Device and construction process suitable for on-site rapid cold drawing and straightening of thick reinforcing steel bars

A construction technology and straightening technology, which is applied in the field of building construction, can solve problems such as inability to straighten steel bars, inconvenient on-site operation, and high safety risks, and achieve the effects of reasonable construction technology design, improved work efficiency, and guaranteed straightening quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

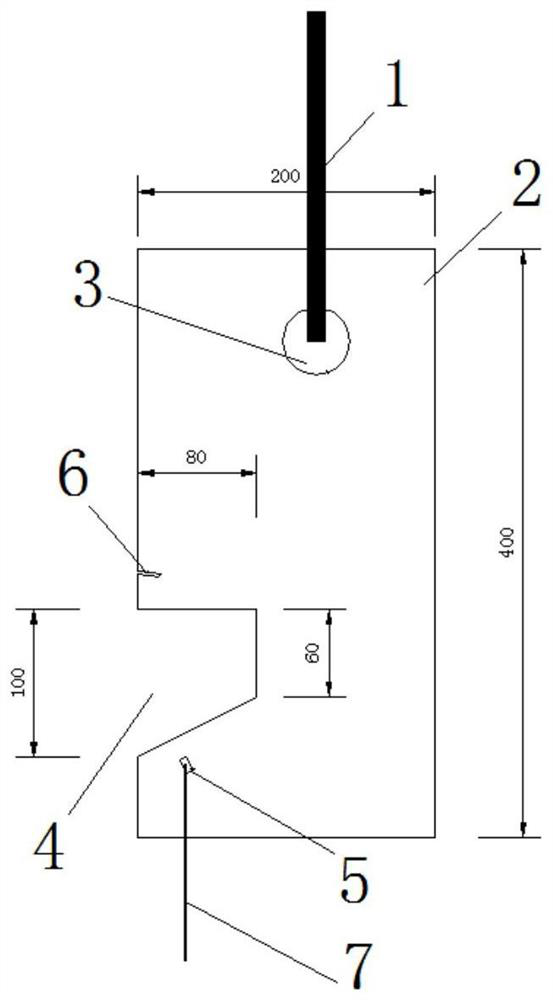

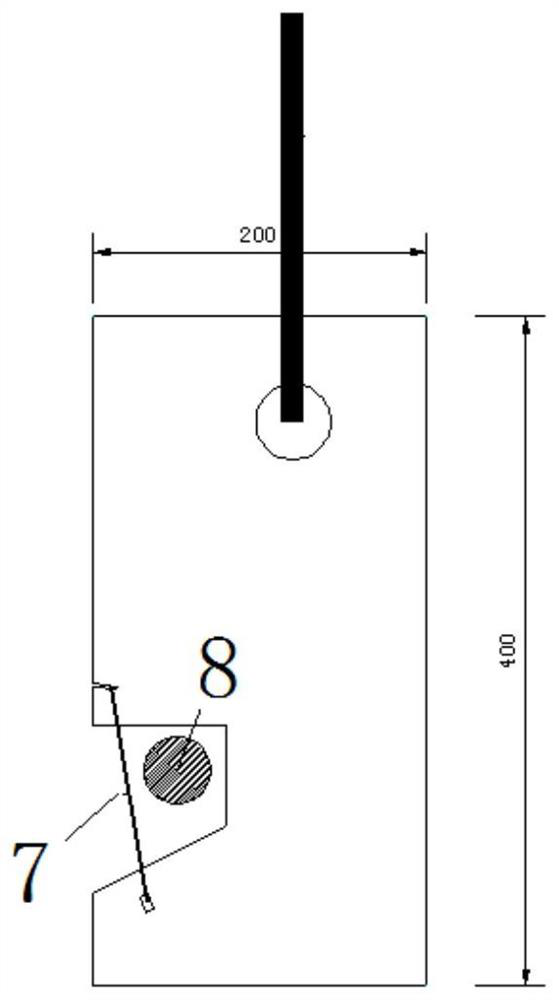

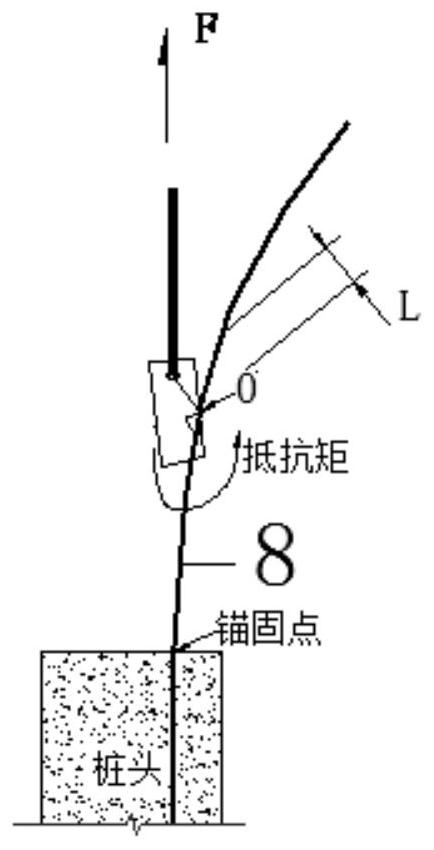

[0033] like Figure 1 to Figure 3 As shown, the device suitable for rapid cold-drawing and straightening of thick steel bars on site includes a straightening steel plate. The upper part of the straightening steel plate is provided with a lifting hole for connecting with a steel wire rope, and one side of the straightening steel plate is provided with a Straightening notch into which the straight bar snaps.

[0034] The straightening steel plate is a rectangular steel plate, and the lifting hole is set on the upper end of the steel plate; the straightening notch is a trapezoidal notch, and compared with other notches, the steel bar to be straightened will be in the notch when the stress concentration is severe. Adaptive slight sliding, no damage to the steel bars. The right-angle part of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com