Lifting type water-adjusting variable valve

A variable, valve technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of water volume adjustment, poor control accuracy, affecting valve use, valve sealing and leak-proof performance problems, etc., to achieve good water volume control. effect, improving leak-proof sealing, improving sealing and leak-proofing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

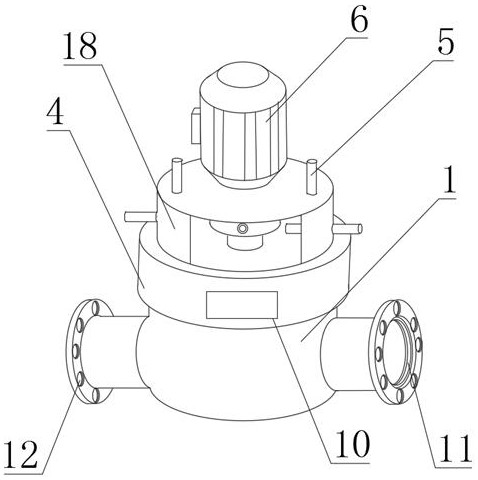

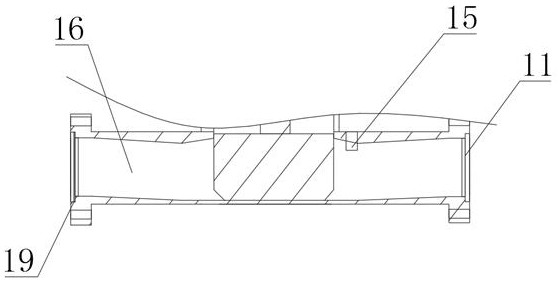

[0021] Example 1 as figure 1 As shown, a pull-type variable water adjustment valve includes a valve main body 1, the right end of the valve main body 1 is provided with a water inlet 2, the left end of the valve main body 1 is provided with a water outlet 3, and the inside of the valve main body 1 is provided with a movable chamber 17. A valve core 14 is provided inside the movable chamber 17, a connecting seat 4 is provided on the upper surface of the valve main body 1, a motor seat 18 is provided on the upper surface of the connecting seat 4, a servo motor 6 is provided on the upper surface of the motor seat 18, and the servo motor The port of 6 is positioned at the top lower end place of motor seat 18 and is provided with shaft coupling 7, and just below shaft coupling 7 is provided with valve stem 9, and the upper surface edge of motor seat 18 and both sides are all provided with positioning rod 5.

Embodiment 2

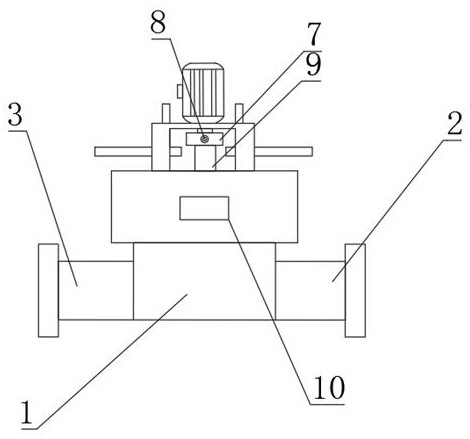

[0022] Embodiment 2 is on the basis of embodiment 1, as figure 2 , 3 As shown, the motor seat 18 is flexibly connected to the servo motor 6, and the valve stem 9 is flexibly connected to the coupling 7. The valve stem 9 extends through the connecting seat 4 to the inside of the valve main body 1 and is connected to the valve core 14. The valve stem 9 and the spool 14 are flexibly connected, which is beneficial to the pulling movement of the spool 14. The positioning rod 5 extends through the motor seat 18 to the inside, and the positioning rod 5 and the motor seat 18 are flexibly connected. The positioning rod 5 The number is several groups, and the front end surface of the coupling 7 is provided with a position sensor 8, and the position sensor 8 and the coupling 7 are flexibly connected, which is beneficial to the fixing and monitoring of the position.

Embodiment 3

[0023] Embodiment 3 is on the basis of embodiment 1, as figure 1 and 3 As shown, the front surface of the connection seat 4 is provided with a flow indicator 10, the flow indicator 10 and the connection seat 4 are flexibly connected, the valve main body 1 is provided with a flow sensing probe 15, and the flow sensing probe 15 and the valve main body 1 are The movable connection is electrically connected between the flow sensor and the flow sensing probe 15, which is beneficial to the control of the water volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com