Laser SLAM-based automatic positioning and punching device for building construction

A technology of construction and punching device, applied in positioning device, feeding device, storage device, etc., can solve the problems of automatic judgment of punching position, low efficiency, and increase of labor force of construction workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

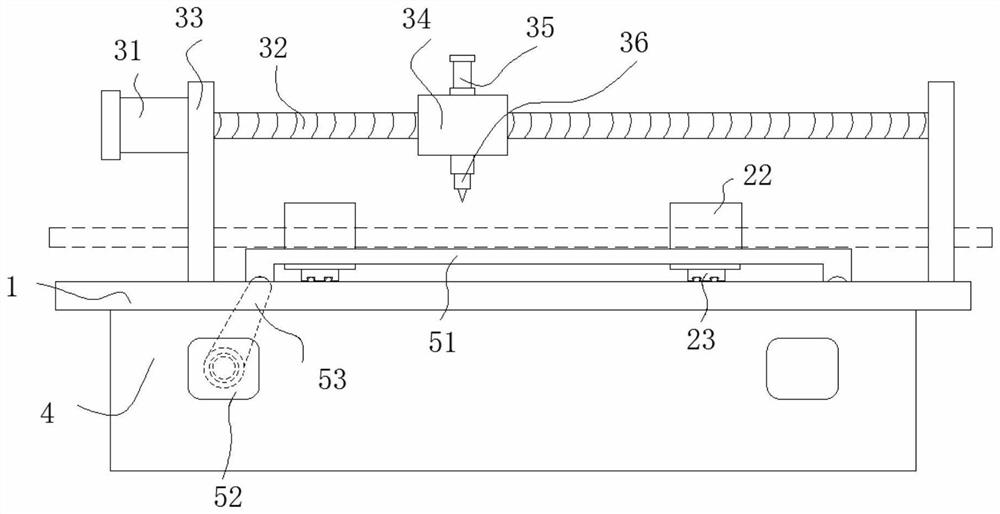

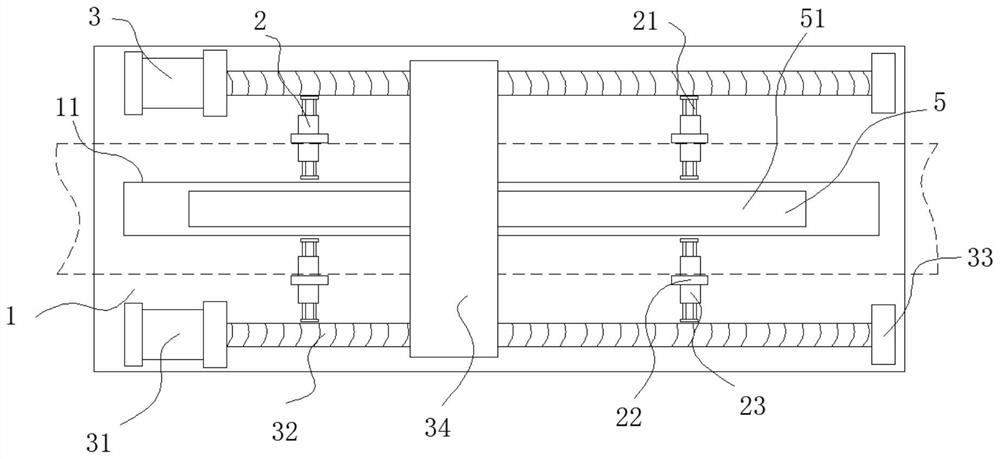

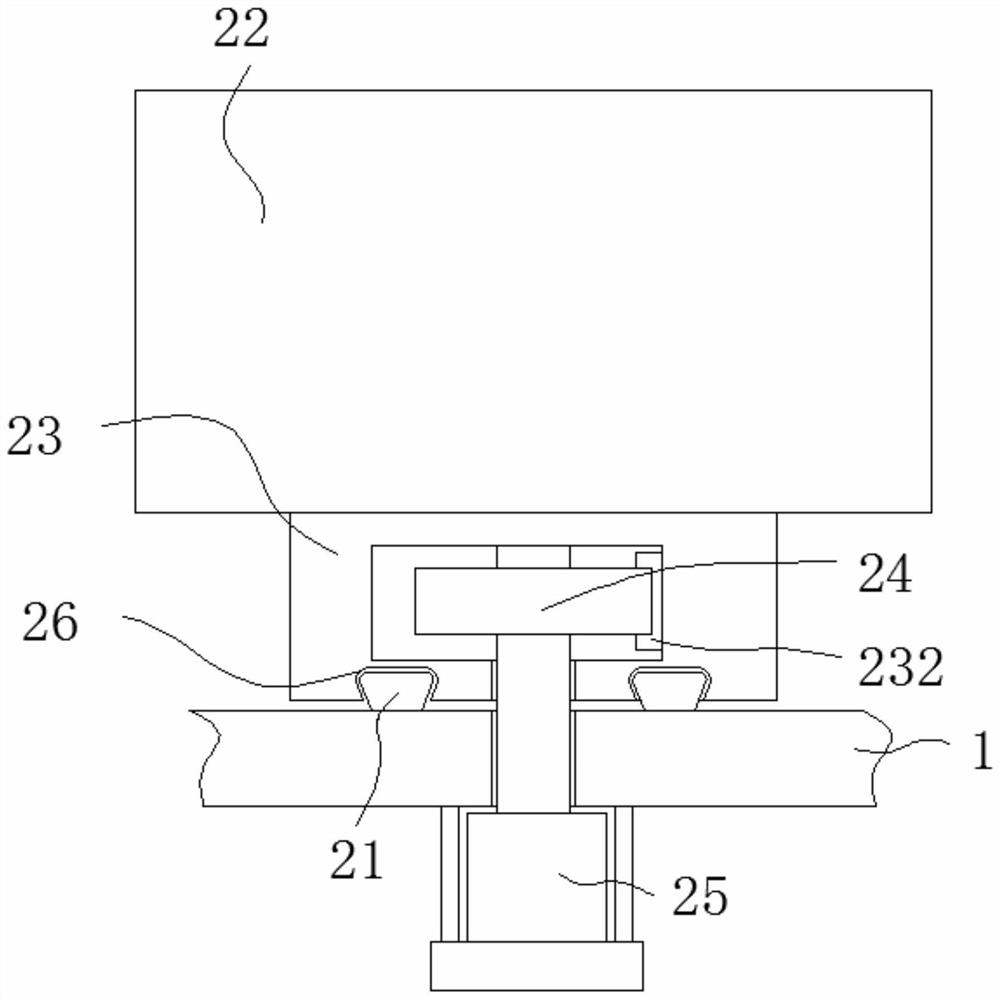

[0034] Embodiment: When using the punching device, first mark the plate with chalk, then use the positioning mechanism 2 to clamp the plate and adjust the lateral position of the plate, then use the punching mechanism 3 to punch holes, and the feeding mechanism 5 to carry out the punching. Intermittent feeding, the lubricating mechanism 6 lubricates and cools the punching head 36, and supplies lubricating oil intermittently with the feeding mechanism 5, the variable diameter assembly 7 is used to change the diameter of the punching, and the plate is fed from left to right to complete the processing process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com