Full-automatic gear hobbing machining conveying mechanism

A conveying mechanism, fully automatic technology, applied in the direction of gear tooth manufacturing device, gear cutting machine, metal processing equipment, etc., can solve the problems of increased labor cost, labor consumption, inability to automatically arrange tooth embryos, etc., to improve adaptability and stability. , the high degree of automation, the effect of improving practicality and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

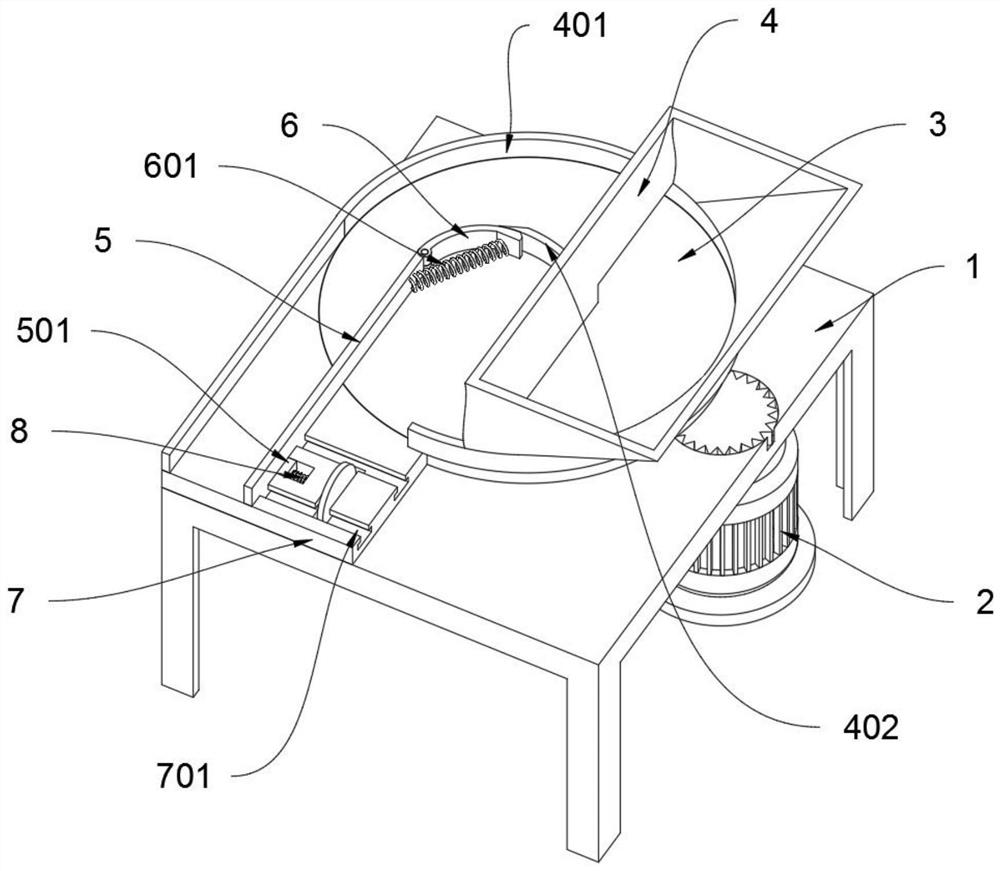

[0028] as attached figure 1 to attach Figure 5 Shown:

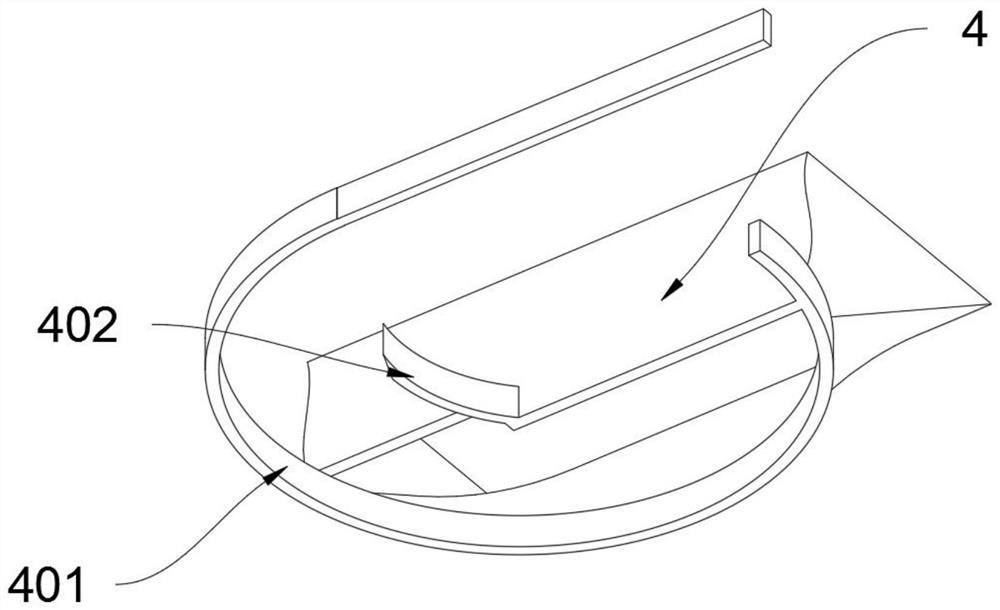

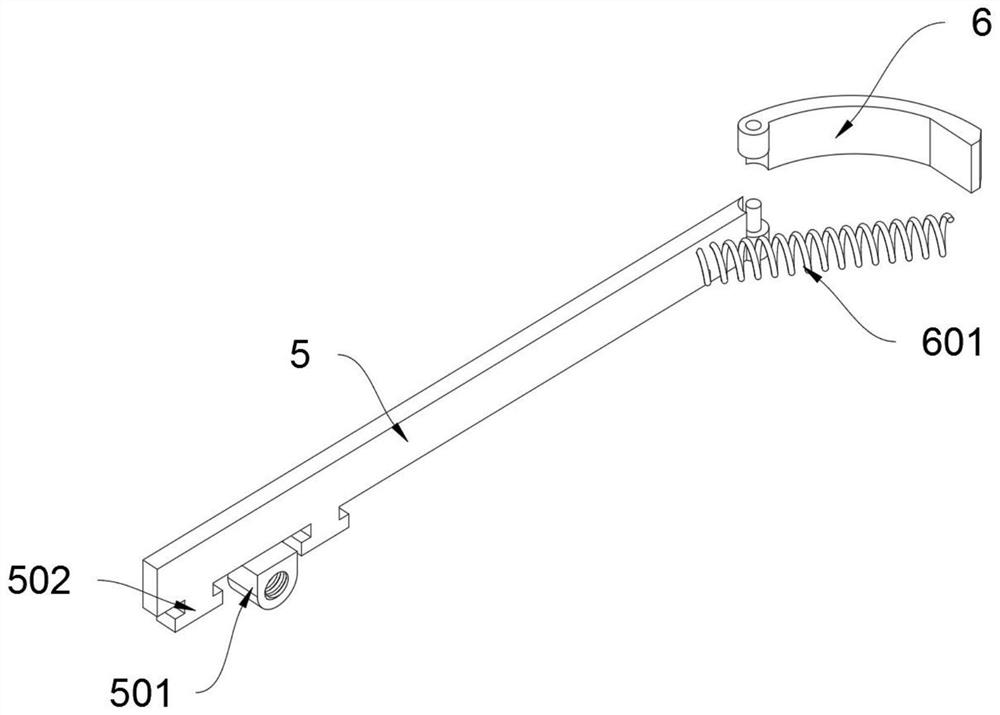

[0029] The invention provides a fully automatic gear hobbing processing and conveying mechanism, comprising a working platform 1, a feeding cover 4, a limit conveying bar 5, a follow-up adjusting bar 6 and a limit adjusting rod 8; the bottom of the working platform 1 is screwed The driving motor 2 is connected and fixed; the driving motor 2 is electrically connected with the external power supply and the control switch, and the driving motor 2 and the conveying roller 3 are connected through gear transmission; the feeding cover 4 is fixed on the top of the working platform 1 by screwing The middle part of the inner bottom surface of the feed cover 4 is provided with a connecting bar 402, and the connecting bar 402 and the follow-up adjustment bar 6 are arc-shaped design, and the follow-up adjustment bar 6 is on the outer side of the connection bar 402, and the follow-up adjustment bar 6 The outer side of the fixed top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com