Bamboo chip fixed-length cutting equipment for wooden toy manufacturing

A technology of cutting equipment and wooden toys, which can be used in mechanical equipment, manufacturing tools, wood processing utensils, etc., and can solve the problem of inconvenient collection of bamboo chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

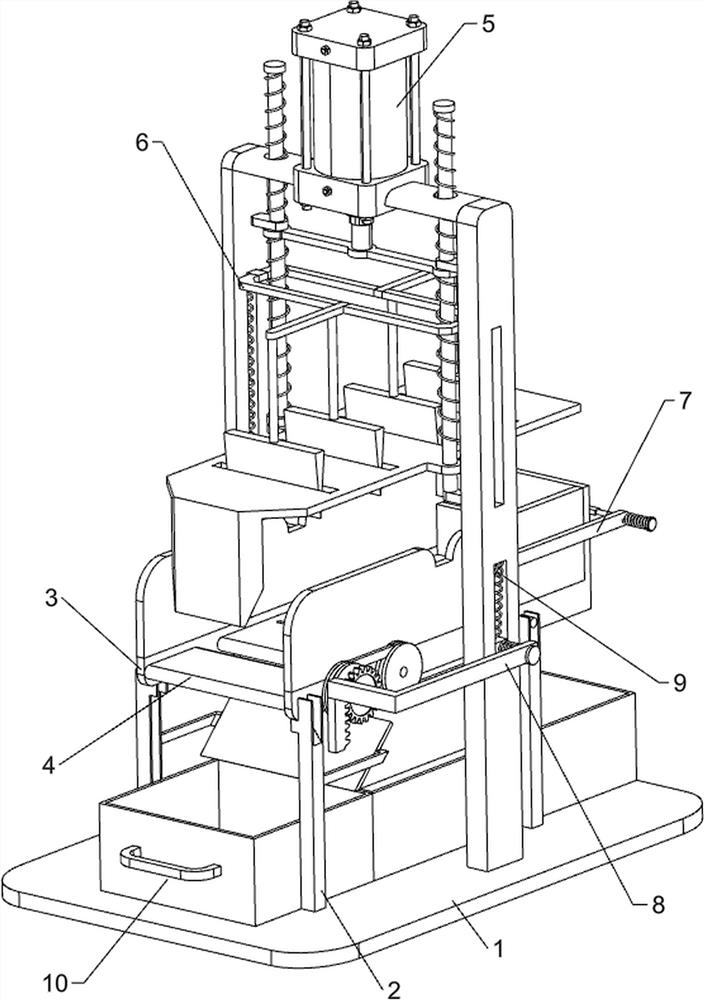

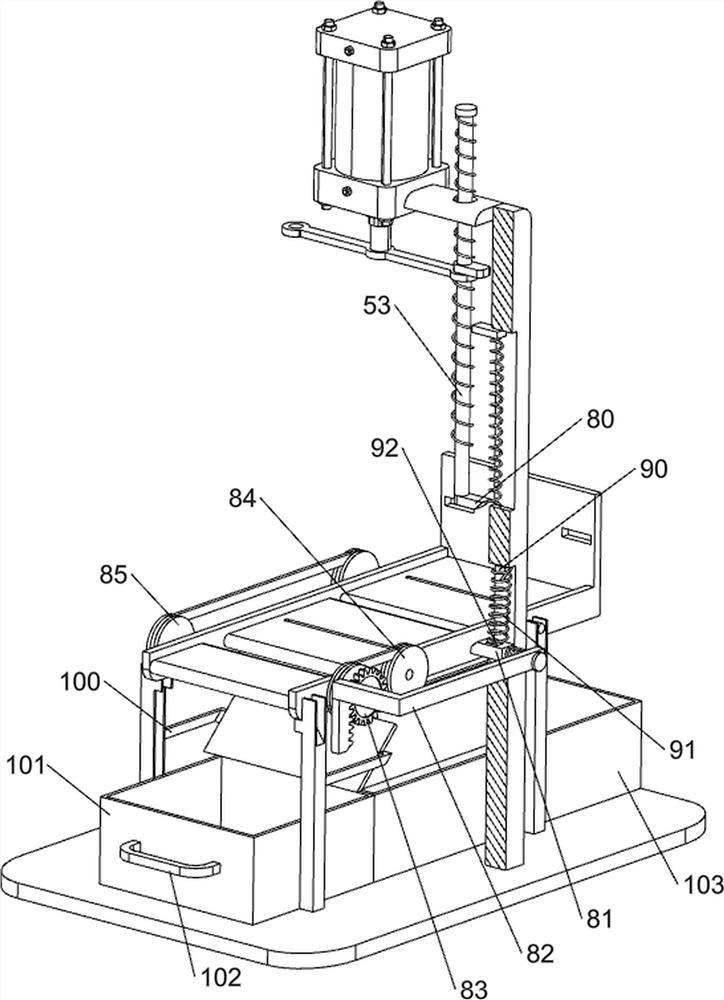

[0024] A kind of bamboo chip fixed-length cutting equipment for wooden toys, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base plate 1, a support 2, a fixing seat 3, a placement mechanism 4, a pressing mechanism 5 and a cutting mechanism 6. The base plate 1 is provided with a plurality of supports 2, and between the supports 2, a fixing seat 3 is provided. 3. The upper rotary type is provided with a placing mechanism 4, the bottom plate 1 is provided with a pressing mechanism 5, and the pressing mechanism 5 is provided with a cutting mechanism 6.

[0025] When people need to use this equipment, first people place the bamboo slices on the placement mechanism 4, then the pressing mechanism 5 can be started, and the pressing mechanism 5 then drives the cutting mechanism 6 to operate. When the bamboo slices touch, the cutting mechanism 6 cuts the bamboo slices. When the cutting is completed, people can drive the cutting mechanism 6 to reset thro...

Embodiment 2

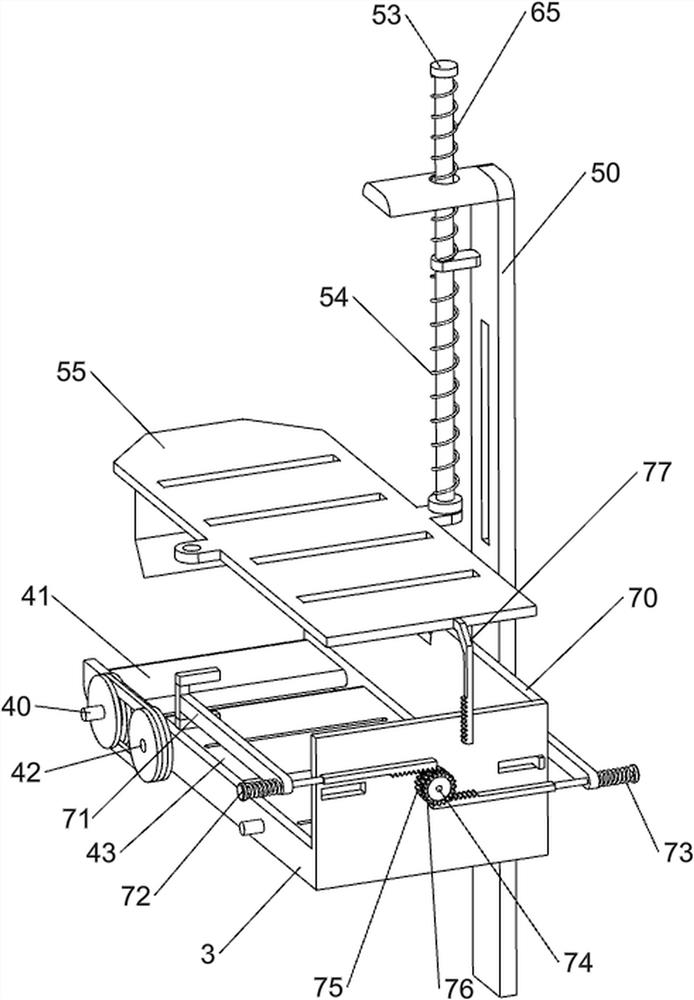

[0033] On the basis of Example 1, such as figure 1 , image 3 and Figure 4 Shown, also comprise clamping mechanism 7, clamping mechanism 7 comprises movable plate 70, push rod 71, first rack 72, the 4th spring 73, the 4th rotating shaft 74, the first full gear 75, the second full gear 76 and the second tooth bar 77, on the fixed seat 3, the forward and backward symmetrical sliding type is provided with movable plate 70, and movable plate 70 is all provided with push rod 71, and the all sliding type on the right side of push rod 71 is provided with first tooth bar 72, pushes A fourth spring 73 is provided between the rod 71 and the first rack 72, and the right side of the fixed base 3 is rotated to be provided with a fourth rotating shaft 74, the fourth rotating shaft 74 is provided with the first full gear 75, and the fourth rotating shaft 74 is provided with a first full gear 75. There is a second full gear 76, the second full gear 76 is located on the right side of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com