Feed mixing device

A mixing device and feed technology, which is applied to feed, mixers with rotating stirring devices, mixers, etc., can solve the problems of poor mixing and separation effects, achieve good mixing effects, and improve the torque of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

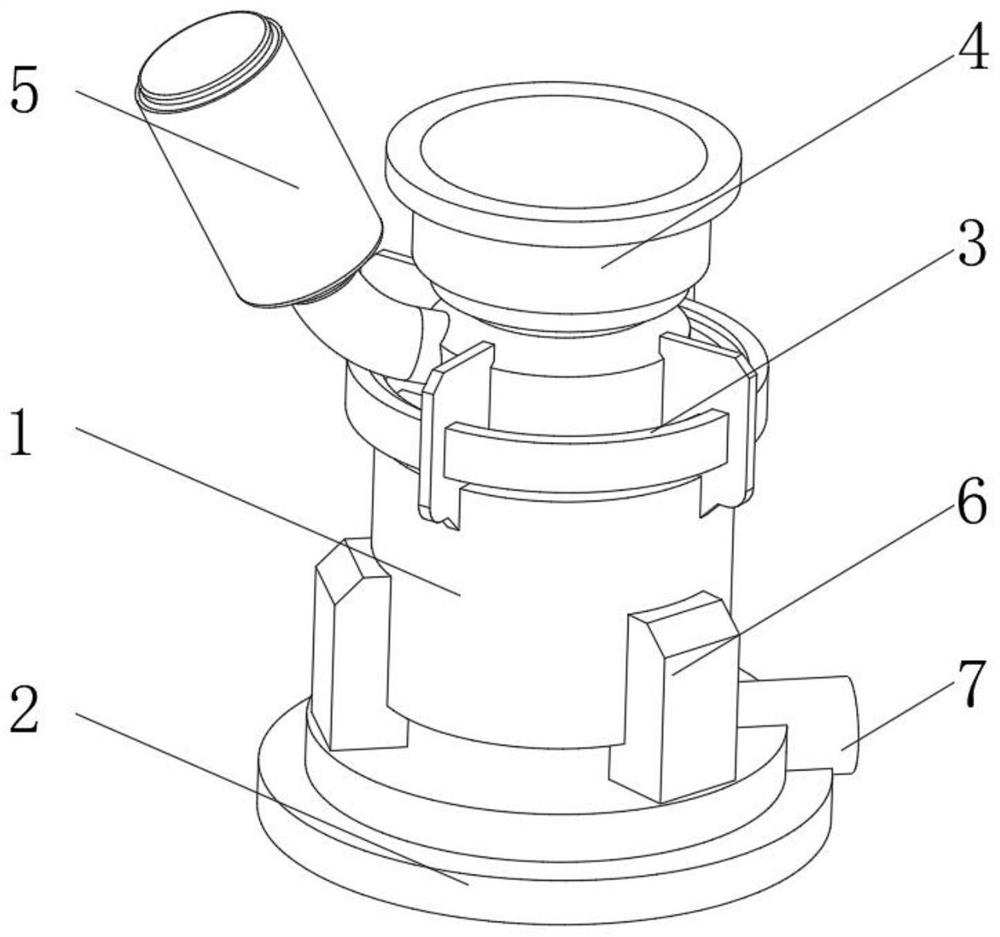

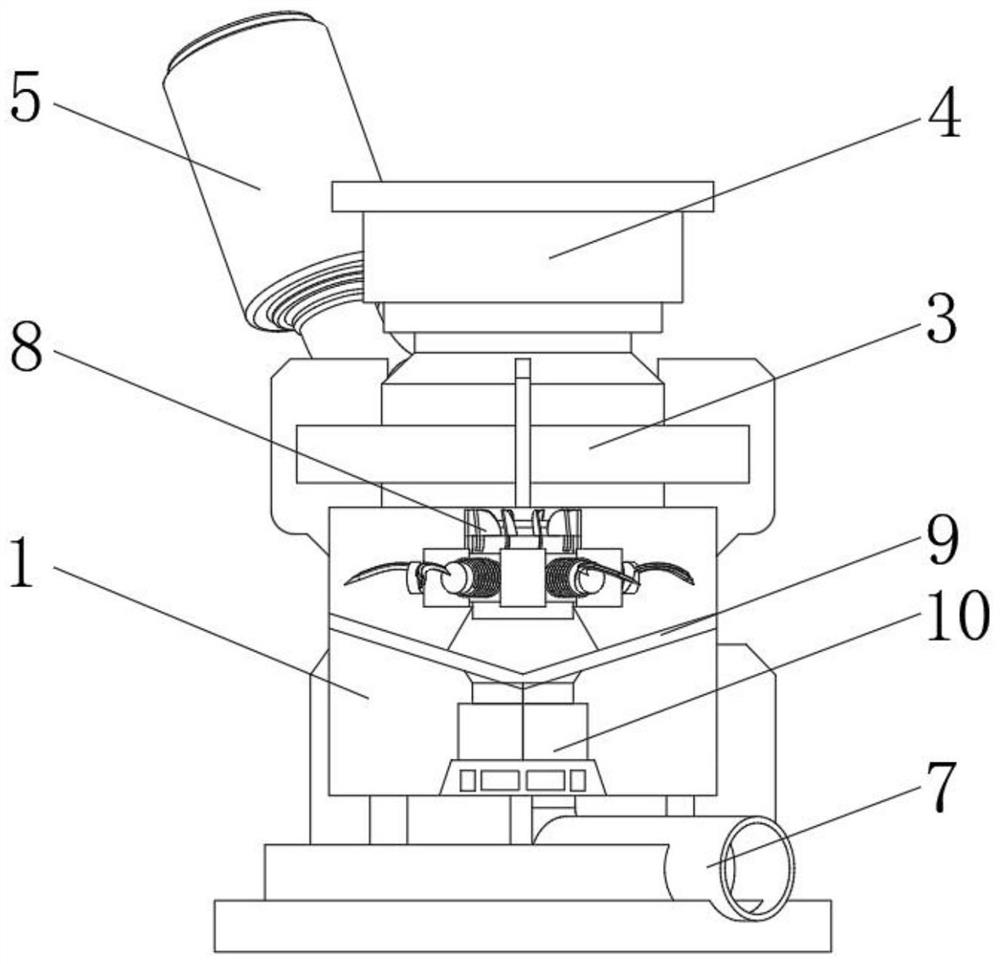

[0032] see Figure 1-2 , the present invention provides a technical solution: a feed mixing device, including a mixing tank 1, the bottom of the mixing tank 1 is fixedly connected with a base 2 by connecting a fixed foot frame 6, and the top of the mixing tank 1 is fixed by connecting a top seat 3 The top feed hopper 4 is connected, the top side of the mixing tank 1 is provided with a solvent liquid tank 5, and the outer discharge pipe 7 is arranged between the bottom of the mixing tank 1 and the base 2, and the outer discharge pipe 7 extends to the outside of the base 2. The top of the row pipe 7 communicates with the bottom of the mixing tank 1, the inner bottom of the mixing tank 1 is provided with a driving mechanism 10, the centrifugal filter disc 9 is installed above the driving mechanism 10, and the upper part of the mixing tank 1 is provided with a power motor. The output end is equipped with a mixing impeller 8, the mixing impeller 8 is located above the centrifugal f...

Embodiment example 2

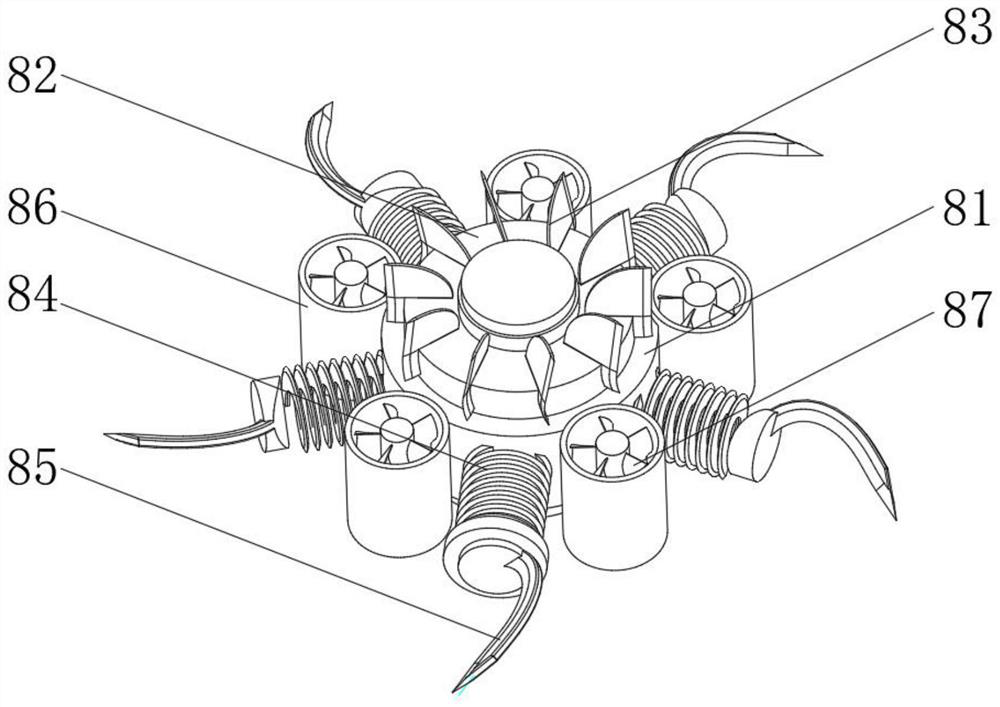

[0034] see Figure 1-4, on the basis of the implementation case 1, the present invention provides a technical solution: the mixing impeller 8 includes an inner disc body 81 and an outer rotating cylinder 86, the outer rotating drum 86 is evenly installed outside the inner disc body 81, and the inner disc body 81 passes through the upper disc The body 82 is equipped with an upper rotary vane 83, and the inner bottom of the outer rotary cylinder 86 is provided with a small motor. The purpose of the small composite impeller 87 is to uniformly mix the internal feed, and the small composite impeller 87 is mainly used for mixing liquid fertilizers. Multiple internal spirals can mix the internal fertilizer more evenly. By setting different rotation directions, it can also make The inner multiple spiral flow is reversed, and the mixing effect is better.

[0035] A space is provided between the outer rotating cylinders 86, and a spiral spring knife 84 is installed on the outer side of...

Embodiment example 3

[0038] see Figure 1-7 , on the basis of implementation case 1 and implementation case 2, the present invention provides a kind of technical scheme: centrifugal filter disc 9 comprises filter disc body 91, and the inner side of filter disc body 91 is provided with processing inner tank 92 and direct separation filter tank 94, processing A rotary treatment terminal 93 is arranged on the inner side of the inner tank 92, a filter separation arc knife 97 is arranged in the middle of the inner side of the inner tank 92, and a centrifugal separation filter hole 96 is arranged on the inner side of the inner tank 92 to directly separate the inside of the filter tank 94. A straight filter hole 95 is provided, and the center of the filter disc body 91 is provided with an outer row center hole, and an electromagnetic switch valve is installed at the bottom of the outer row center hole.

[0039] The rotary processing terminal 93 includes a circular terminal body 931 and a central shaft 93...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com