Device for mixing liquids and solids with liquids by means of vibration

A solid mixing and equipment technology, applied in the direction of shaking/oscillating/vibrating mixers, fluids using vibration, mixers, etc., can solve the problems of no longer economical and practical, large workload, etc., to extend durability and reduce maintenance costs , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

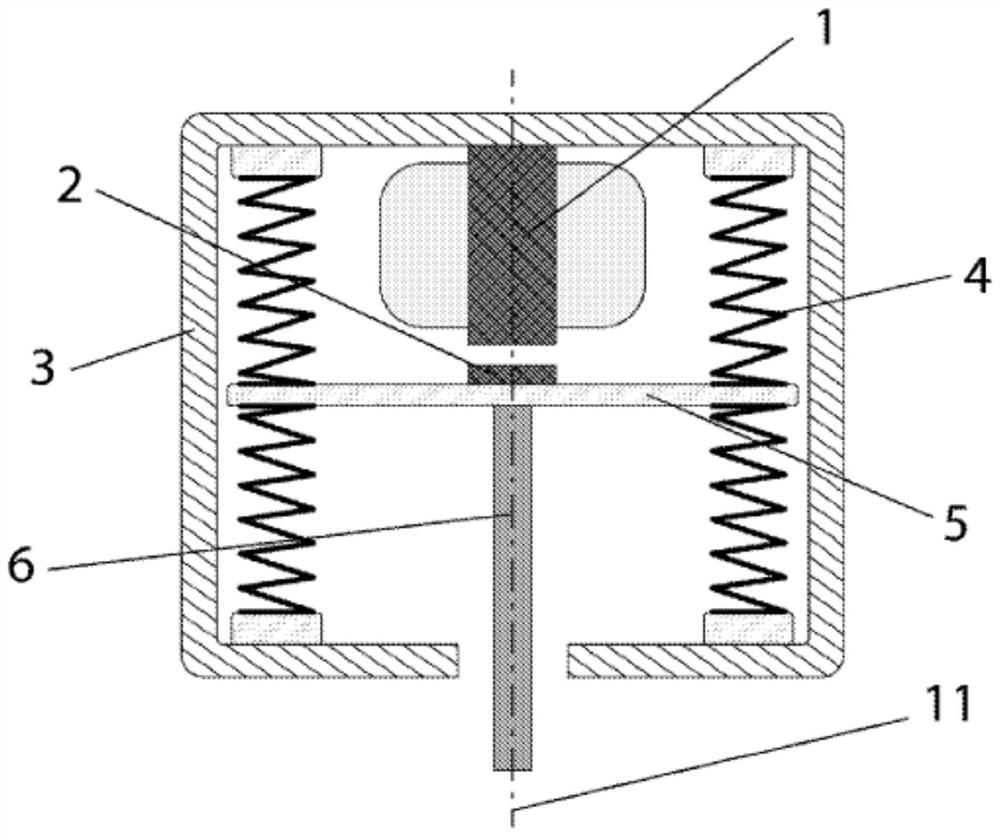

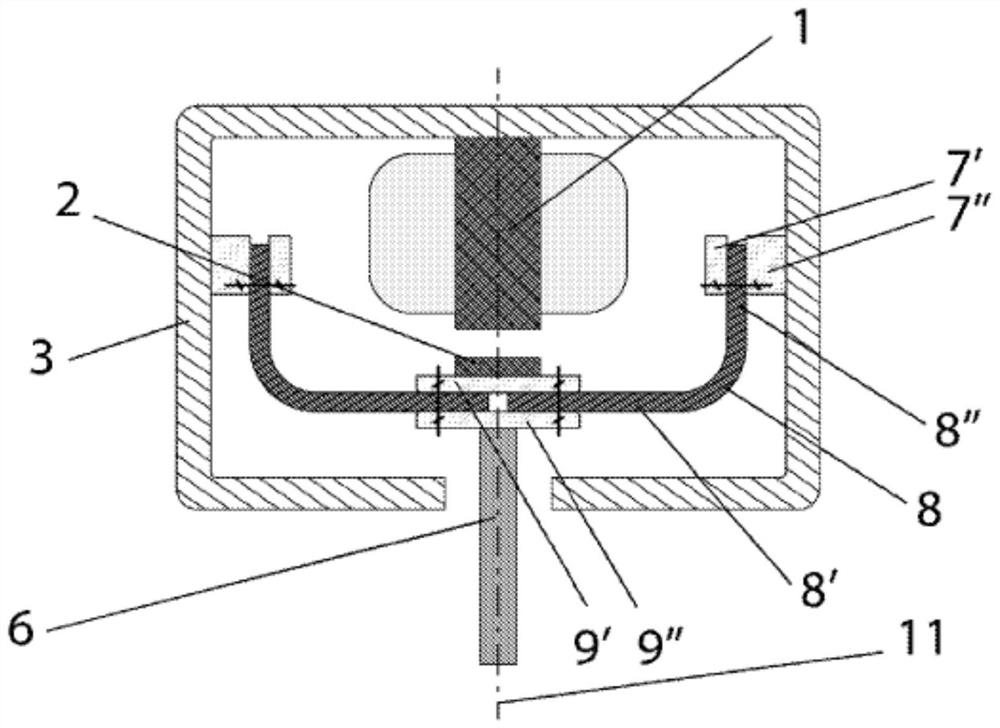

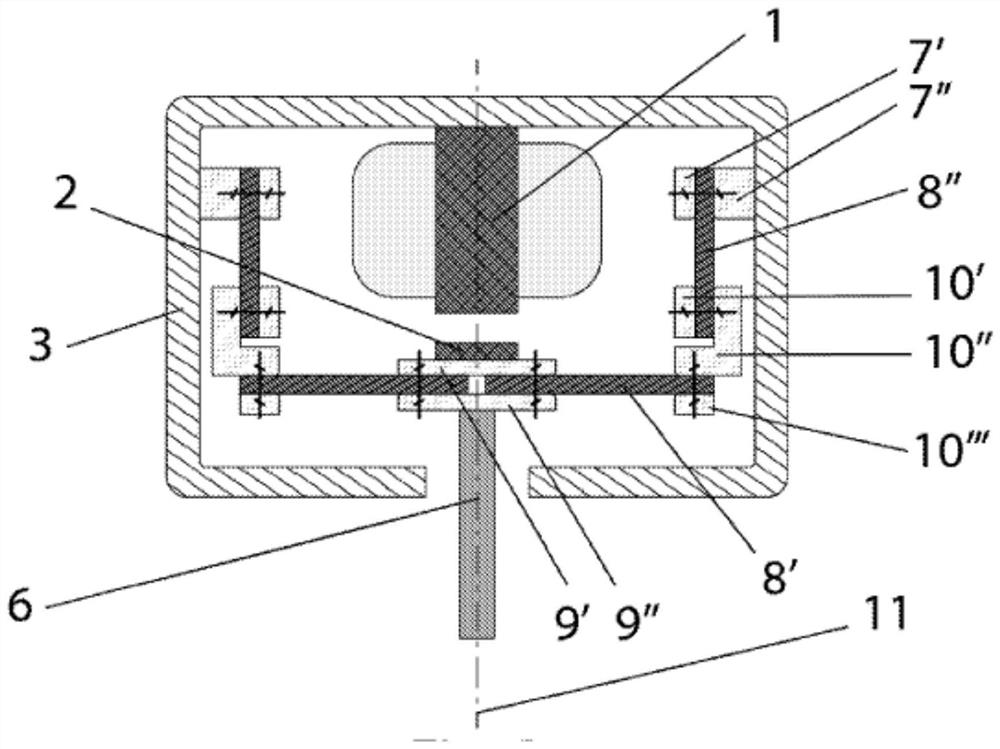

[0025] figure 1A simplified diagram showing the drive of a device for mixing liquids according to the prior art. In this figure, the electromagnetic driver 1 is fixedly connected with the rigid frame frame 3 . Rigid plates 5 are connected and supported by one or more helical springs 4, which can be arranged both in parallel and in series, to ensure optimal support. A permanent magnet or magnetisable element 2 is connected to the plate 5 and is excited by the magnetic coupling of the electromagnet 1 such that the spring 4 is in an oscillating state. The plate 5 is supported by the spring 4 so that it can freely oscillate in the main direction. The main direction along the line 11 is defined by the force of the electromagnet 1 on the permanent magnet or the force of the magnetizable element 2 on the steel plate 5 . The shaft 6 connected to the steel plate then oscillates in the main direction 11 and can transmit the oscillations to the mixing elements fastened to the shaft 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com