Heat transter tube with cross-groove and method of manufacturing same thereof

A manufacturing method, technology of heat transfer tubes, applied in the direction of tubular elements, metal rolling, heat exchange equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

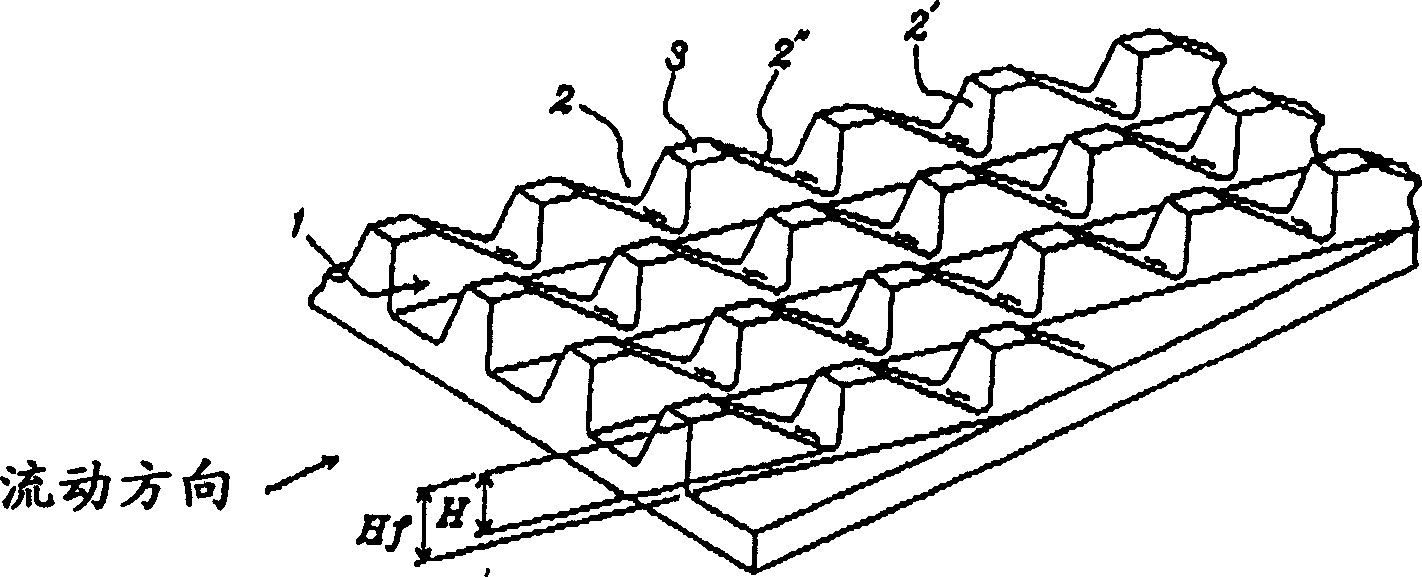

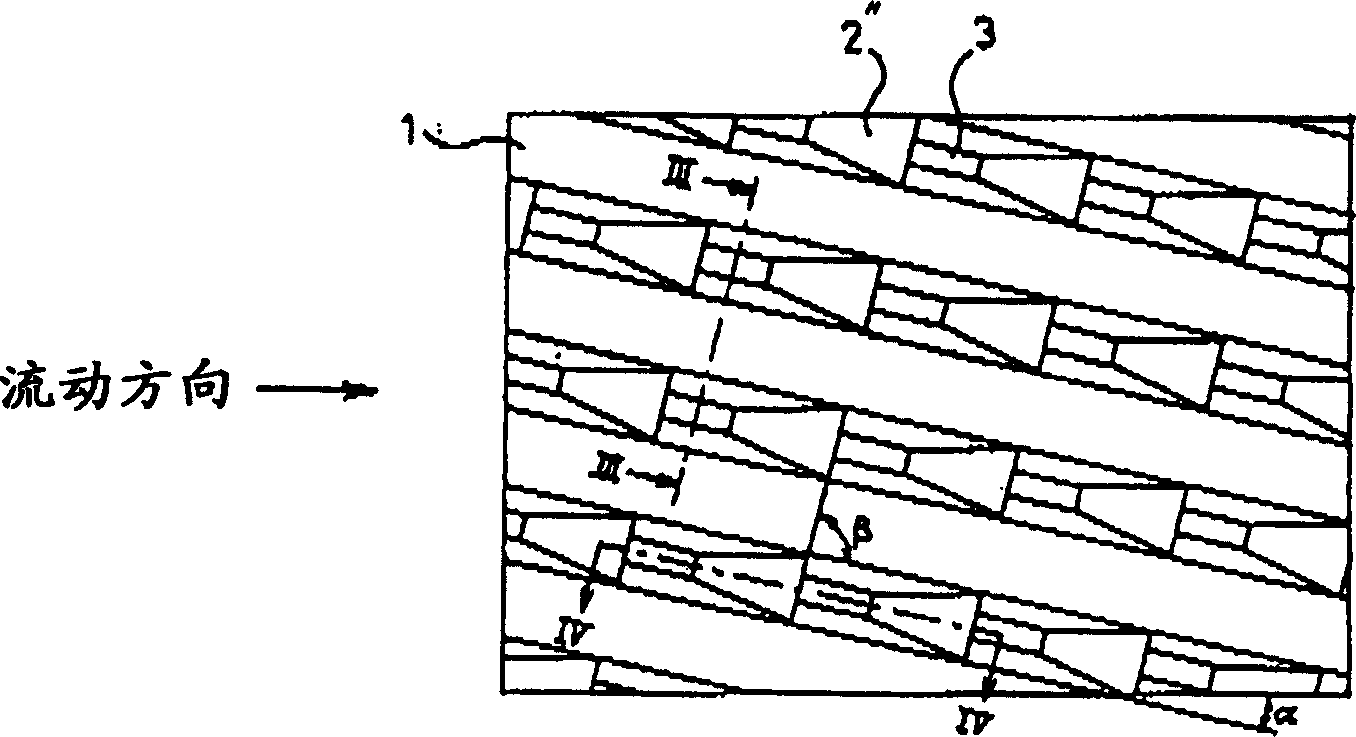

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

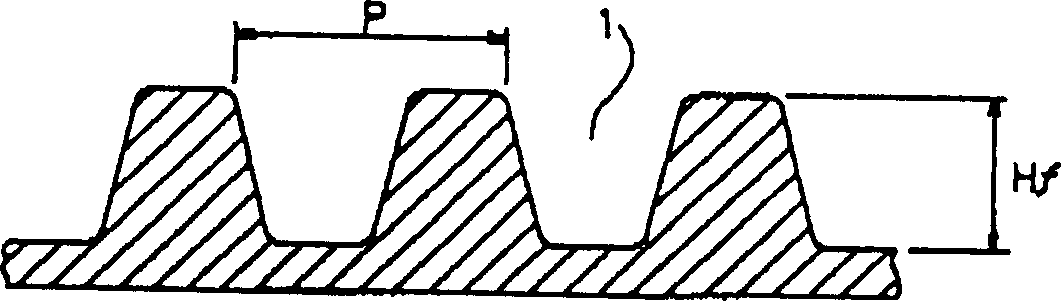

[0028] The heat transfer tube with intersecting grooves of the present invention is a metal tube with a circular cross section, and a plurality of helical grooves 1 are formed on the entire inner surface of the tube. These helical grooves 1 are parallel to each other and form a certain helical angle relative to the longitudinal axis of the tube. alpha. Such as image 3 As shown, the cross-sectional shape of the helical groove 1 is an inverted trapezoid. In addition, the above-mentioned heat transfer tube with intersecting grooves is also equipped with a plurality of auxiliary grooves 2, and these auxiliary grooves 2 are parallel to each other and intersect with the helical groove 1 at a certain angle β. Such as Figure 4 As shown, the cross-sectional shape of the auxiliary groove is basically a right triangle, and has a helix angle larger than that of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com