Heavy transmission shaft middle bracket assembly with rubber vulcanized on bearing outer ring

A bearing outer ring and rubber vulcanization technology, which is applied in non-rotational vibration suppression, control devices, transportation and packaging, etc., can solve the problems of parts processing, cumbersome assembly, heavy parts, heavy weight, etc., to reduce weight and prevent prolapse , The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

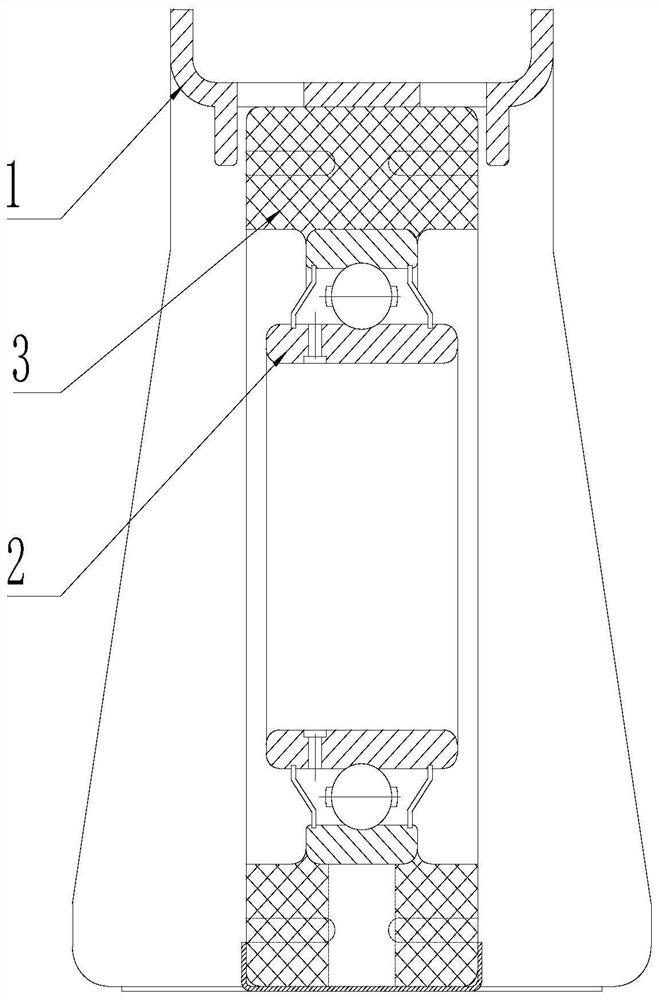

[0015] Example: as attached figure 1 As shown, the heavy-duty transmission shaft intermediate bracket assembly with rubber vulcanized on the outer ring of the bearing includes a fixed bracket 1 and a ball bearing 2. The outer ring of the ball bearing 2 is vulcanized with a rubber cushion 3 at a low temperature, so that the ball bearing 2 It forms an integrated structure with the rubber buffer pad 3, and the ball bearing 2 is directly installed and fixed with the fixing bracket 1 through the rubber buffer pad 3.

[0016] The present invention vulcanizes the rubber buffer pad 3 of the intermediate bracket assembly of the heavy-duty transmission shaft directly on the outer ring of the ball bearing 2 through the rubber low-temperature vulcanization process, and cancels the bearing seat and snap ring, so that the rubber buffer pad 3 and the ball bearing 2 are Integrated structure, no interference fit between the ball bearing 2 and the rubber cushion 3, can effectively control the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com