Sand spraying process for improving initial skid resistance of SMA pavement

A technology of anti-slip performance and sand spraying, which is applied in the field of sand spraying technology, and can solve the problems of insufficient initial anti-slip performance of SMA pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

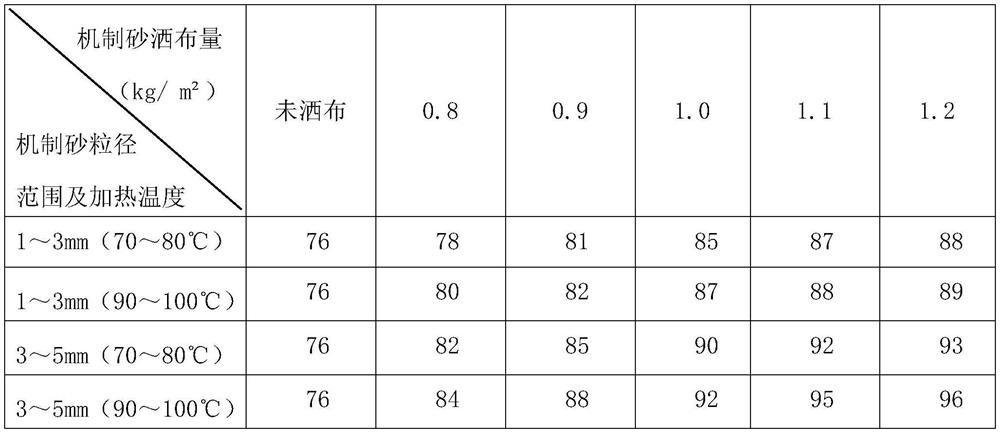

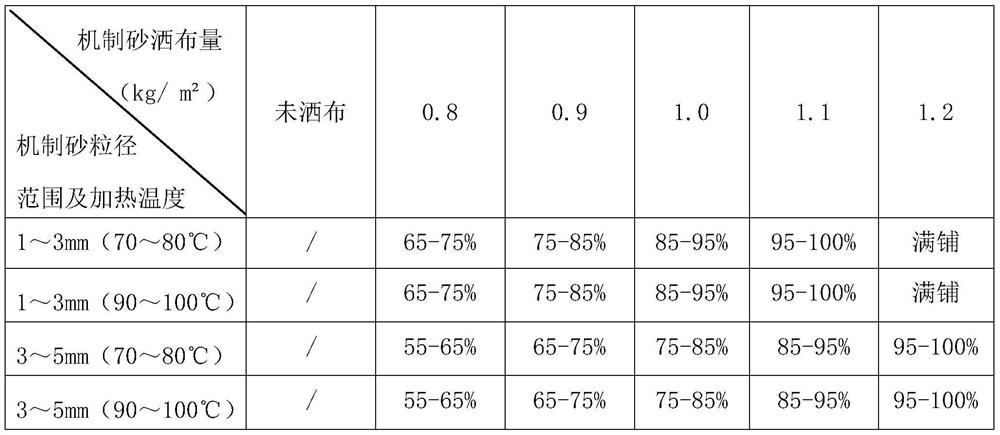

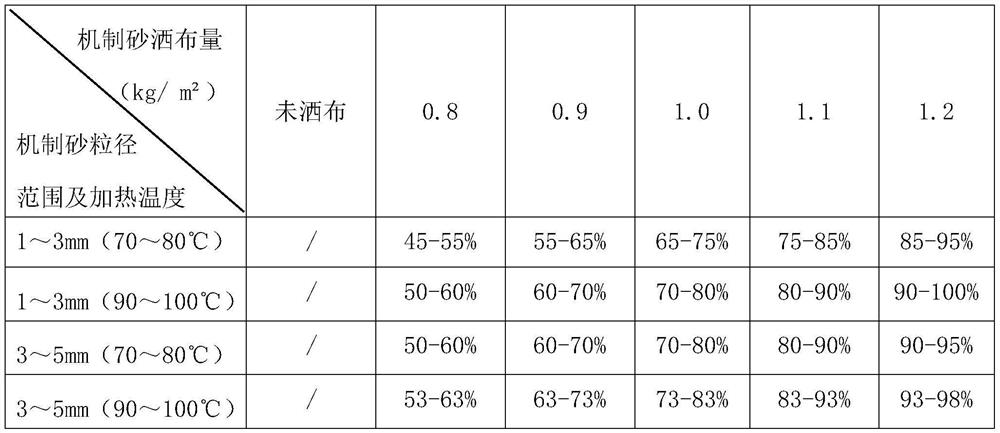

[0027]Example 1

[0028]A sprinkler process for increasing the initial anti-sliding performance of SMA pavement, including the following processing steps:

[0029]S1, select the same mechanism sand as the SMA pavement structure layer, such as mechanism sand raw materials and SMA pavement structural surface layers derived from the same stone field or the same lithology, the particle size range is from 1 to 3 mm;

[0030]S2, put the mechanism sand into the asphalt blend building for dust removal and heating; the heating temperature is controlled at 70 ~ 80 ° C;

[0031]S3, the mechanism sand after step S2 is spread through the synchronous gravel spread, the spread is completed, and the surface temperature of the road surface is cooled to 60 ~ 70 ° C, the mechanism sand sprinkler is 0.8kg / m.2;

[0032]S4, after the mechanism sand cloth is completed, the tire pressure road is used to crush the SMA road;

[0033]After the rolling is completed, the SMA pavement remaining mechanism sand is cleared using a...

Example Embodiment

[0036]Example 2

[0037]A sprinkler process for increasing the initial anti-sliding performance of SMA pavement, including the following processing steps:

[0038]S1, select the same mechanism sand as the SMA pavement structure layer, such as mechanism sand raw materials and SMA pavement structural surface layers derived from the same stone field or the same lithology, the particle size range is from 1 to 3 mm;

[0039]S2, put the mechanism sand into the asphalt blend building for dust removal and heating; the heating temperature is controlled at 70 ~ 80 ° C;

[0040]S3, the mechanism sand after step S2 is spread through the synchronous gravel spread, the spread of the SMA road surface is completed and the surface temperature is cooled to 60 ~ 70 ° C, the mechanism sand sprinkler is 0.9kg / m2;

[0041]S4, after the mechanism sand cloth is completed, the tire pressure road is used to crush the SMA road;

[0042]After the rolling is completed, the SMA pavement remaining mechanism sand is cleared using...

Example Embodiment

[0045]Example 3

[0046]A sprinkler process for increasing the initial anti-sliding performance of SMA pavement, including the following processing steps:

[0047]S1, select the same mechanism sand as the SMA pavement structure layer, such as mechanism sand raw materials and SMA pavement structural surface layers derived from the same stone field or the same lithology, the particle size range is from 1 to 3 mm;

[0048]S2, put the mechanism sand into the asphalt blend building for dust removal and heating; the heating temperature is controlled at 70 ~ 80 ° C;

[0049]S3, the mechanism sand after step S2 is spread through the synchronous gravel spread, the spread of the SMA road surface is completed and the surface temperature is cooled to 60 ~ 70 ° C, the mechanism sand sprinkler is 1.0kg / m2;

[0050]S4, after the mechanism sand cloth is completed, the tire pressure road is used to crush the SMA road;

[0051]After the rolling is completed, the SMA pavement remaining mechanism sand is cleared using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com