Rotary screen printing machine

A technology of rotary screen printing and printing machines, which is applied to screen printing machines, printing machines, rotary printing machines, etc. It can solve the problems of poor stability, high cost, and long cycle, so as to improve anti-deformation ability, reduce construction difficulty, The effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

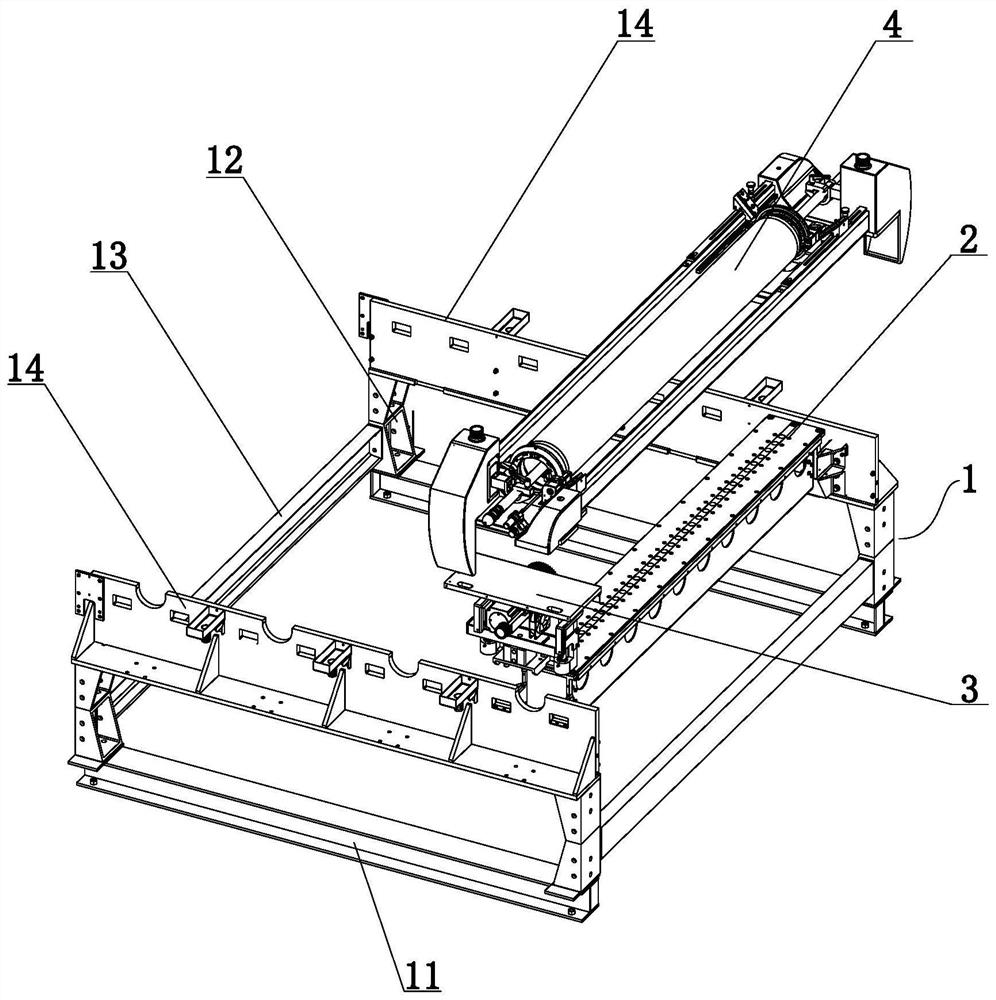

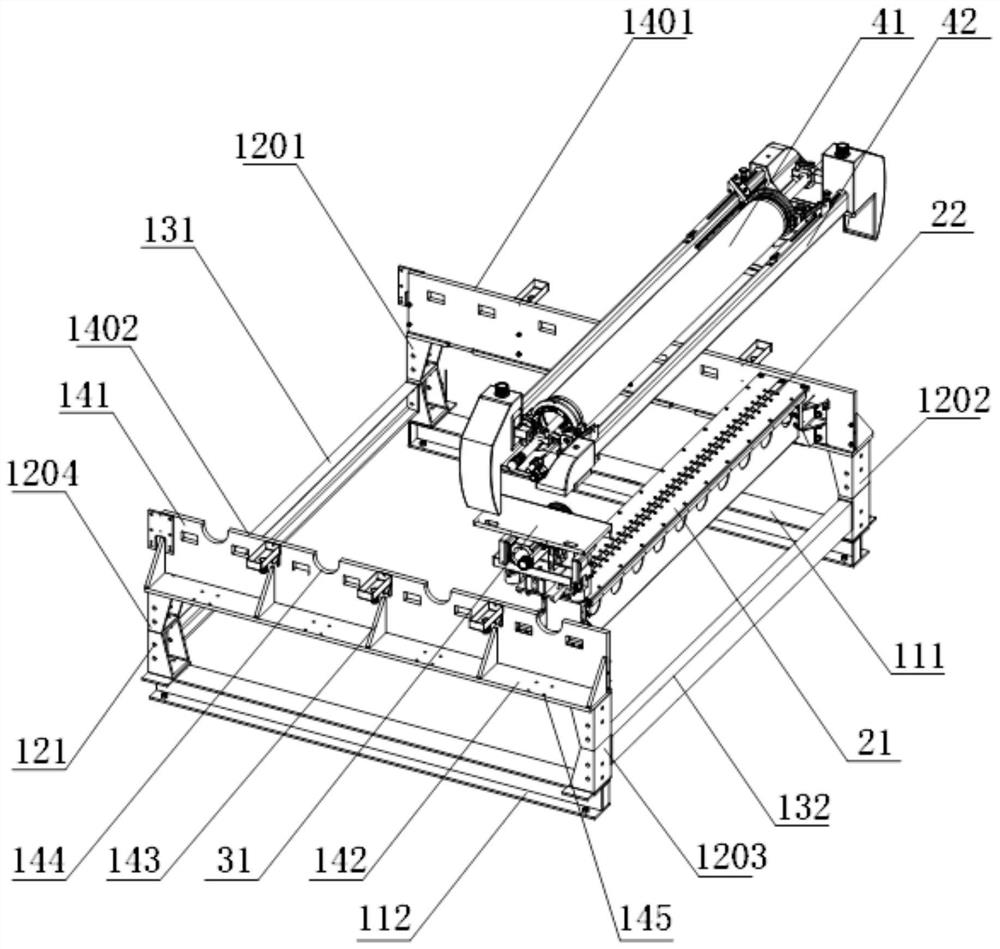

[0038] Such as figure 1 and figure 2 As shown, the guide belt (not shown) is arranged on the top of the frame 1, and the frame 1 includes a base plate 11, a support column 12, a beam 13 and a top plate 14; The top and the bottom end are respectively provided with screw holes (not shown in the figure), the base plate 11 comprises a first base plate 111 and a second base plate 112, and the support column 12 is arranged on the top of the base plate 11 both sides, and the support column 12 is formed by two trapezoidal columns. The special-shaped supporting column of non-closed structure is formed by splicing. The splicing part is connected and fixed by welding. The top, bottom and side of the supporting column 12 are all provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap