Intelligent speed regulation welding device

A welding device and intelligent speed regulation technology, applied in welding protection devices, welding equipment, auxiliary devices, etc., can solve the problems of unstable rotation speed and high welding labor intensity, achieve convenient welding operation, reduce welding skill requirements, and weld smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The above-described embodiment only expresses a certain implementation mode of the present invention, and its description is relatively specific and detailed, but it should not be interpreted as limiting the patent scope of the present invention; it should be pointed out that for those of ordinary skill in the art That is to say, without departing from the concept of the present invention, several modifications and improvements can be made, which all belong to the protection scope of the present invention; therefore, the protection scope of the patent for the present invention should be based on the appended claims.

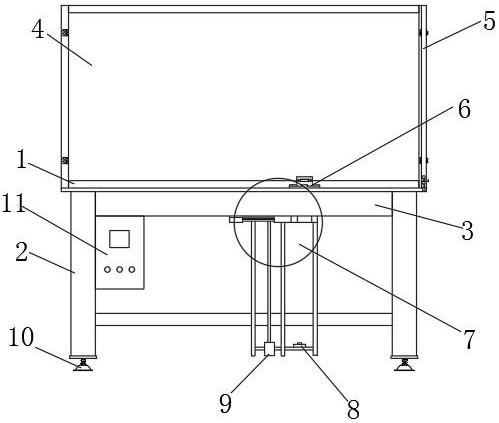

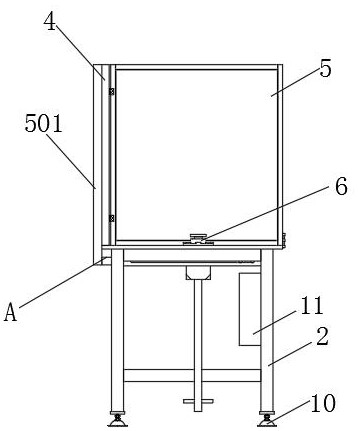

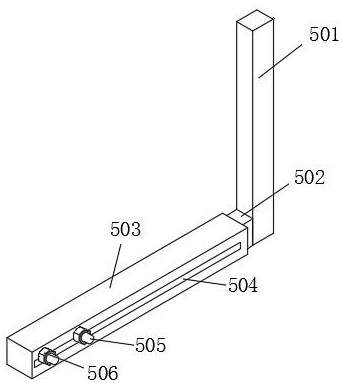

[0034] Refer to attached Figure 1-7 , an intelligent speed-regulating welding device, comprising a work plate 1, the bottom of the work plate 1 is fixedly connected to a support column 2, a plurality of support columns 2 are connected to a transverse plate 3, and the top of the transverse plate 3 is connected to the working plate Plate 1, one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com