Boiler automatic tube cleaning method

一种锅炉、自动的技术,应用在锅炉清洗控制装置、清洁方法和用具、化学仪器和方法等方向,能够解决普通用户很难进行等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

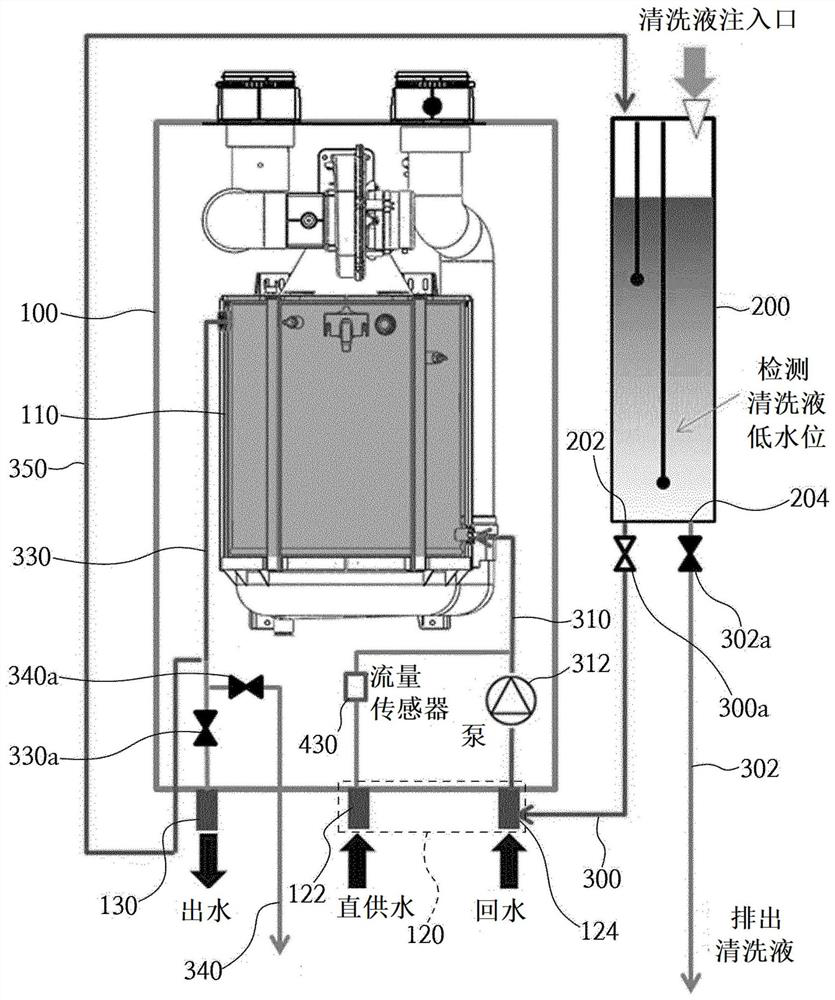

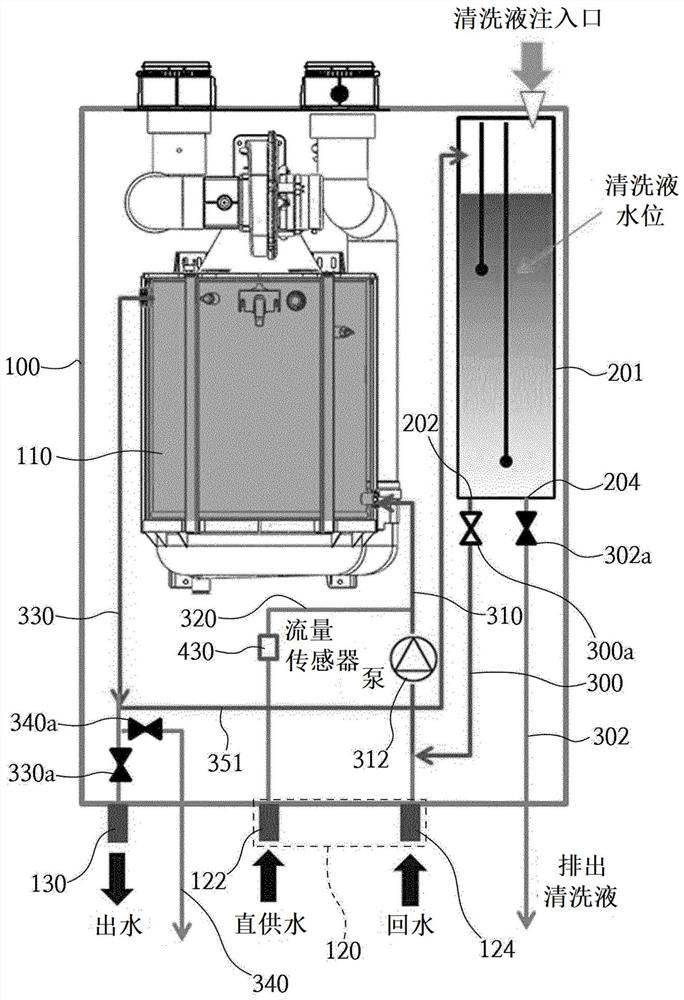

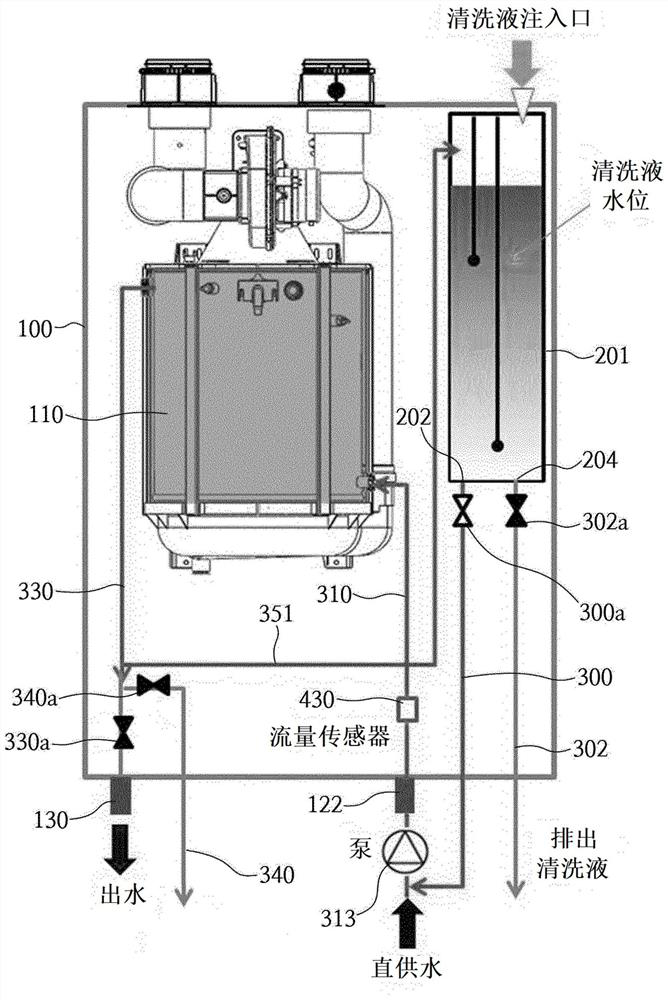

[0052] Hereinafter, the system and method for automatic boiler tube cleaning according to preferred embodiments of the present invention will be described in further detail with reference to the accompanying drawings.

[0053] figure 1 is a diagram for explaining a boiler automatic tube cleaning system according to a preferred embodiment of the present invention.

[0054] refer to figure 1 , the boiler automatic tube cleaning system according to the preferred embodiment of the present invention includes a casing 100 and a tube cleaning tank 200 .

[0055] For example, the casing 100 forms the appearance of a domestic or commercial boiler, and a space is formed inside. The lower side of the housing 100 is sequentially provided with an inflow connection part 120 and an outflow connection part 130 that function as connectors for connecting pipes. The inflow connection 120 may include a straight water supply connection 122 and a return water connection 124, such as image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com