Paddy field flat ground slurry stirring machine

A technology of agitator and leveling, which is applied in the fields of tillage machinery, agricultural machinery and machinery, and application, can solve the problems of easy replacement, loose soil damage, inconvenient use, etc., and achieves the effect of reducing the overall height and reducing the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

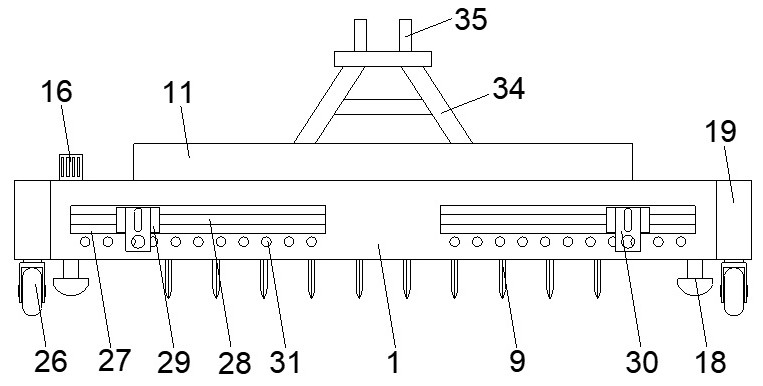

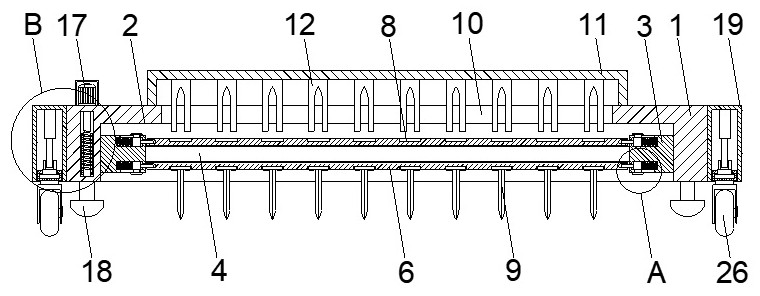

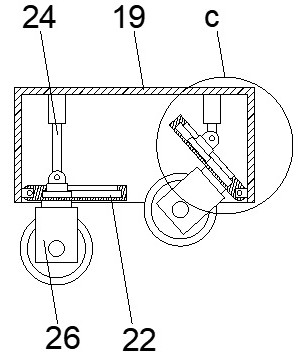

[0024] See Figures 1 to 7 According to the present invention, it provides a technical solution: a surface slurry, including a slurry outer casing 1, and inner rotating mounting groove 2 inner rotating mounting groove 2, inner rotating mounting groove 2 inner rotating mounting groove 2 The two ends are rotated and connected to the rotating column 3, and the two rotation is fixed to the mounting column 3, and the two rotation, the mounting column 3 is provided on one side of the rotating connection column 4, all of the finite mechanism 5 The two rotation of the mounting column 3 and the outer side located in the rotation connection post 4 is mounted with an arcuate mounting plate 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com