Automatic heating dispensing valve

An automatic heating and dispensing valve technology, applied in tobacco, devices for coating liquids on surfaces, food science, etc., can solve the problems that the bubbles in the latex are not easy to eliminate production, affect the production progress, and inconvenient to clean, etc., and reach the reduction point. The possibility of glue interruption, the effect of improving efficiency and reducing the waste rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

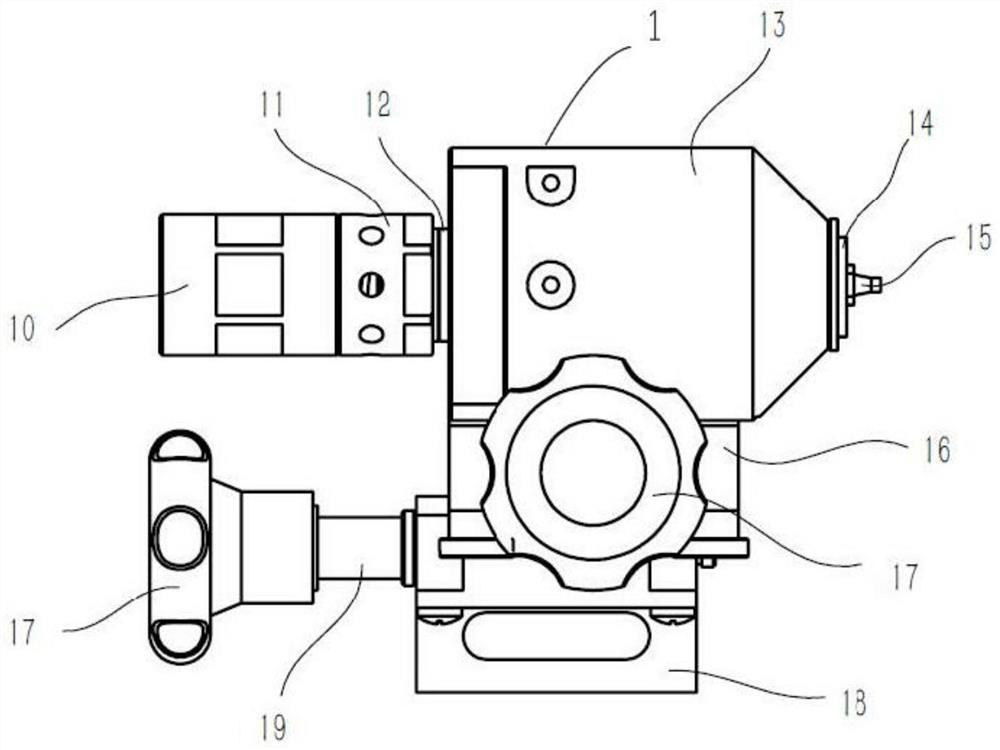

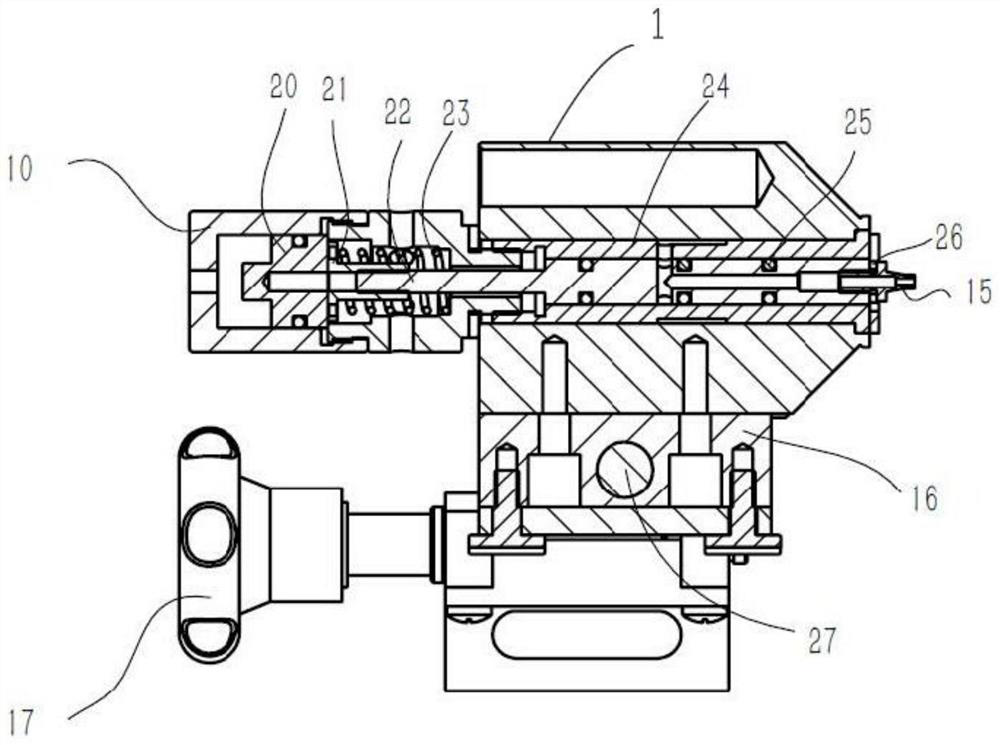

[0026] In order to make the techniques of the present invention, the creation characteristics, the achievements and efficacy are readily understood, and the invention is further clarified in conjunction with the specific drawings.

[0027] It should be noted that in the present invention, when the element is referred to as "fixed to" another element, it can be directly in another element or may also exist. When a component is considered to be "connected" another element, it may be directly connected to another element or may always exist in the center element. The term "vertical", "horizontal", "left", "right", "left", "right", and similar expressions as used herein are intended to illustrate the unique embodiment.

[0028] All techniques and scientific terms used herein are identical to those skilled in the art, unless otherwise defined. The terms used in the specification of the present invention are merely intended to describe specific embodiments, not intended to limit the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com