Horizontal rotatable food fermentation device

A food fermentation, horizontal technology, applied in the field of horizontal rotatable food fermentation equipment, can solve the problems of equipment without exhaust mechanism, high carbon dioxide concentration and pressure, physical discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

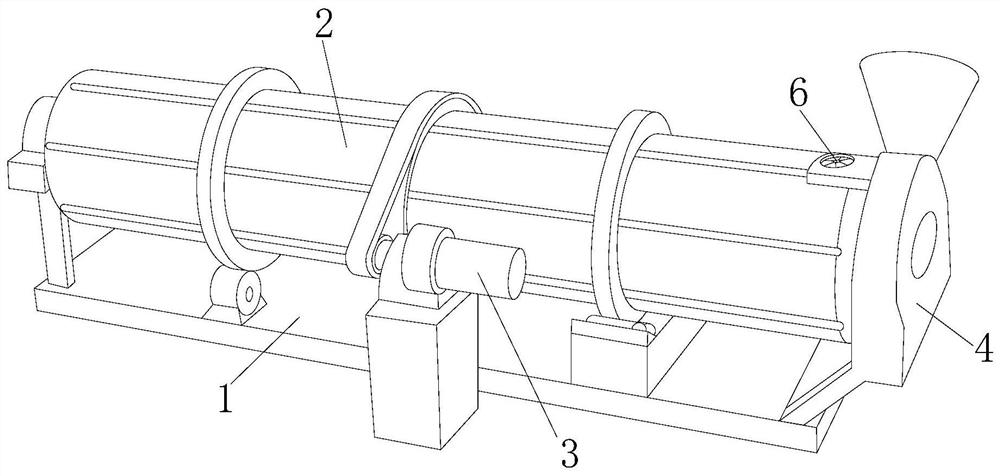

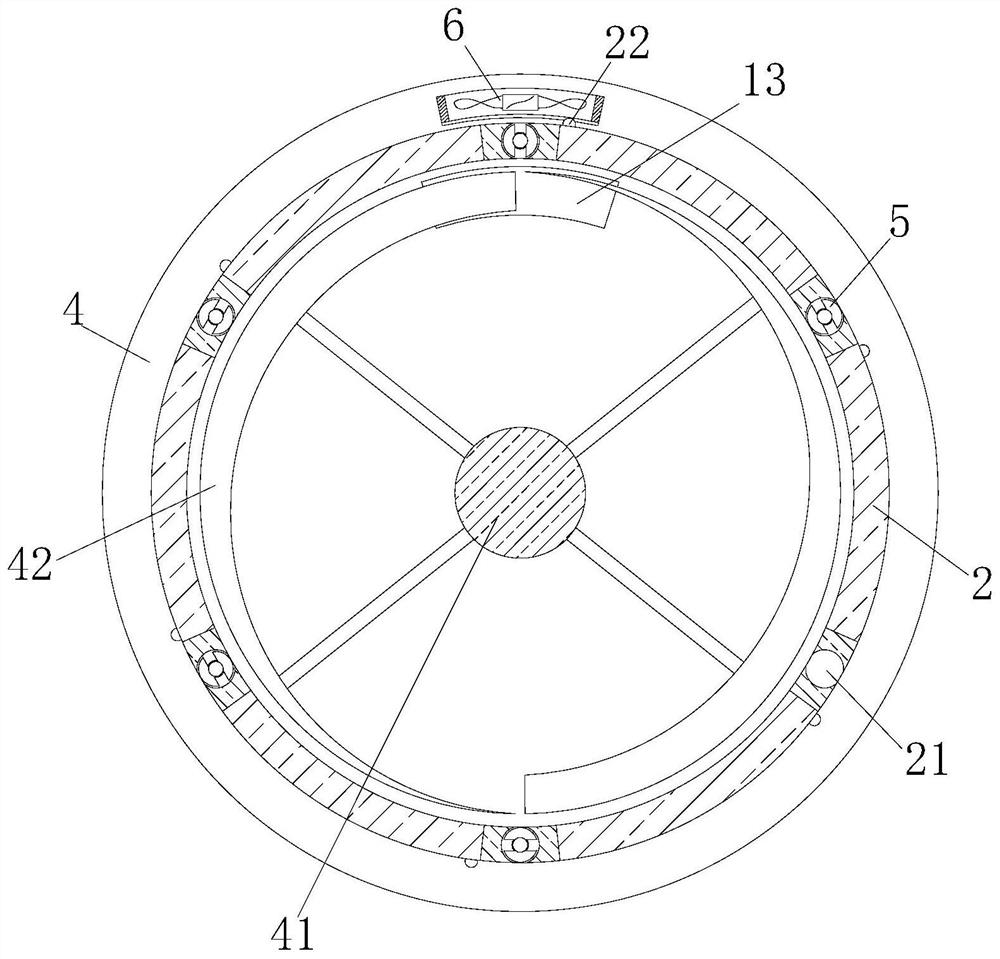

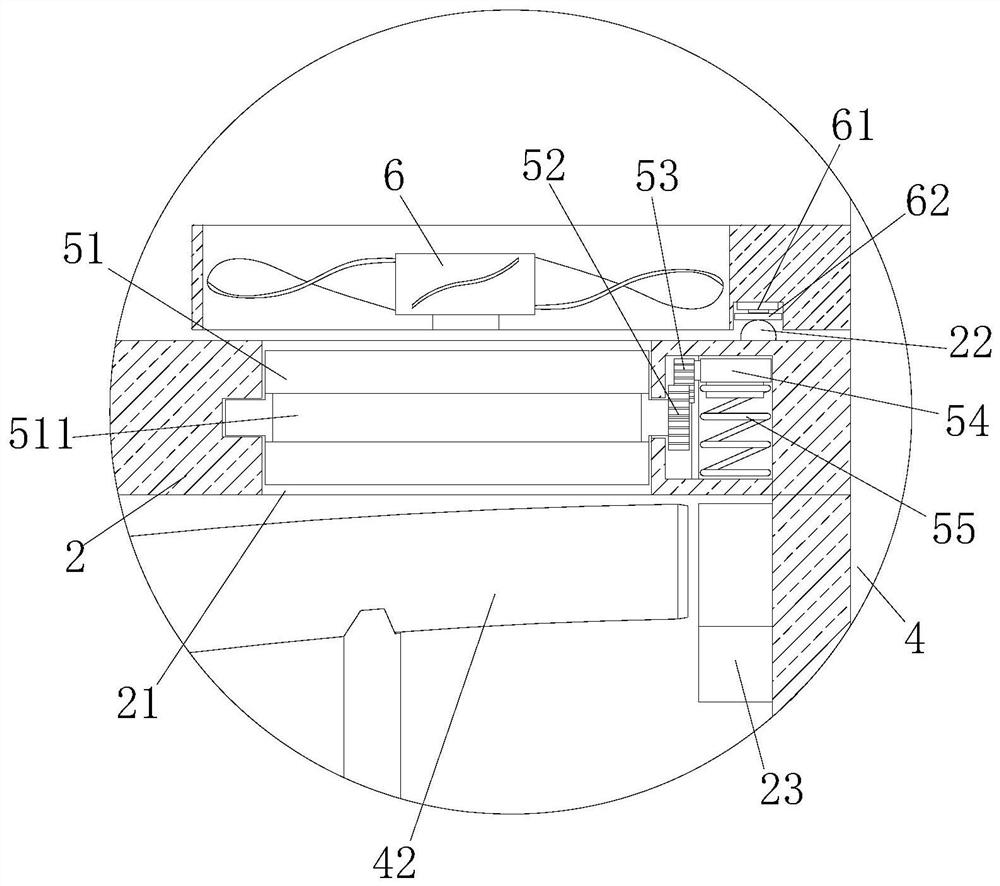

[0029] like Figure 1-Figure 7 As shown, the present invention provides a horizontal rotatable food fermentation equipment, the structure of which includes: a machine base 1, a fermenter 2, a driving machine 3, an outer shaft frame 4, a ventilating mechanism 5, and a fan 6 for helping ventilation. 2 is installed on the machine base 1, the driving machine 3 is arranged in the middle section of the machine base 1 and connected with the middle section of the fermenter 2, the fermenter 2 is inclined and the horizontal position on the right side is higher than that on the left side, the outer shaft The frame 4 is connected with the right side of the fermentation tank 2, and the outer shaft frame 4 is provided with a fixed shaft 41 and a stirring blade 42 in the fermentation tank 2, and the fixed shaft 41 is fixed on the outer shaft frame 4 and is located on the same side as the fermentation tank 2. axis, the stirring blade 42 is semicircular spiral and fixed on the fixed shaft 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com