Seawater coral aggregate concrete for emergency repair and construction engineering and preparation method thereof

A concrete and seawater technology, which is applied in the field of seawater coral aggregate concrete and its preparation, can solve the problems of high transportation cost, high dependence on land transportation building materials, and long transportation cycle of land transportation building materials, so as to reduce the reserve and solve the problem of dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

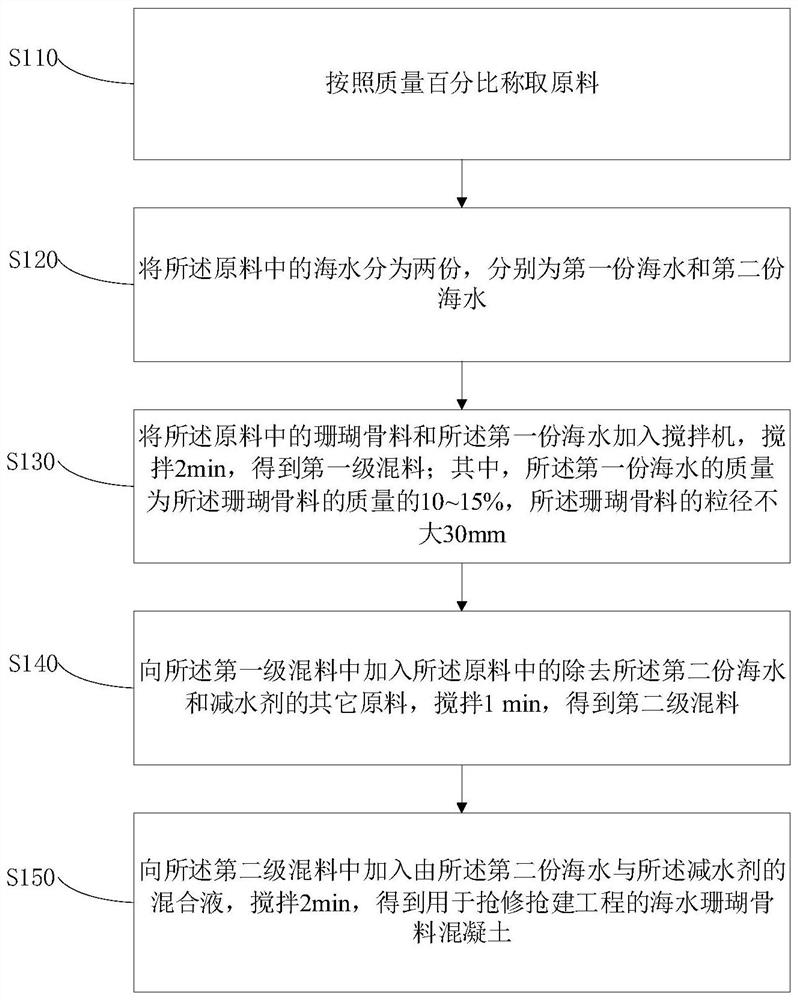

[0047] like figure 1 As shown in the figure, the preparation method of seawater coral aggregate concrete for emergency repair and emergency construction provided by the present invention is applied to the cast-in-place construction process or prefabrication process of seawater coral aggregate concrete for emergency repair and emergency construction. The method includes the following steps:

[0048] S110, weighing raw materials according to mass percentage;

[0049] S120, dividing the seawater in the raw material into two parts, namely the first part of seawater and the second part of seawater;

[0050] S130, adding the coral aggregate in the raw material and the first part of seawater into a mixer, and stirring for 2 minutes to obtain a first-grade mixture; wherein, the quality of the first part of seawater is 10-15% of the quality of the coral aggregate, and the The particle size is less than 30mm;

[0051] S140, add the other raw materials in the raw material that remove ...

Embodiment 1

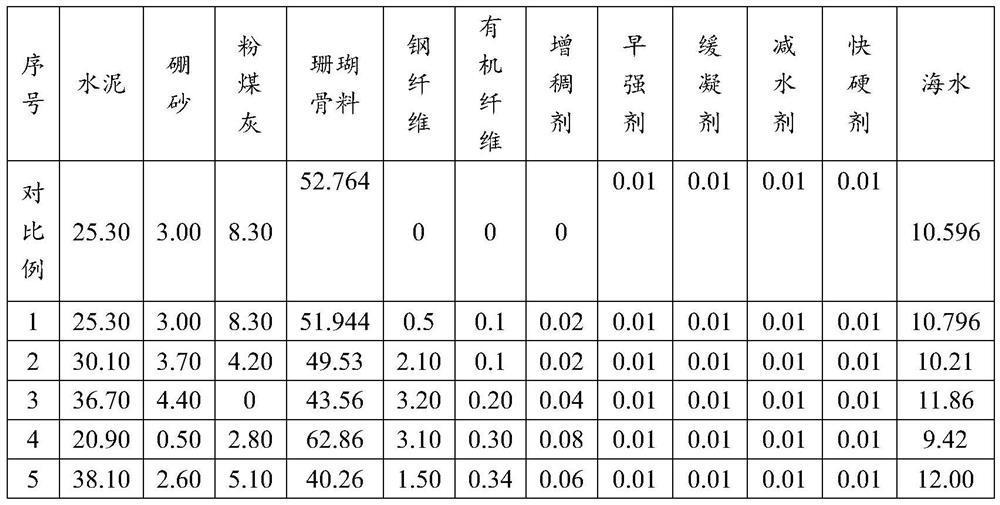

[0064] The raw material percentage of seawater coral aggregate concrete used in emergency repair and construction projects is shown in Table 1. Among them, the cement is magnesium phosphate cement.

[0065]

[0066] Table 1

[0067] The comparative examples in Table 1 were prepared by conventional concrete preparation methods;

[0068] The seawater coral aggregate concrete formulations used in the rush repair and rush construction projects in each embodiment are prepared by the following methods, including the following steps:

[0069] Weigh the raw materials according to the mass percentage;

[0070] The seawater in the raw material is divided into two parts, namely the first part of seawater and the second part of seawater;

[0071] The coral aggregate in the raw material and the first part of seawater are added to the mixer, and stirred for 2 minutes to obtain a first-grade mixture; wherein, the quality of the first part of seawater is 10-15% of the quality of the cor...

Embodiment 2

[0080] The raw material percentage of seawater coral aggregate concrete used in emergency repair and construction projects is shown in Table 3, wherein the cement is sulfoaluminate cement.

[0081]

[0082] table 3

[0083] The seawater coral aggregate concrete formula used for emergency repair and emergency construction in the comparative example in Table 3 and Example No. 1 is prepared by the following methods, comprising the following steps:

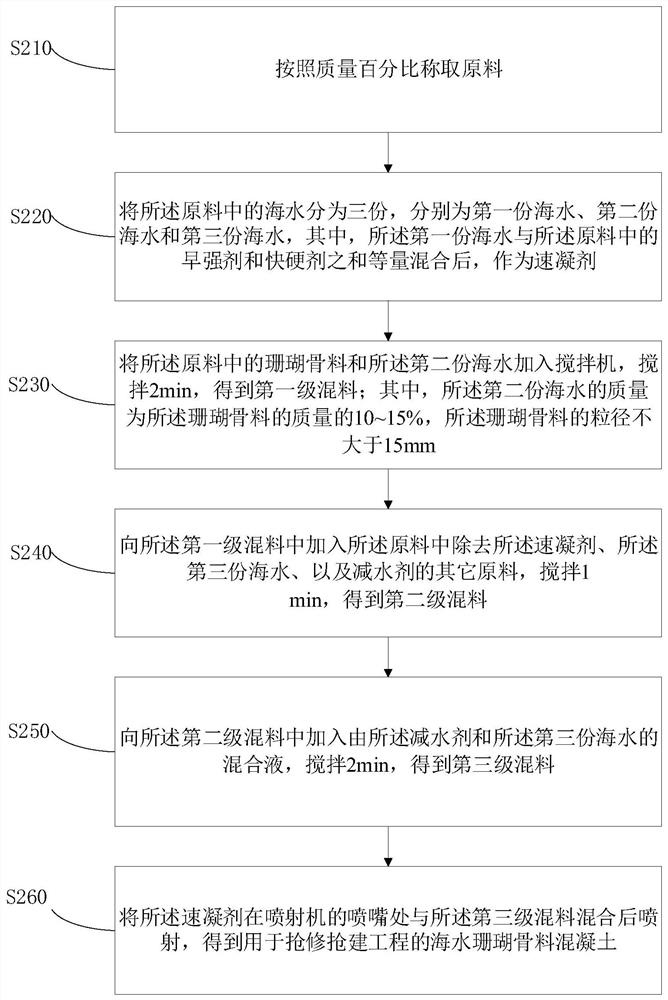

[0084] Weigh the raw materials according to the mass percentage;

[0085] The seawater in the raw material is divided into three parts, which are the first part of seawater, the second part of seawater and the third part of seawater. , as an accelerator;

[0086] The coral aggregate in the raw material and the second part of seawater are added to the mixer, and stirred for 2 minutes to obtain a first-grade mixture; wherein, the quality of the second part of seawater is 10-15% of the quality of the coral aggregate, and the coral a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com