A kind of interference fringe three-dimensional mold manufacturing method and its mold and replication method

An interference fringe and mold manufacturing technology, applied in the field of holography, can solve the problems of narrow viewing angle of holographic illusion images, difficult to meet visual requirements, unable to see recorded information, etc., to achieve a good observation experience and avoid the effect of incomplete reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] This embodiment provides a method for manufacturing a keychain interference fringe mold, comprising the following steps:

[0080] (1) Composite coherent wave sensitive materials on the surface of the three-dimensional mold by spraying method: in a clean environment, spray the required sensitive materials evenly on the original working surface with a spray gun at an appropriate concentration, appropriate distance and moving speed, and let it stand After 3-5 minutes, put it into an oven at 100°C for an appropriate time (about 1 hour), bake at 180°C for 2 hours, take it out, cool to room temperature, and set aside. This method is suitable for more complicated coating of sensitive materials on the original working surface.

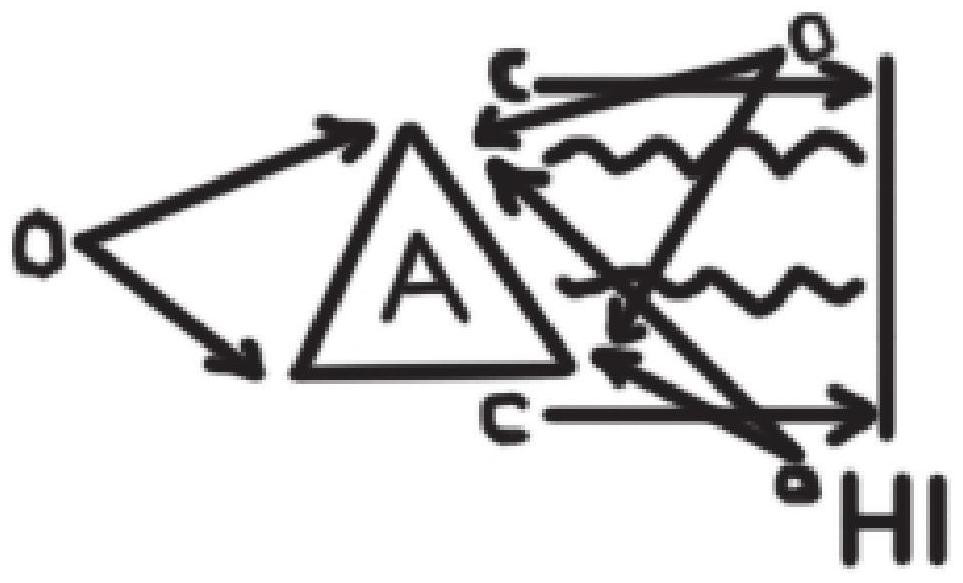

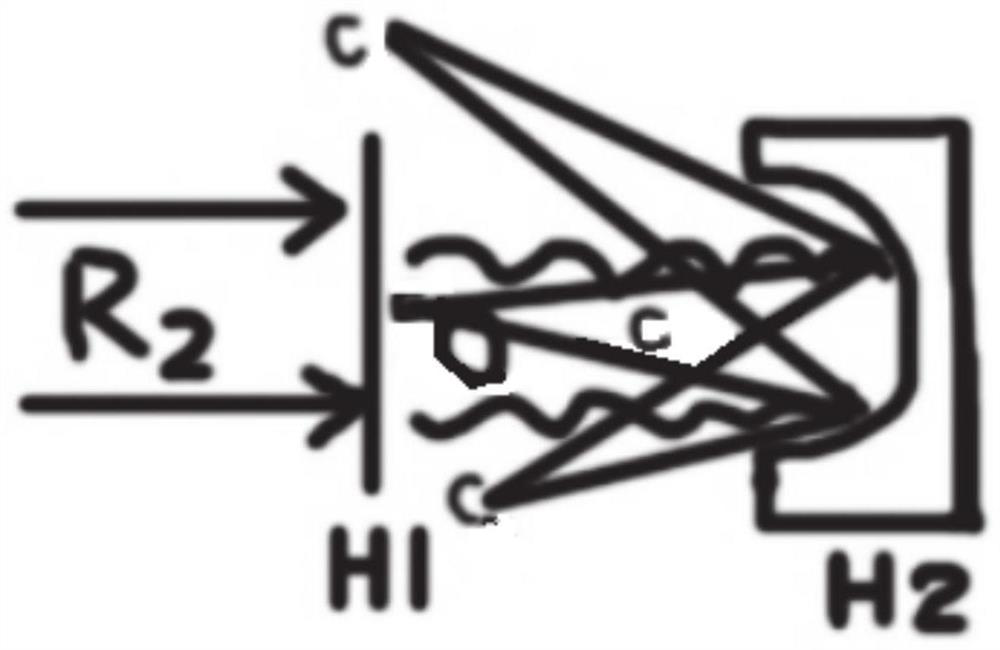

[0081] (2) Through the three-dimensional space optical path setting, the interference fringes are recorded by a two-step method, so that the interference fringes meeting the requirements are obtained on the coherent wave sensitive material layer on the ...

Embodiment 2

[0091] This embodiment provides a method for manufacturing a shadow plate interference fringe mold, which includes the following steps:

[0092] (1) Composite coherent wave sensitive materials on the surface of the three-dimensional mold by pasting method: in a clean environment, wear disposable clean gloves, apply the film coated with the sensitive material on the original working surface smoothly, and remove Leave the excess at room temperature for 10-20 minutes and set aside.

[0093] (2) Record the interference fringes on the above-mentioned sensitive materials. Step is the same as embodiment 1 step (2).

[0094] (3) Obtain the shadow plate interference fringe mold. Step is the same as embodiment 1 step (3).

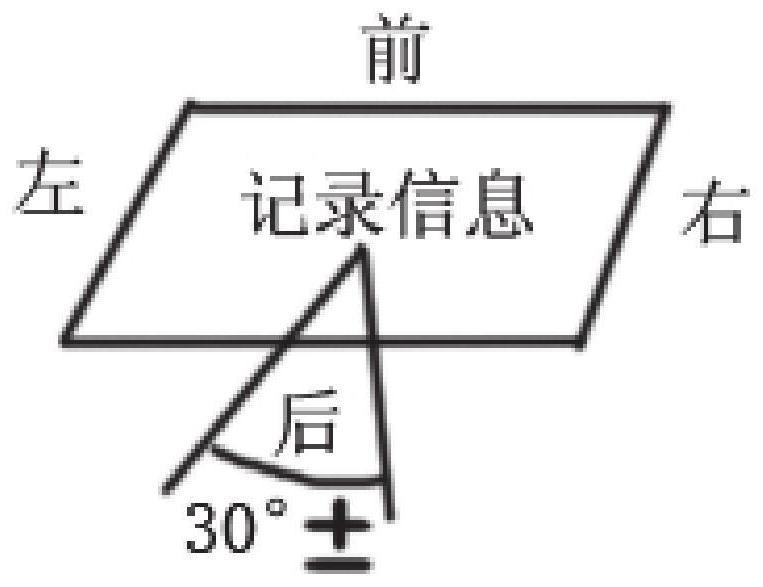

[0095] The interference fringe molds provided by one or more examples shown in the present disclosure all have an observation angle of more than 65° and more than four observation directions (that is, the recording content can be observed at a large angle in multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com