A self-cooling hob to prevent chips from remaining

A self-cooling, hob technology, applied to components with teeth, gear teeth manufacturing devices, gear teeth, etc., can solve the problems of high cost, various varieties, chip removal and heat dissipation performance can not reach the ideal state, to achieve The effect of reducing the temperature of the hob and prolonging the life of the hob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

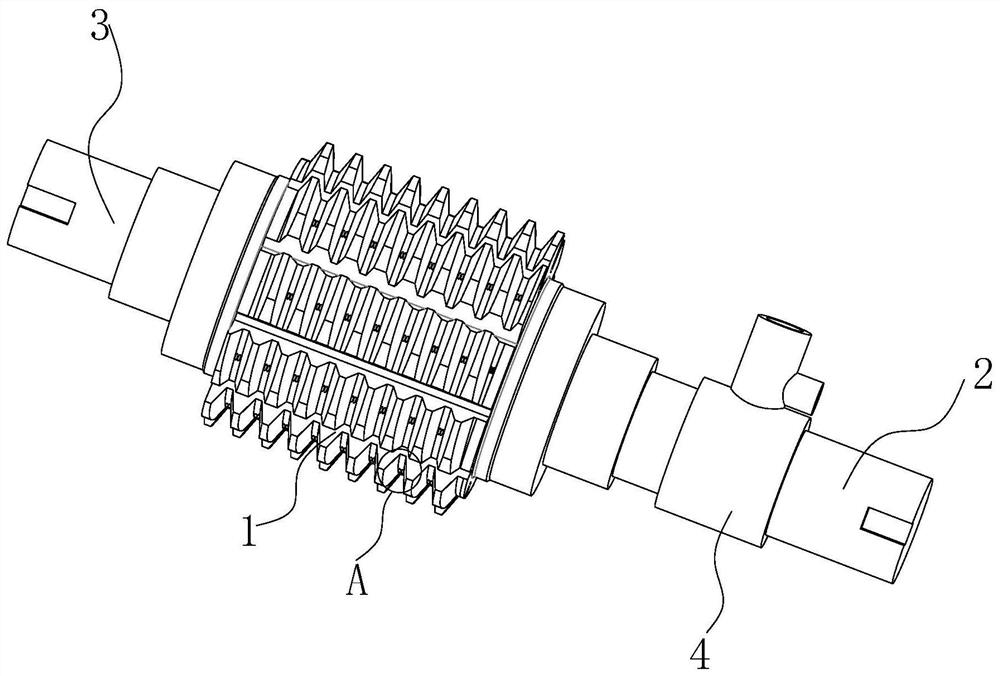

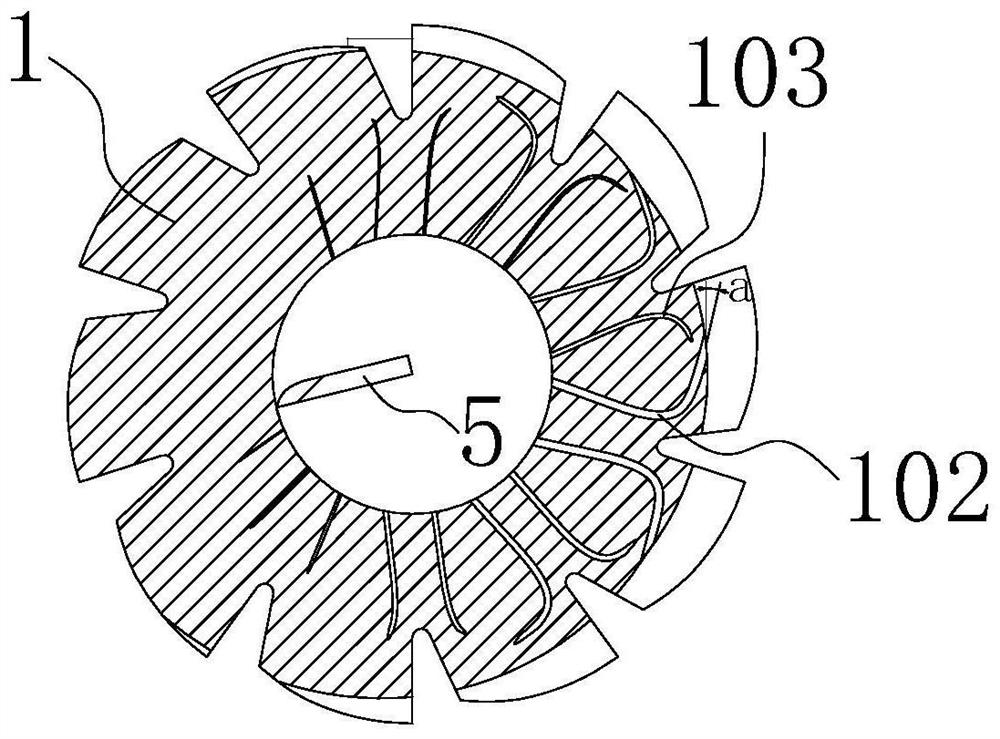

[0037] see Figure 1-7 Shown is a self-cooling hob that prevents chip residue, which is a self-cooling hob that can prevent gear tooth surface damage during processing. Specifically, a self-cooling hob that prevents chips from remaining includes a hob body 1 and a rotating installation head 4 .

[0038] The two ends of the hob body 1 are respectively provided with a first mounting end 2 and a second mounting end 3 , a central hole 101 is opened in the hob body 1 , and a helical blade 5 is fixedly disposed in the central hole 101 .

[0039] A channel 201 is opened inside the first mounting end 2 , and the channel 201 communicates with the central hole 101 , and a through hole 202 is uniformly opened on the circumference side of the first mounting end 2 , and the through hole 202 communicates with the channel 201 .

[0040] The rotating connector 4 is rotatably installed on the first mounting end 2, and the rotating connecting head 4 covers the through hole 202. A dynamic seal ...

Embodiment 2

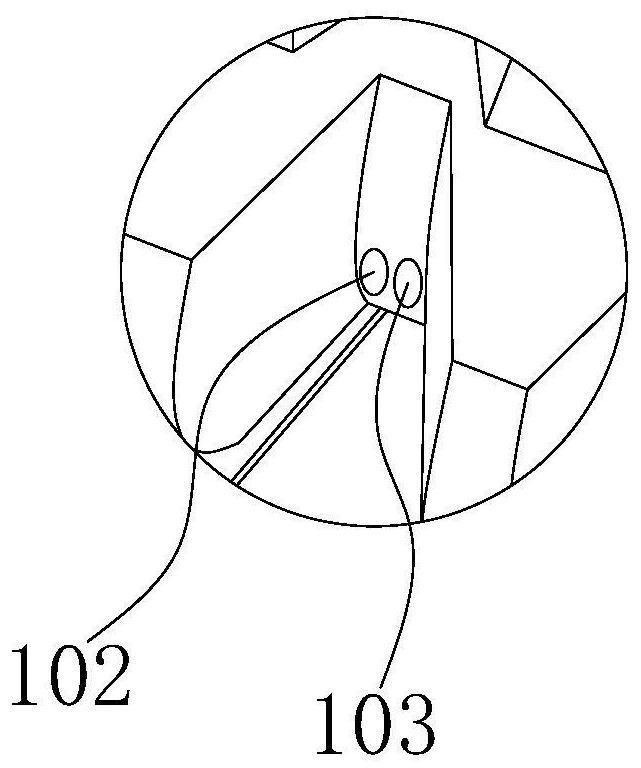

[0048] Another self-cooling hob that prevents chips from remaining is different from Embodiment 1 in that: the direction of the extension line of the liquid outlet of the first curved groove 102 and the second curved groove 103 and the tangential direction of the outlet end form an included angle a , the angle a is 20°.

Embodiment 3

[0050] The difference between another self-cooling hob that prevents chip residue from Embodiment 1 and Embodiment 2 is that: Figure 8 As shown, the pressure relief port 402 on the rotary joint 4 is removed, and a thin through hole 301 is opened on the second installation end 3 , and the thin through hole 301 communicates with the central hole 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com