Boiler combustion optimization method and system based on air/pulverized coal and CO online monitoring

A boiler combustion and optimization method technology, which is applied in the direction of combustion method, combustion control, air supply adjustment, etc., can solve the problem of single adjustment means and can not reflect the combustion situation in the furnace well, and achieve clear adjustment goals and control Various ways to expand the effect of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

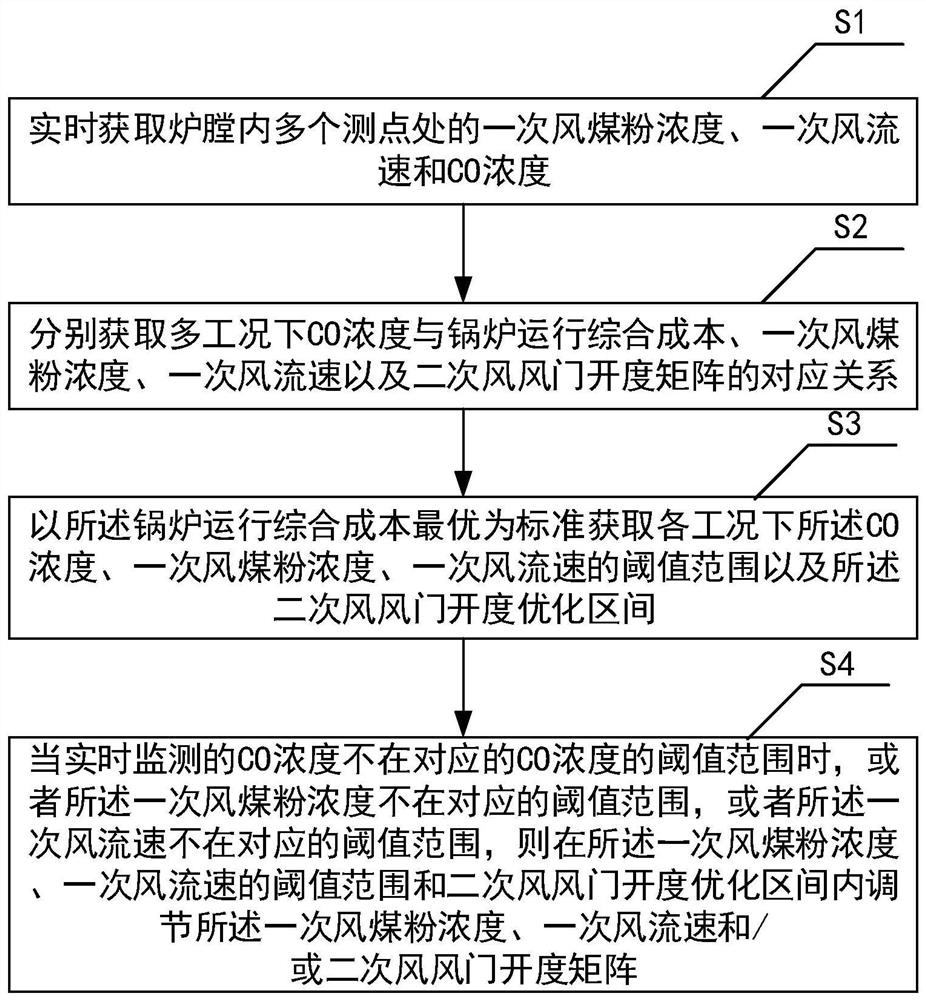

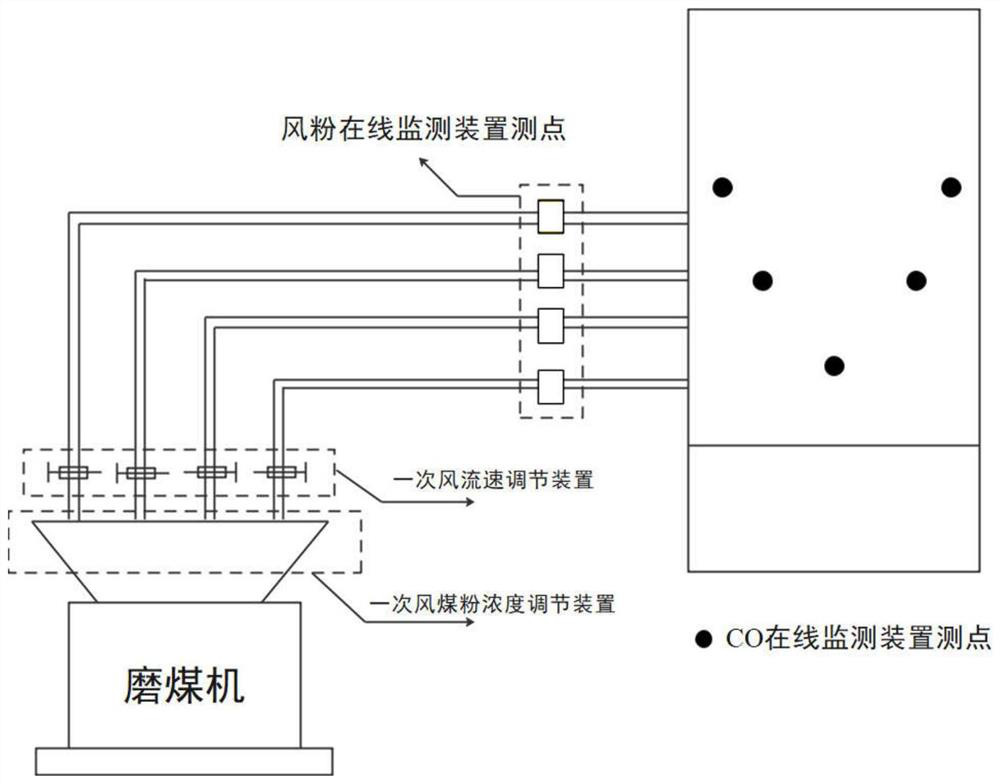

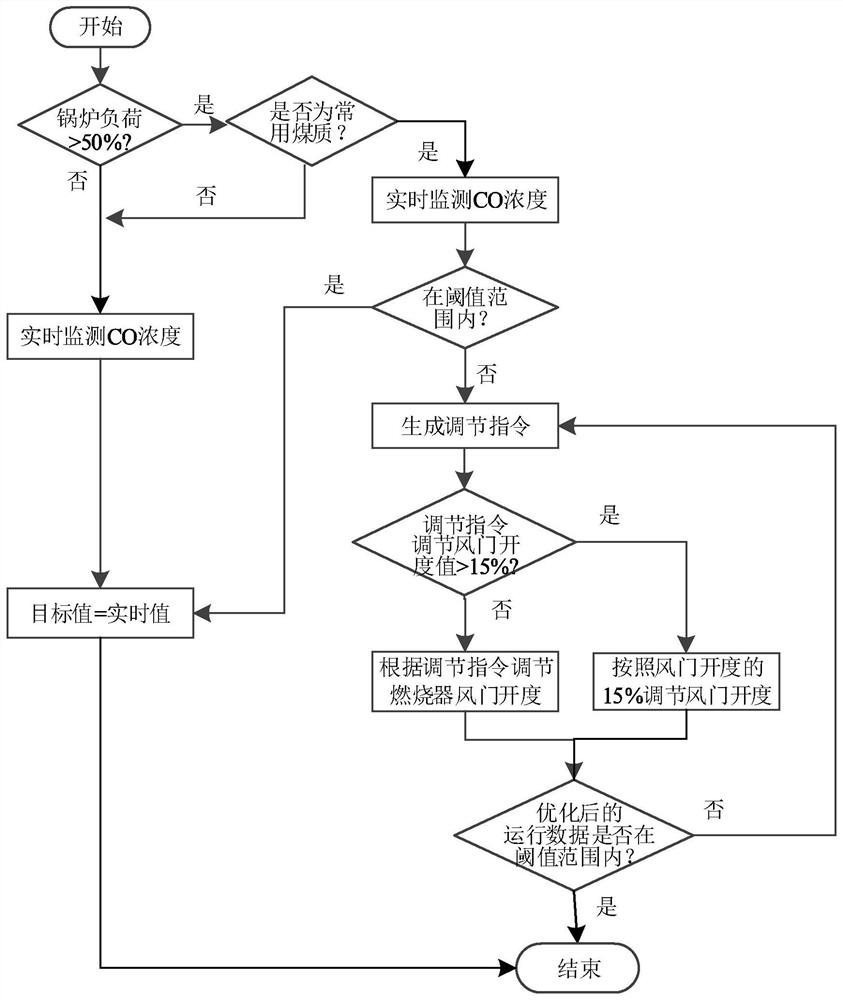

[0030] see figure 1 and image 3 , the present invention provides a boiler combustion optimization method based on air powder and CO online monitoring, the method includes steps S1-S4.

[0031] The present invention takes a 600MW unit in a certain power plant as an example to elaborate. The boiler is a π-type front and rear wall-contrasting boiler equipped with 6 coal mills, and one coal mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com