Reinforced fiber tape material and production method therefor, fiber reinforced resin molded body and reinforced fiber layered body using reinforced fiber tape material

A technology for reinforcing fibers and manufacturing methods, which is applied to chemical instruments and methods, synthetic resin layered products, coatings, etc., and can solve the problems of high manufacturing costs, residual end materials, and a large amount of reinforced fiber waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

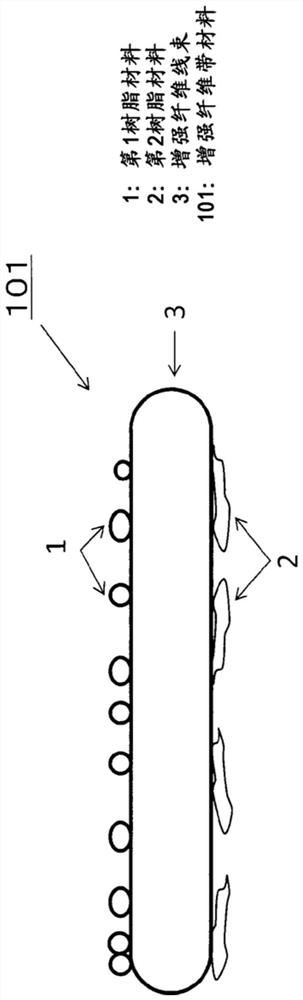

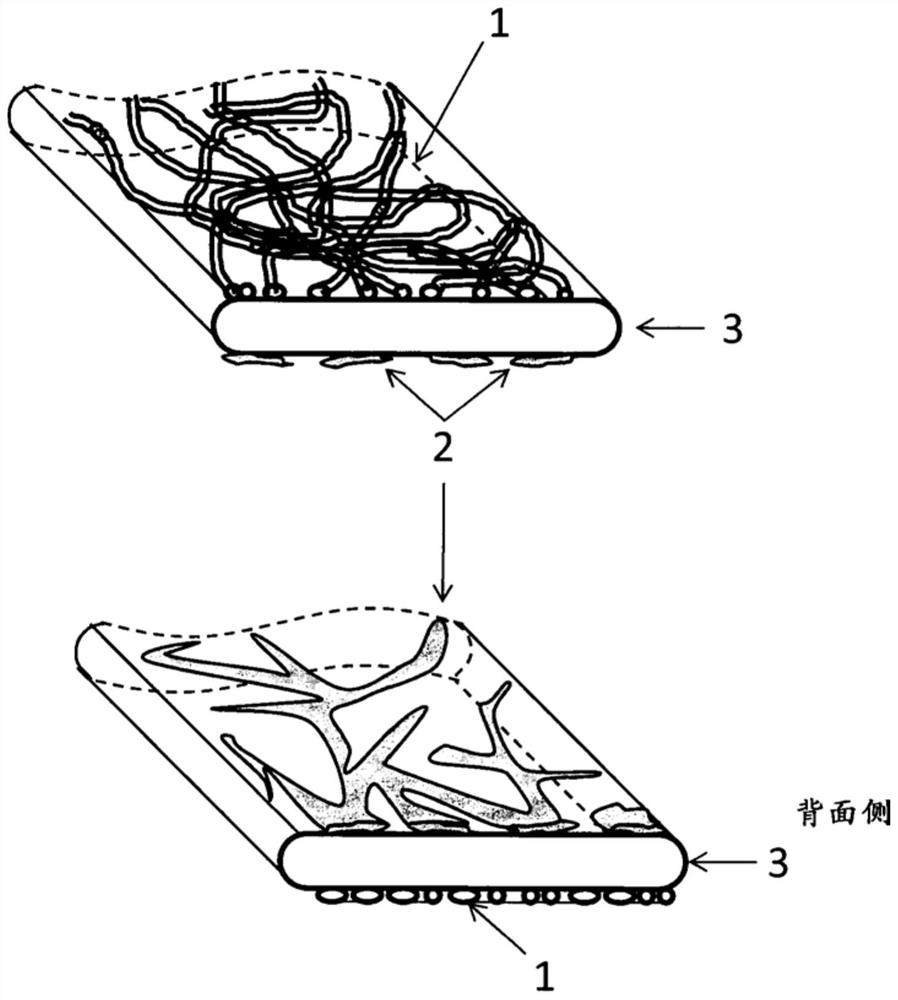

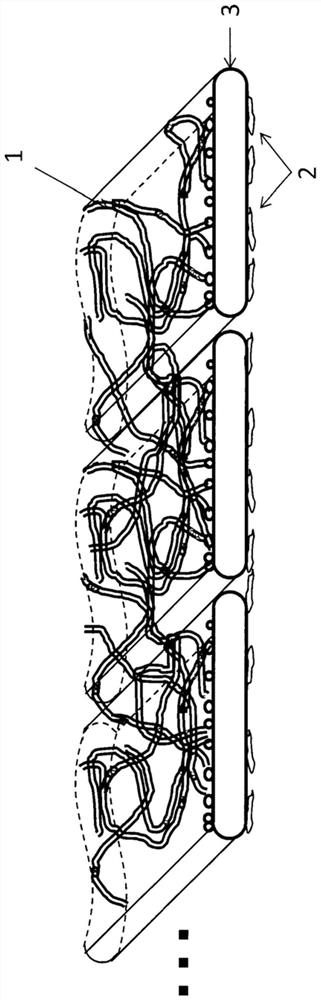

[0150] Using a reinforcing fiber tape material manufacturing device, for one carbon fiber wire bundle pulled out from a bobbin while adjusting the width to 4.0mm width, such as Figure 10 As shown, a non-woven fabric (made of polyamide resin, melting point 190° C.) is put in as the first resin material 1 from one side, and a non-woven fabric (made of polyamide resin, melting point 95° C.) is put in from the other side as the second resin material 2. ℃), while arranging to sandwich the carbon fiber bundle, let it pass through the heating part 12 heated to 180 ℃ and the pressing part 13 (nip roll, pressing force: 0.1MPa), then cool to 40 ℃ or less and Winding is performed to obtain a reinforcing fiber tape material in which a nonwoven fabric and a carbon fiber harness are integrated.

[0151] Manually cut out a reinforcing fiber tape material of about 500 mm in length from the wound bobbin again, placed it on a flat plate, and carried out surface observation and width measuremen...

Embodiment 2

[0154] Using a reinforcing fiber tape material manufacturing device, 6 carbon fiber strands pulled out from the bobbin while adjusting the width to 4.0 mm in width are pulled out while paralleling each other with a gap of 0.3 mm. In addition, The same operation as in Example 1 was carried out to obtain a reinforcing fiber tape material in which a nonwoven fabric and a plurality of carbon fiber strands were integrated. Surface observation after winding, width measurement, and a test of pressing against a flat plate with a roller at room temperature and 80° C. resulted in the same results as in Example 1.

Embodiment 3

[0185]

[0186] As the reinforcing fiber bundle, Toray Co., Ltd.-manufactured reinforcing fiber "Torayca" (registered trademark) T800SC subjected to sizing treatment in advance was used, and the number of reinforcing fiber filaments was 24,000 (N=24K).

[0187]

[0188] Using a reinforcing fiber tape material manufacturing device, a reinforcing fiber bundle with a width of W' = 8 mm and a number of filaments N [K] = 24 (N / W = 3) is pulled out from a bobbin, and the width is narrowed without dividing while adjusting the thickness. Cut to obtain a bundle of carbon fiber strands with a width of W=4.0mm (the number of filaments N=24[K], N / W=6, the thickness T1=332 μm at the end, the thickness T2=293 μm at the center, and the other end Thickness T3 = 320 μm, the ratio of the thickness of the end portion and the central portion T1 / T2 = 113% and T3 / T2 = 109%). Then, heat-melting resin particles (average particle diameter: 0.2 mm) having a softening point of 80° C. were scattered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com