Round tube air chamber car intercooler

A technology of air chambers and round tubes, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of high mold manufacturing cost, low production efficiency, and high cost, shorten the production process route, reduce material consumption, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

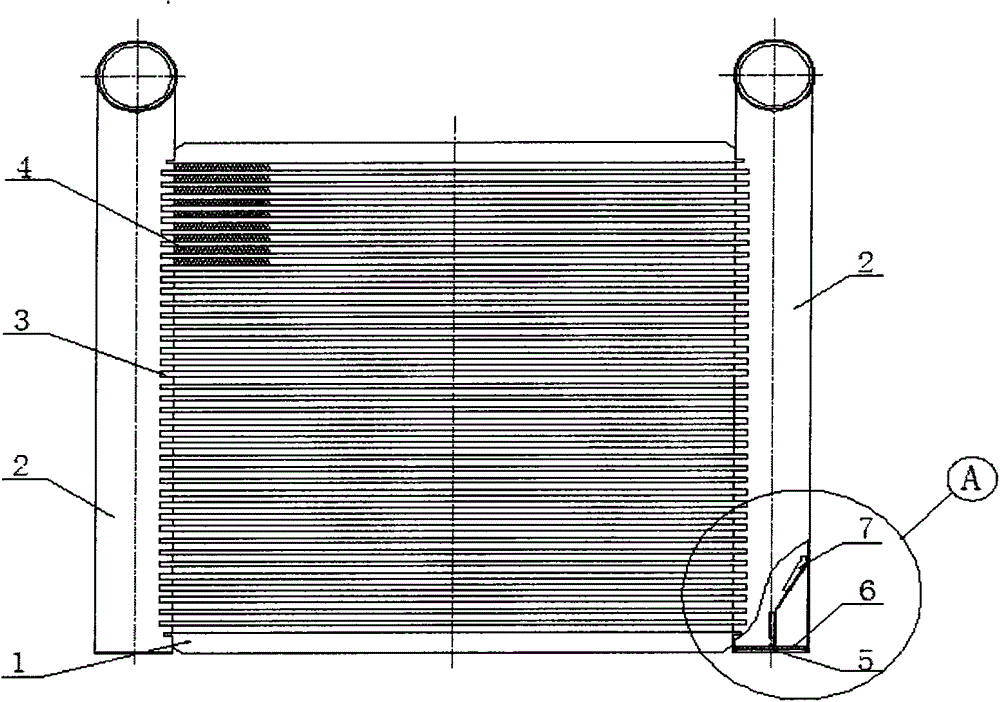

[0030] exist figure 1 , figure 2 In the shown embodiment, the circular tube air chamber (2), side plate (1), cooling pipe (3), heat dissipation strip (4), blocking cover (6), deflector plate (7) and rivet (5) are sequentially Assembled, the overall brazing connection is completed once through the nitrogen protection brazing furnace.

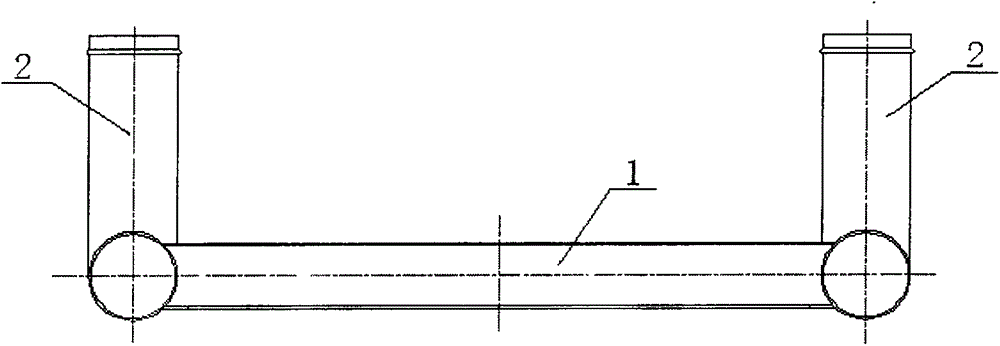

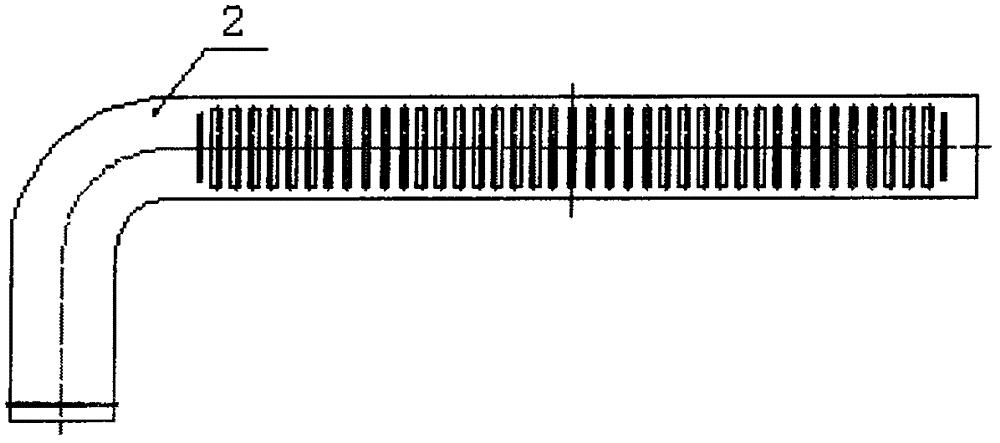

[0031] exist image 3 , Figure 4 In the shown embodiment, one end of the aluminum round tube is machined with a backstop convex rib, and the end is bent according to the required angle, and the cooling pipe installation hole and the side plate installation are processed on the position specified in the straight section of the round tube. hole.

[0032] exist Figure 5 , Figure 6 , Figure 7 , Figure 8 with Figure 9 Among them, the deflector (7) is fixed on the block cover (6) with rivets (5), and installed on the round tube air chamber (2) in the specified order and position. After the assembly of the intercooler assembly is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com