trimming device, including a workbench 4, the bottom outer wall of the workbench 4 is fixed with fixed rods at equal distances by bolts, and the bottom outer wall of the fixed rod is fixed with the same storage cylinder by bolts. The bottom outer wall is fixed with a second motor 20 by bolts, the output shaft of the second motor 20 is connected with a rotating rod 11 through a coupling, and the top outer wall of the rotating rod 11 is fixed with equidistantly distributed connecting rods 10 by bolts. One end is fixed with the same turning plate 2 by bolts, the top outer wall of the turning plate 2 is provided with installation holes 1 distributed at equal distances, the inner wall of the installation hole 1 is fixed with a baffle frame by bolts, and the inner wall of the installation hole 1 is connected by hinges. Plate 13, the top outer wall of the connecting plate 13 is provided with the core 3, the outer wall of one side of...

Embodiment 2

[0040] refer to Figure 5 , an automatic pole ear trimming device, including a workbench 4, the bottom outer wall of the workbench 4 is fixed with fixed rods at equal distances by bolts, and the bottom outer wall of the fixed rod is fixed with the same storage cylinder by bolts. The bottom outer wall is fixed with a second motor 20 by bolts, the output shaft of the second motor 20 is connected with a rotating rod 11 through a coupling, and the top outer wall of the rotating rod 11 is fixed with equidistantly distributed connecting rods 10 by bolts. One end is fixed with the same turning plate 2 by bolts, the top outer wall of the turning plate 2 is provided with installation holes 1 distributed at equal distances, the inner wall of the installation hole 1 is fixed with a baffle frame by bolts, and the inner wall of the installation hole 1 is connected by hinges. Plate 13, the top outer wall of the connecting plate 13 is provided with the core 3, the outer wall of one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com