Stirring tool for removing upper and lower shoulders after friction stir welding of double shoulders and its usage method

A technology for friction stir welding and stirring tools, applied in the field of stirring tools, can solve problems such as difficult disassembly of stirring tools, and achieve the effects of convenient and rapid disassembly, strong adaptability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments. .

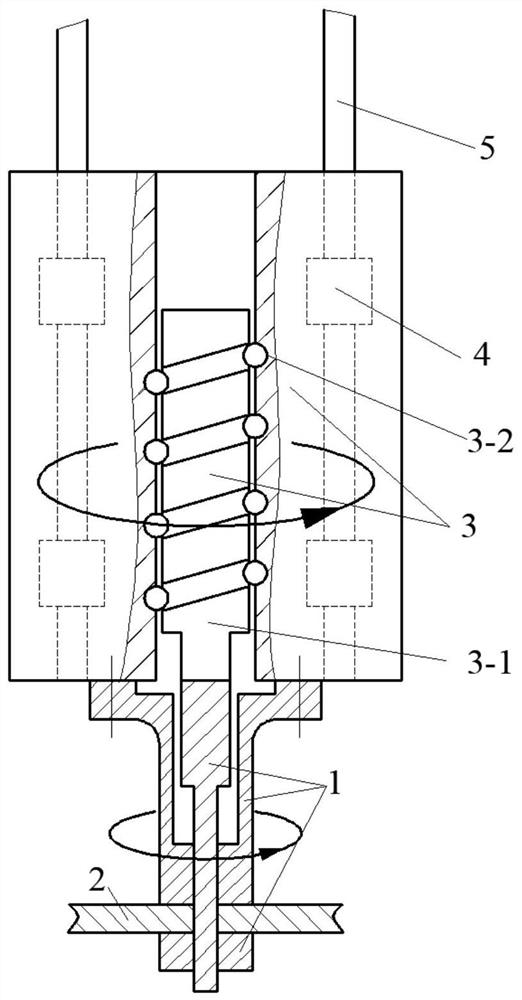

[0027] like Figures 1 to 4 As shown, this embodiment provides a stirring tool suitable for disassembling the upper and lower shaft shoulders after the double shaft shoulder friction stir welding of the closed annular seam and a method of using the same, including the following steps:

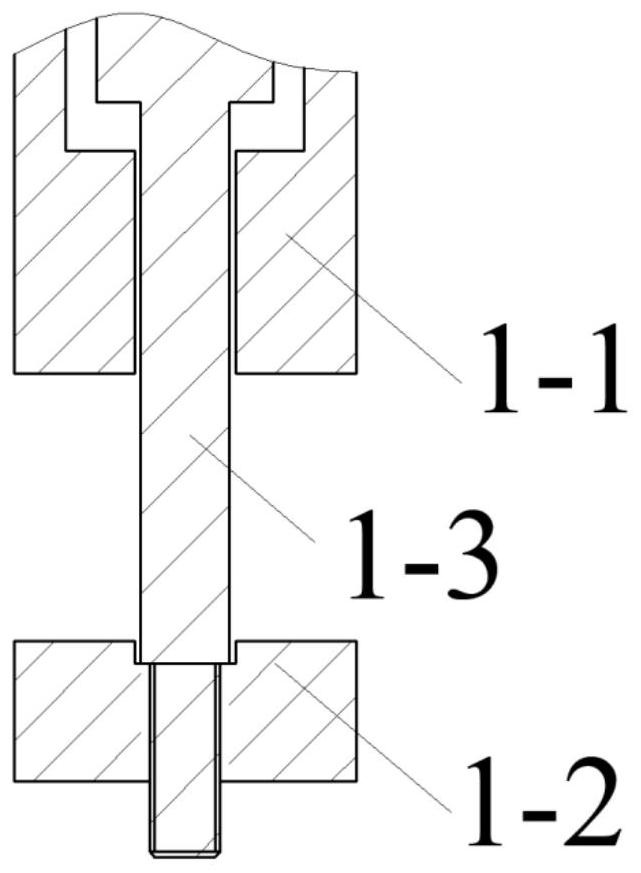

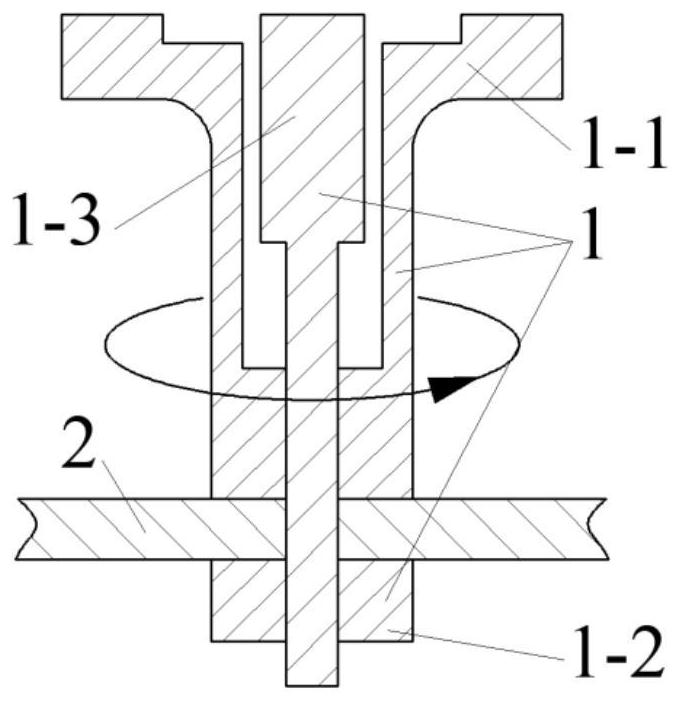

[0028] In the first step, after the double shoulder friction stir welding is completed, the upper shoulder 1-1, the lower shoulder 1-2, and the stirring needle 1-3 continue to rotate and stay at the welding end position for 2s.

[0029] In the second step, the main head 3 is connected with the slider 4 and moves on the guide rail 5 to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com