Contact lens edge defect detection method

A contact lens and detection method technology, which is applied in the field of biomedical engineering, can solve problems such as difficult image processing, turning edges, and slow calculation speed, and achieve the effects of accurate defect judgment, guaranteed product quality, and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

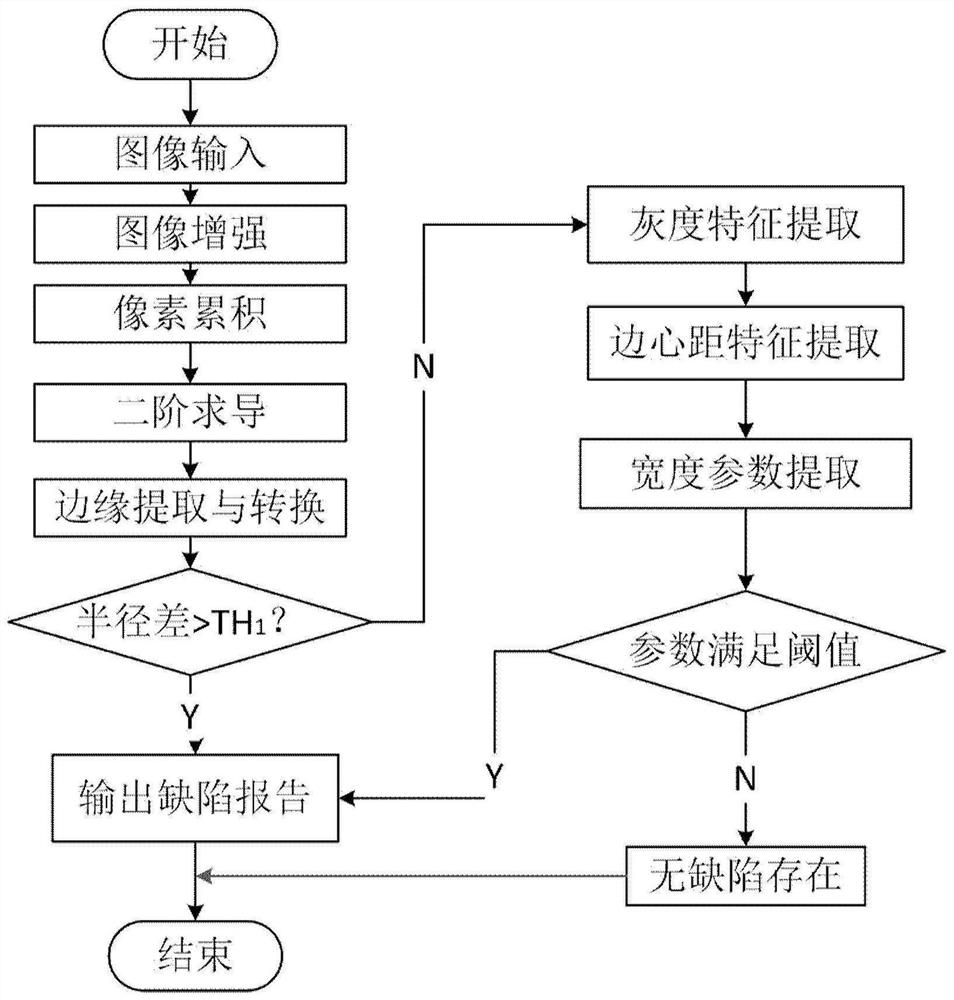

Method used

Image

Examples

Embodiment 1

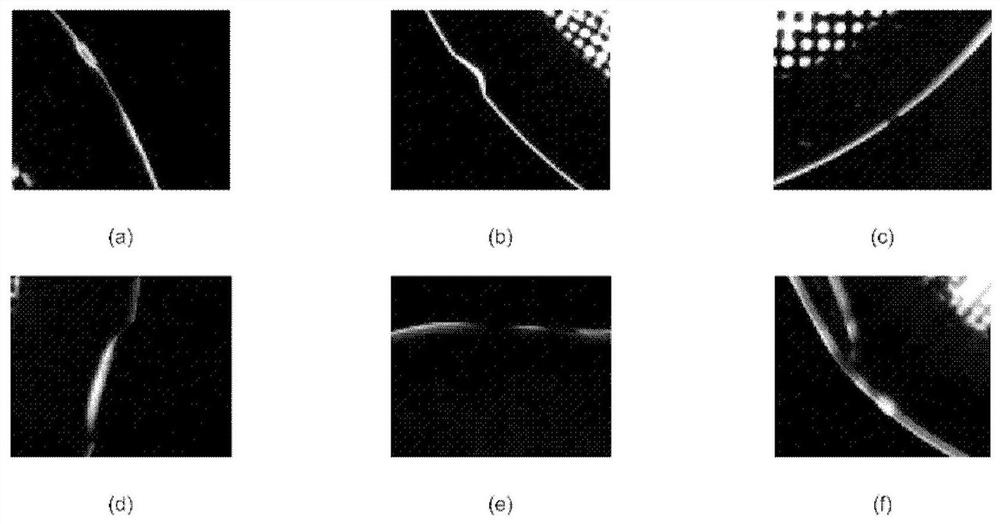

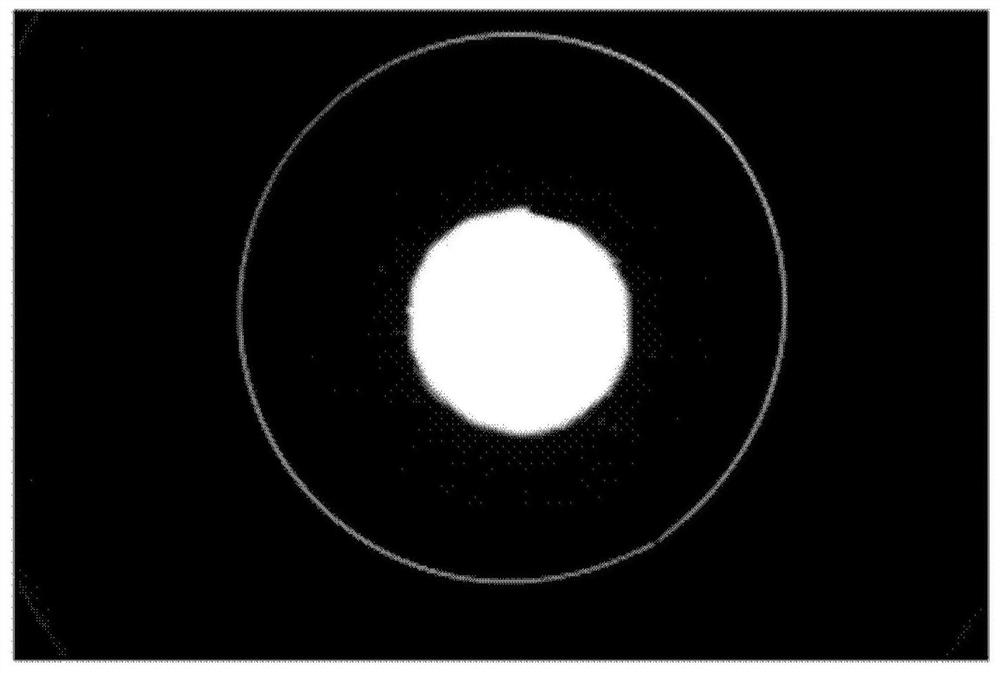

[0096] In this embodiment, 307 pictures with normal edges are selected for feature extraction. The preprocessing is image classification contrast enhancement and median filtering. The threshold shown in Table 1 is set according to the parameter range, and the upper limit of DR is 20 pixels; the gray level change feature contains three parameters, namely GPM, GPMW, and GPMD, and the GPM limit is 100, and GPMW only makes statistics For the threshold setting, refer to the extraction of defect pictures, GPMD is set to 80; DSR is normal within 2; the upper limit of DEM is 1; the edge width WR should be between 0.5-1.5 times the average width; the upper limit of the edge width change slope WM is 1.

[0097] Table 1 Threshold range of edge features

[0098]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com