PCB character ink-jet printer

An inkjet printer, character technology, applied in typewriters, printing devices, printing and other directions, can solve the problems of low printing efficiency, inability to clean the print head, low printing accuracy, etc., and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

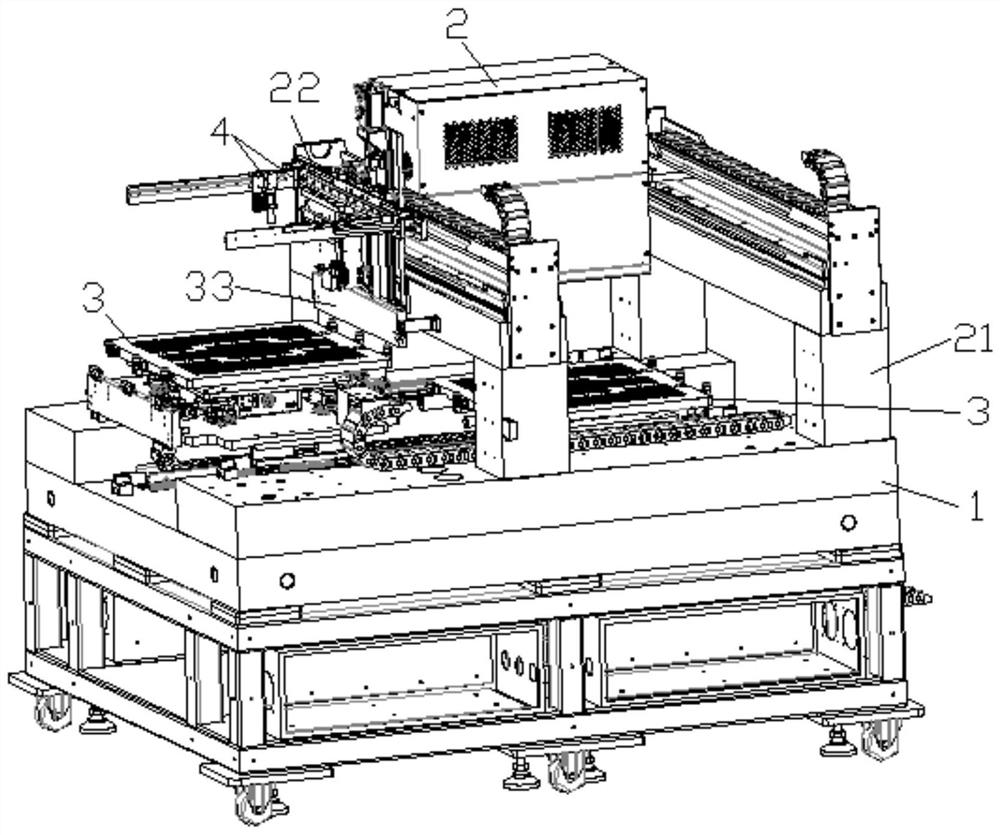

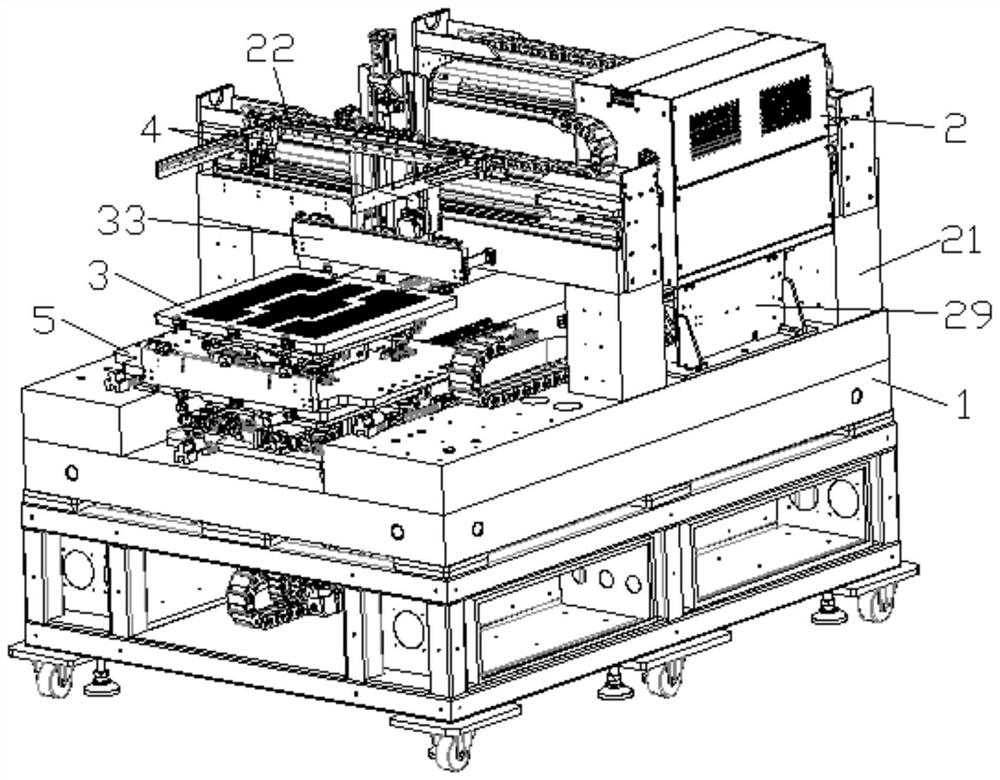

[0047] Such as figure 1 with figure 2 As shown, on the basis of the above structure, this embodiment also includes a controller and a detection device for detecting whether the PCB board on the platform 3 is placed correctly. The bottom of each platform 3 is equipped with an adjustment device for adjusting its orientation. The device, the detection device and the plurality of adjustment devices are respectively connected with the controller in communication. When printing, the detection device first detects whether the PCB board on the platform 3 is placed correctly, and sends the corresponding signal to the controller, and the controller receives the corresponding signal processing and analysis; when the PCB board is placed incorrectly, the controller controls multiple The adjusting device adjusts the angle of the platform 3, thereby adjusting the angle of the PCB board and improving the printing accuracy.

[0048] It should be noted that the PCB board is placed on the pla...

Embodiment 2

[0050] On the basis of Embodiment 1, in this embodiment, the detection device includes at least one camera 4, and the camera 4 is connected to the controller in communication. It is located below the camera 4 (to ensure that the camera 4 can collect the information of the PCB on the platform 3, such as the orientation). When printing, the camera 4 collects the picture of the PCB board on the platform, and sends the corresponding information to the controller. The controller receives the corresponding information and processes and analyzes it to determine whether the position of the PCB board is correct.

[0051] Preferably, the above-mentioned camera 4 adopts a CCD camera, which has better acquisition effect and higher simplicity and accuracy.

[0052] In addition, the number of cameras 4 is preferably two, and the specific installation method of the two cameras 4 is: a motor is fixedly installed on the above-mentioned mounting frame 21, and the output end of the motor extends...

Embodiment 3

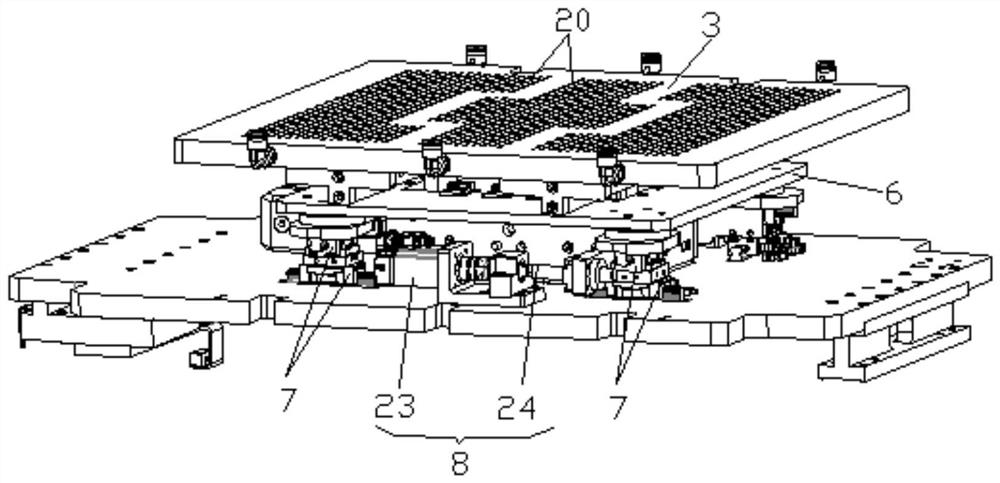

[0055] Such as Figure 3 to Figure 6 As shown, on the basis of Embodiment 1, in this embodiment, each adjusting device includes a base 5 and a fixed plate 6, and the base 5 is installed on the printing table 1 for horizontal movement back and forth, and its two sides are respectively connected with the corresponding two The slide rails are slidingly matched; the base 5 is evenly spaced with a plurality of adjustment mechanisms, and the fixed plate 6 is horizontally fixed and installed on the plurality of adjustment mechanisms; the platform 3 is horizontally installed on the fixed plate 6 and can move up and down. When in use, the position of the fixed plate 6 is adjusted through multiple adjustment mechanisms, thereby adjusting the angle of the platform 3 and the PCB board, so as to improve the printing accuracy; in addition, the platform 3 can move up and down, so as to better cooperate with the print head 2, Improve the effect of printing.

[0056] The above-mentioned fixin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap