Foam plastic device for manufacturing ultralow-energy-consumption building heat preservation plate

A technology for building thermal insulation and energy consumption, applied in applications, flat products, household appliances, etc., can solve the problems of inconvenient operation of steel trusses, inability to flexibly adjust the width of plates, and inability to form and splicing tongue and groove at one time, saving raw materials and labor. Effects of cost, resizing, flexible sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

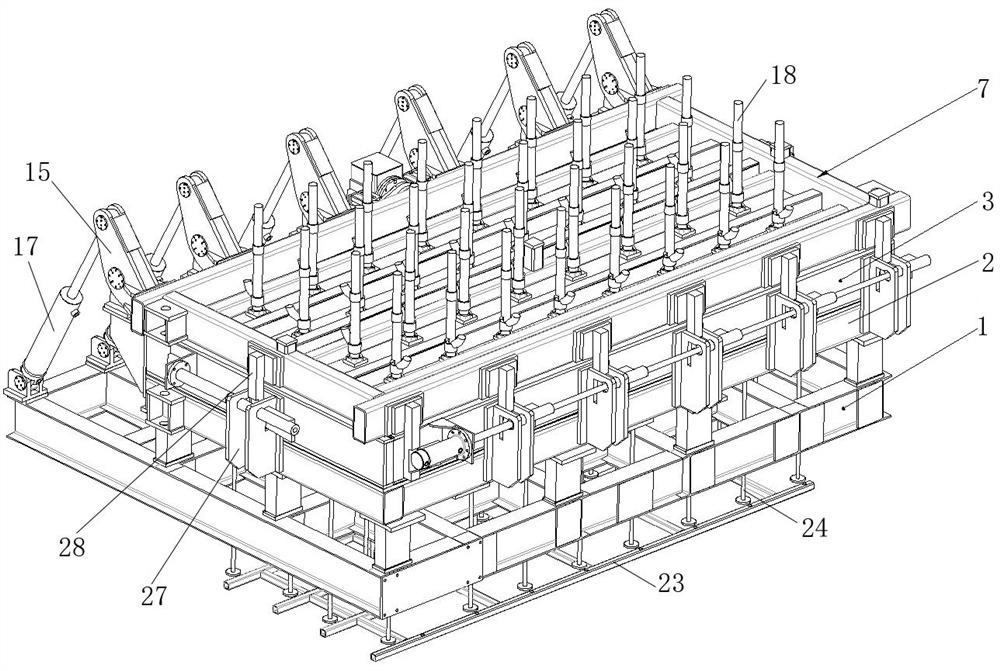

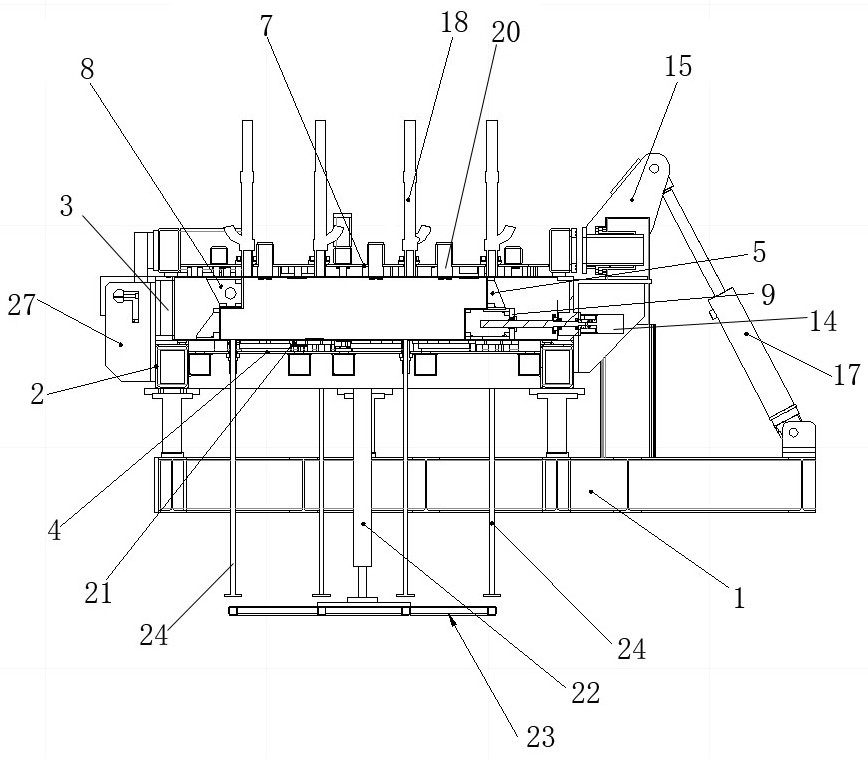

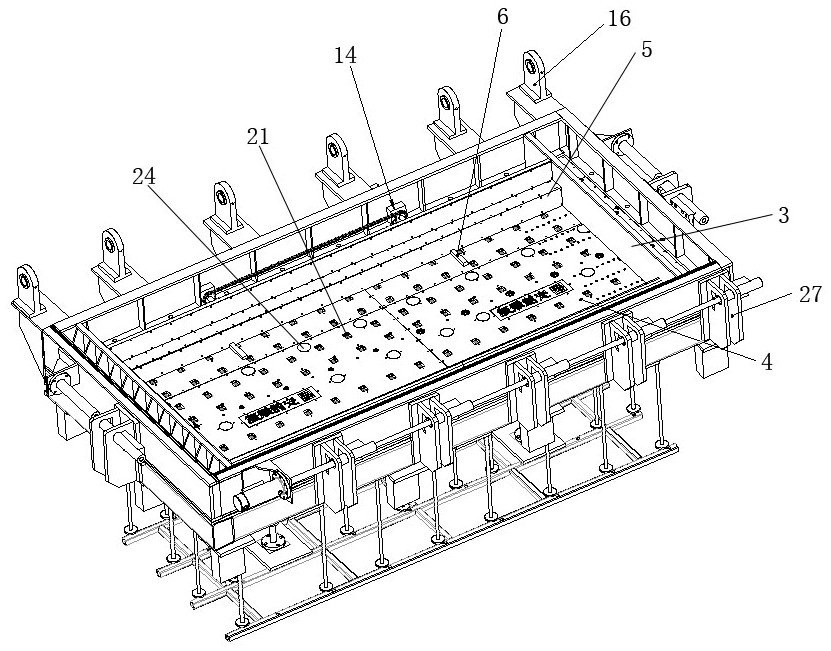

[0022] In order to have a clearer understanding of the technical features, purpose and effects of the present invention, the specific implementation, structure and features of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0023] see Figure 1-Figure 9 As shown, the present invention provides a foam molding device for making ultra-low energy consumption building insulation boards, including a bottom bracket 1, a mold cavity base installed above the bottom bracket, and a mold cavity covered above the mold cavity base Cover, the mold cavity upper cover side is hingedly connected with the mold cavity base side and the mold cavity upper cover can be turned backwards to open; the mold cavity base includes a mold cavity support frame 2, a square frame-shaped Cavity frame 3, cavity bottom plate 4 positioned at the bottom of the cavity frame, the cavity bottom plate 4 is positioned at the inner bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com