Die

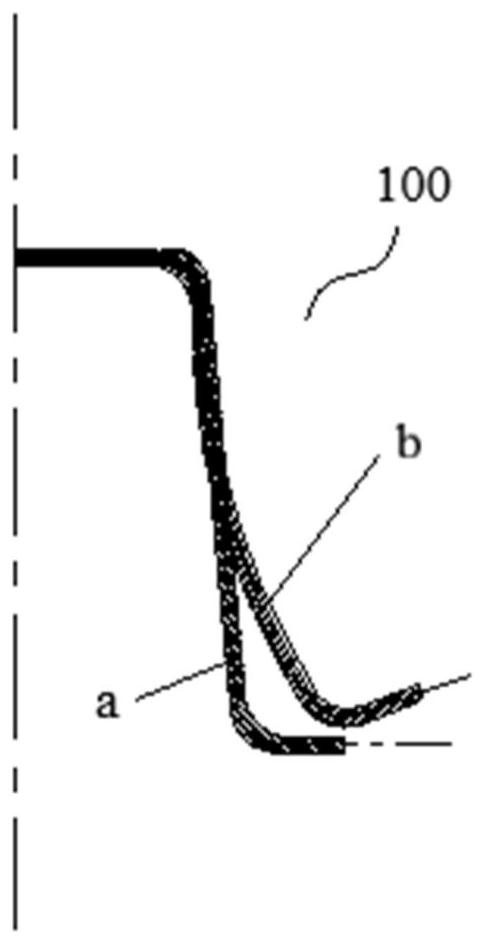

A mold and punch technology, applied in the field of machining, can solve the problems of easy wear of the blank holder, easy jamming of the drawbead and blank holder, and achieve the effects of increasing resistance, sufficient plastic deformation, and not easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

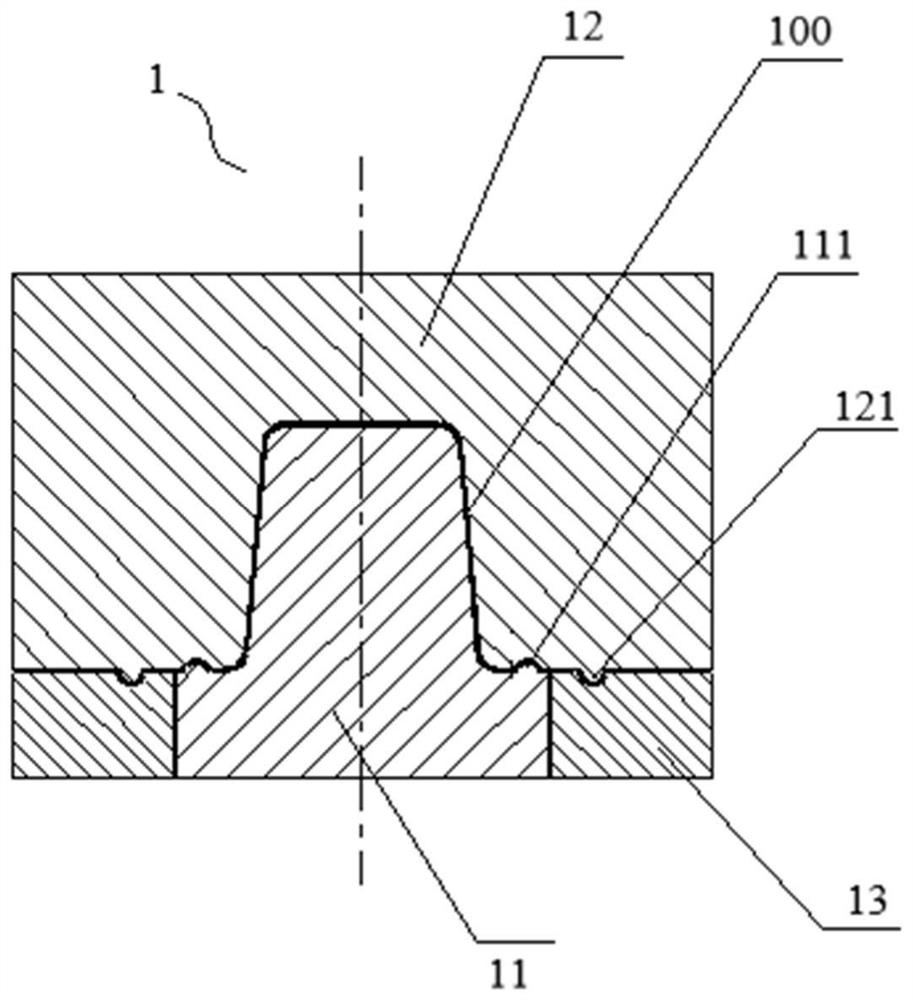

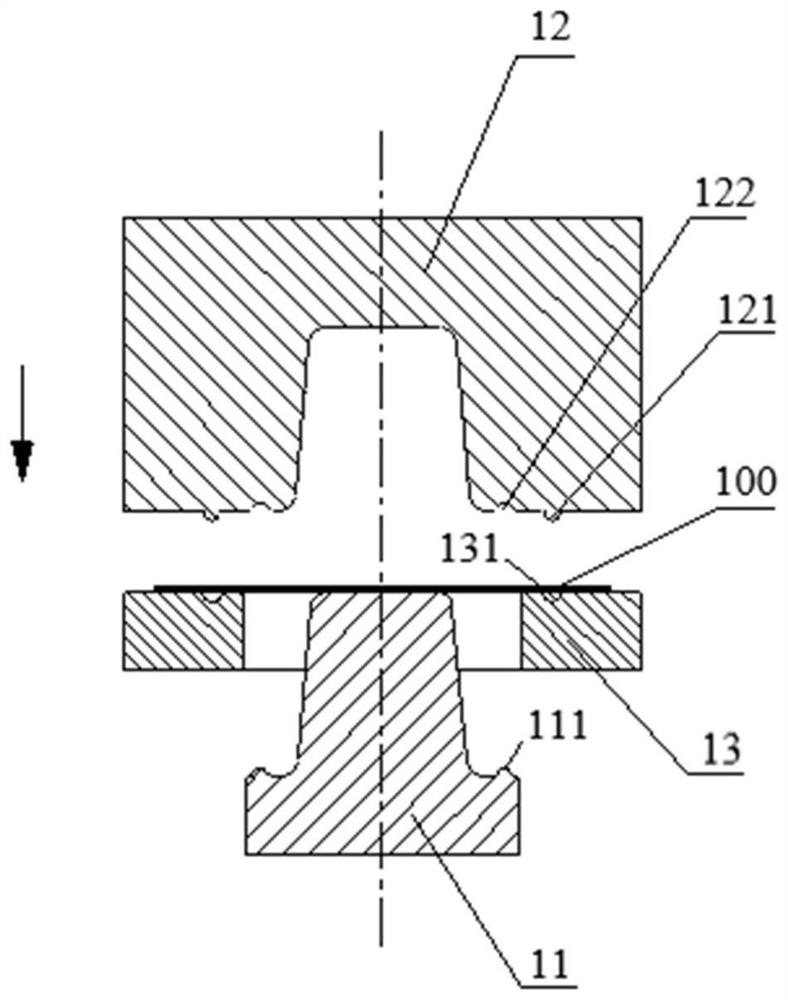

[0043] figure 2 It is a partial structural sectional view of a mold in the embodiment of the present application, such as figure 2 As shown, the embodiment of the present application provides a mold 1, including a punch 11, a die 12 and a blank holder 13, wherein the blank holder 13 is sleeved on the punch 11 to support the workpiece together with the punch 11 100. The concave mold 12 is used for concave-convex cooperation with the convex mold 11 to stamp the workpiece 100 .

[0044] refer to image 3 , in the above-mentioned mold 1, among the blank holder 13 and the die 12, one is provided with a first groove 131, and the other is fixedly provided with a first drawbead 121, and the first drawbead 121 and the first recess The groove 131 cooperates with the workpiece 100 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com