Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Easy to repair welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

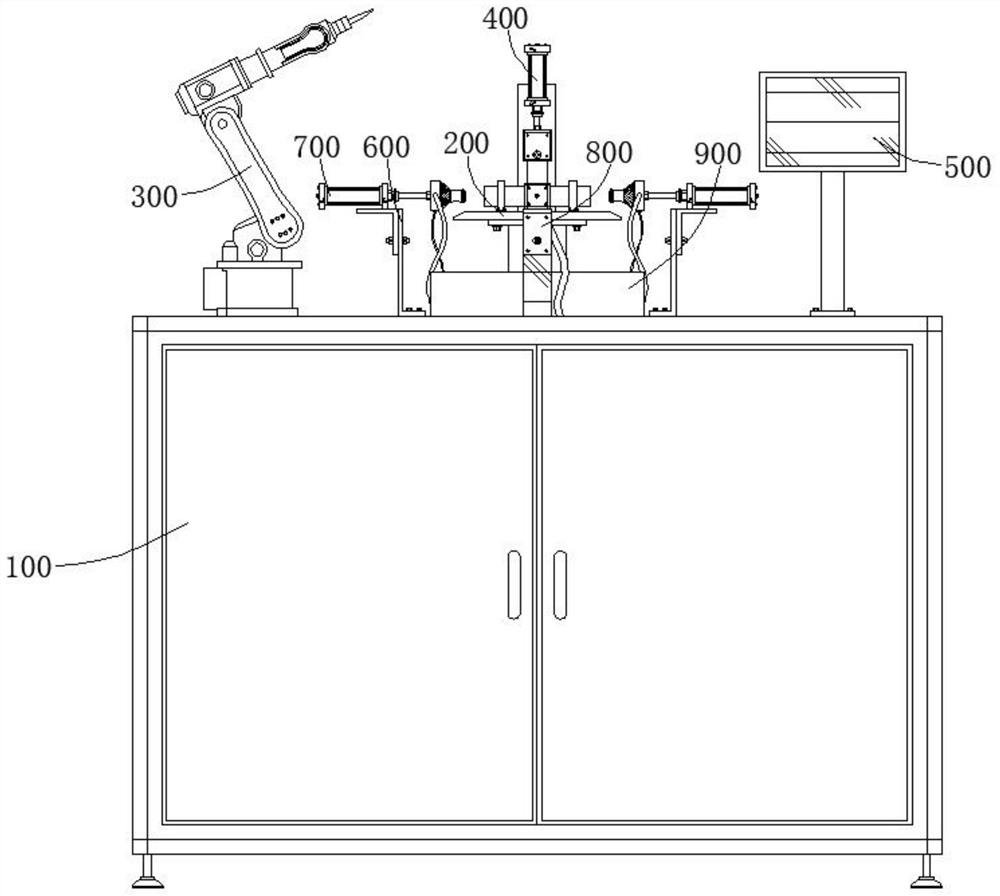

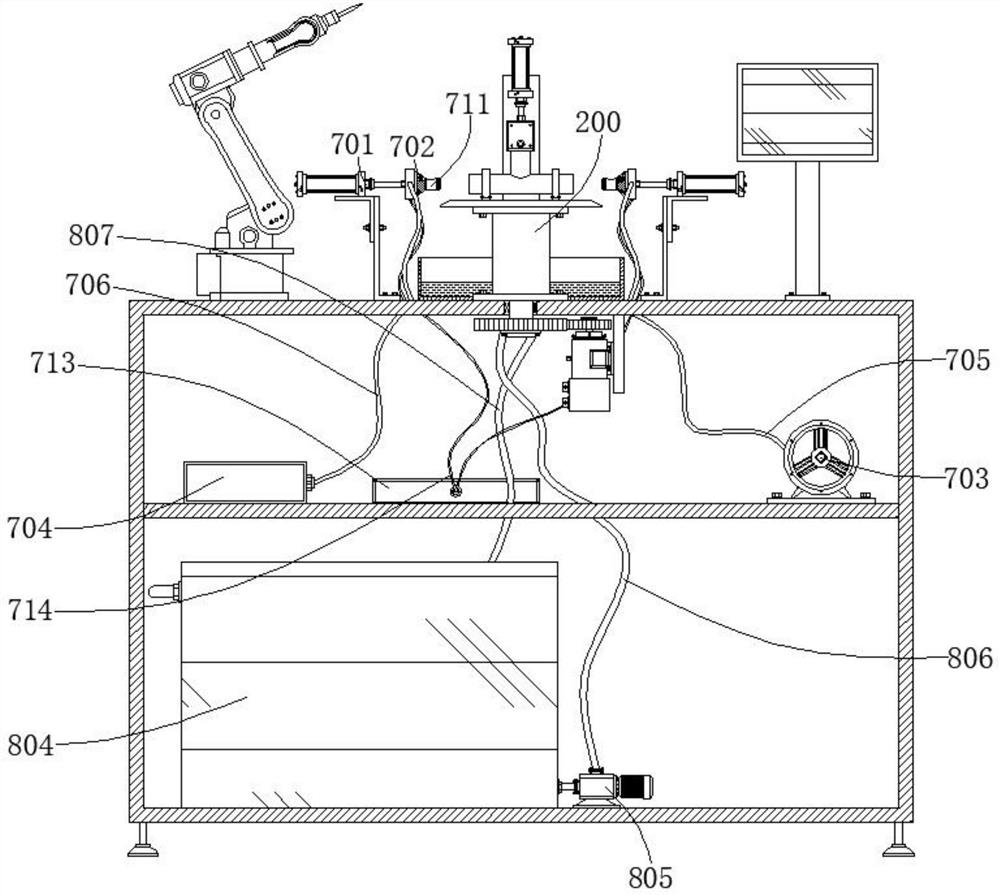

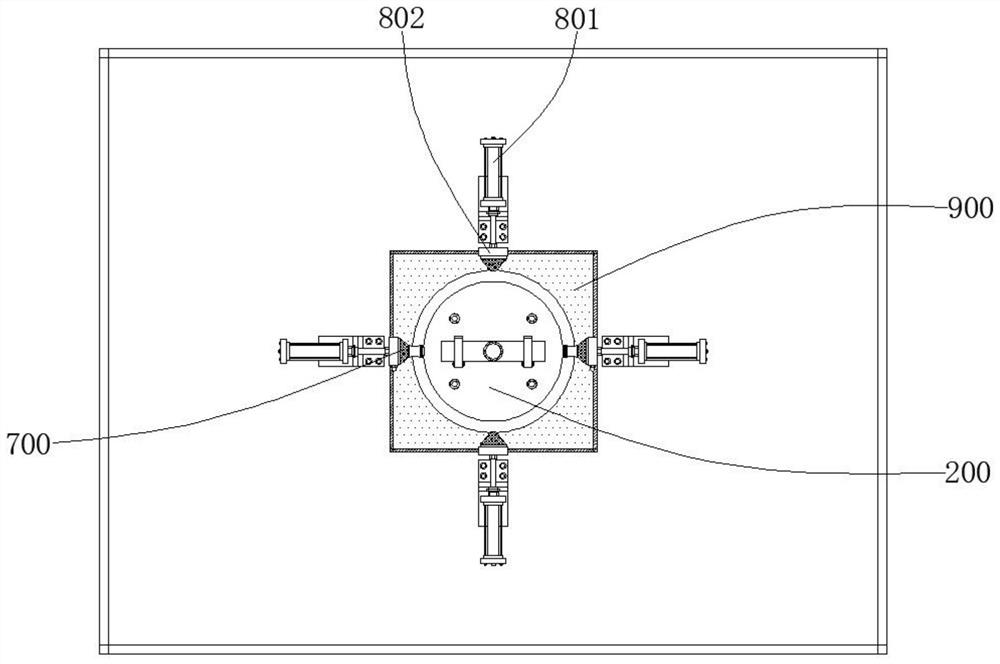

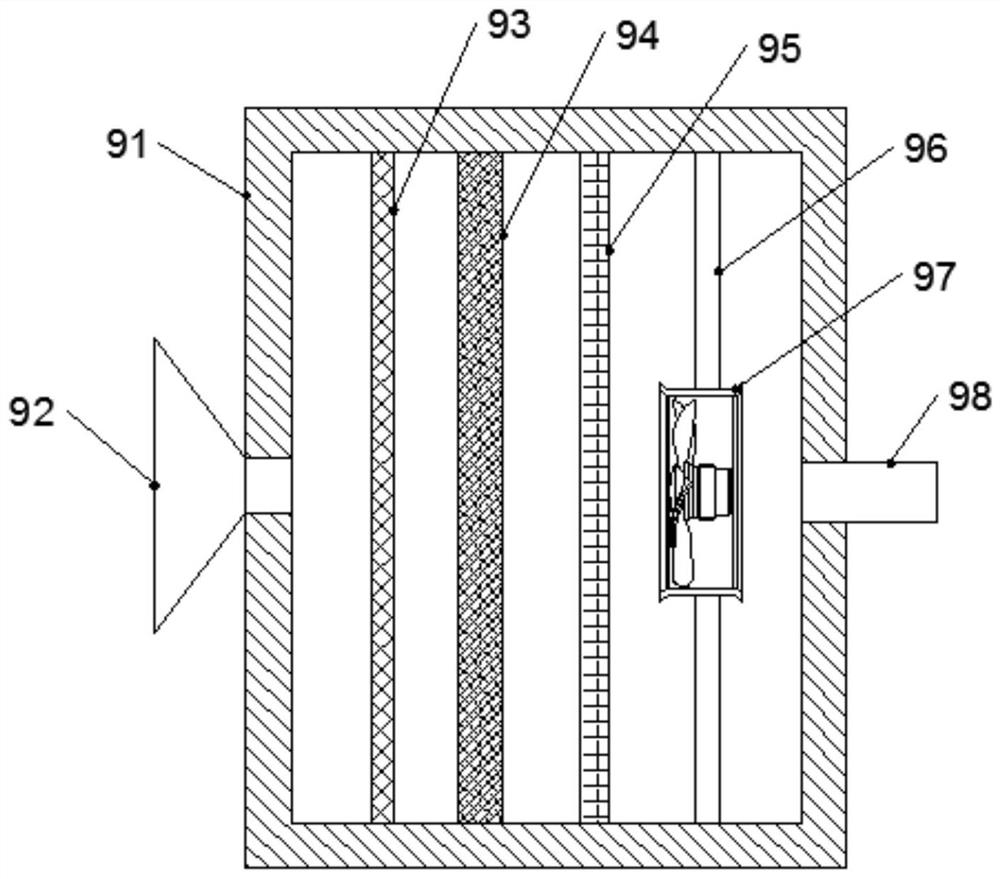

Valve welding and air tightness detection integrated device

ActiveCN113001048AImprove air tightnessPoor air tightnessMeasurement of fluid loss/gain rateWelding/cutting auxillary devicesAir pumpWater collection

The invention belongs to the technical field of valve welding, and particularly relates to a valve welding and air tightness detection integrated device. The device comprises a workbench, a rotary table, a welding robot, a butt joint mechanism, a control and display mechanism, mounting frames, an air tightness detection mechanism, a leakage point detection mechanism and a water collection table. First air cylinders are started to drive two first plugs on the left side and the right side of the rotary table to move relatively, the two ends of a valve are plugged, an air pump is started, compressed air is injected into the valve through an air inlet pipe and an air groove to be pressurized, and meanwhile air injected by the valve enters an air outlet pipe through an air groove of the other first plug; then the air enters a digital display pressure gauge from a pipe opening of the air outlet pipe, the digital display pressure gauge displays the air pressure value, and if the air pressure value displayed by the digital display pressure gauge is equal to the air pressure value applied by the air pump, the air tightness of valve welding is good; and if the air pressure value displayed by the digital display pressure gauge is lower than the air pressure value applied by the air pump, the air tightness of valve welding is poor, and air pressure leakage exists.

Owner:扬州市易通煤矿机械有限公司

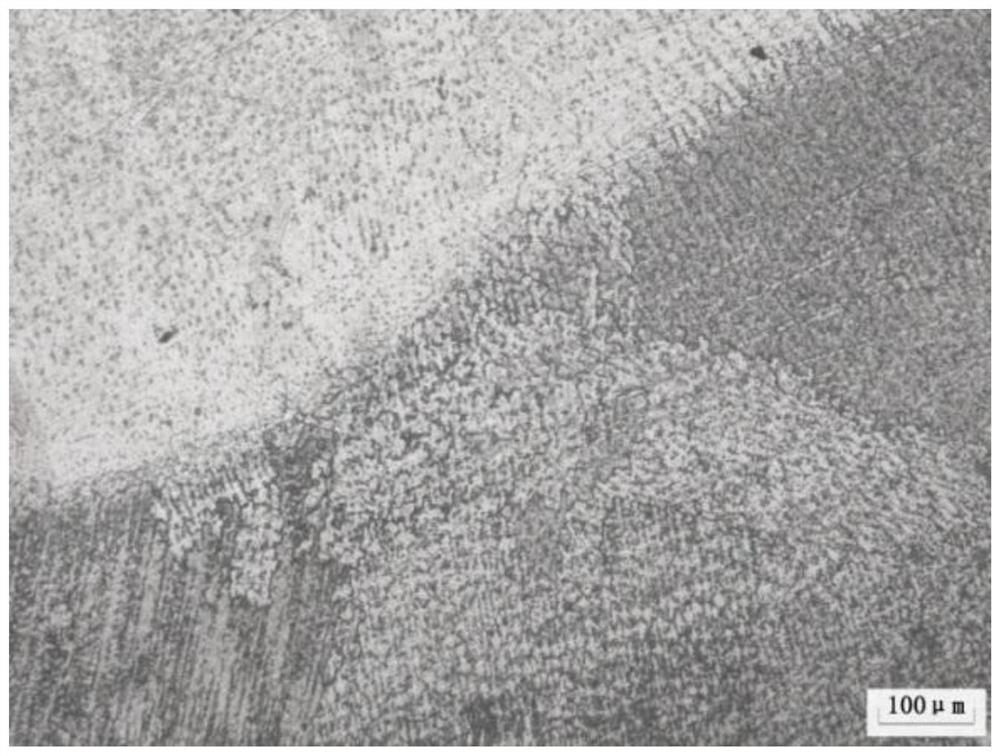

3Cr17NiMo-ESR plastic mold steel

The invention discloses tempering type 3Cr17NiMo-ESR plastic mold steel. The tempering type 3Cr17NiMo-ESR plastic mold steel comprises, by weight percent, 0.30%-0.40% of C, not larger than 1.00% of Si, not larger than 1.00% of Mn, 16.00%-17.50% of Cr, 0.60%-1.00% of Ni, 0.80%-1.30% of Mo, not larger than 0.020% of S, not larger than 0.035% of P and the balance Fe. The plastic mold steel is pre-hardened till the hardness HRC ranges from 30 to 36. The plastic mold steel is good in acid proofing effect, the mirror finishing performance is excellent, the plastic mold steel is suitable for direct mold milling machining and manufacturing and is especially suitable for making a plastic mold with excellent corrosion resistance and polishing performance, and the plastic mold steel is greatly used for machining molds of high-grade transparent decorations, cosmetics containers, food containers and the like.

Owner:湖北志联模具科技有限公司

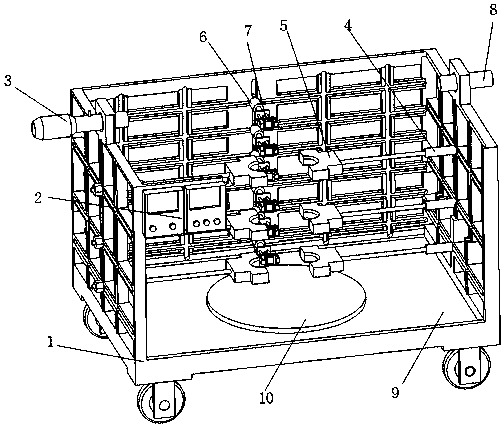

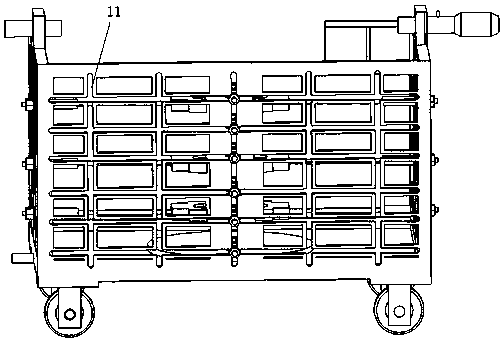

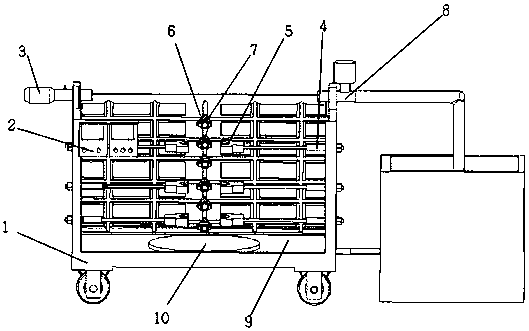

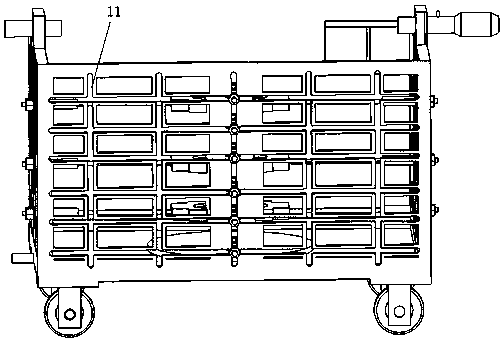

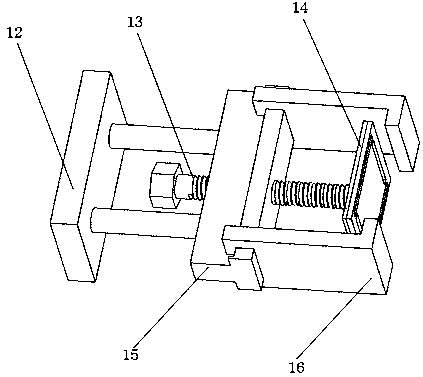

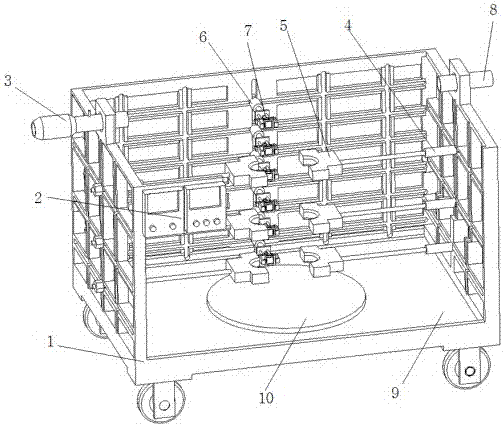

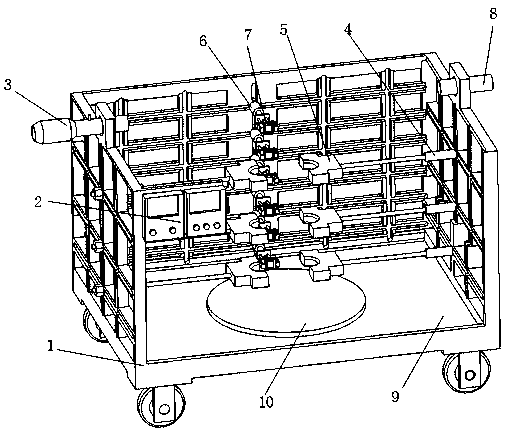

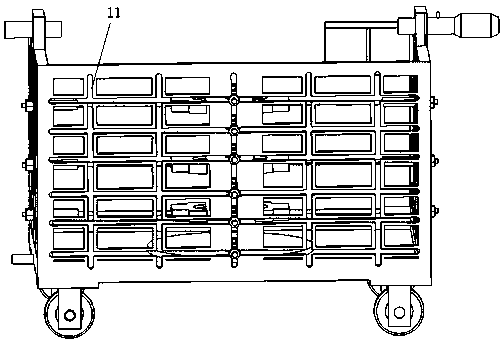

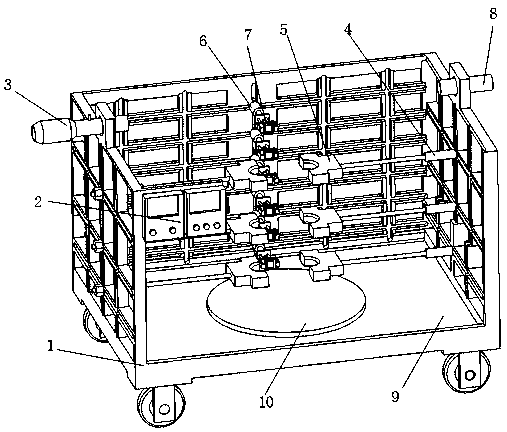

Equipment capable of flexibly detecting air tightness of exhaust manifolds and application method

ActiveCN107607271AKeep dry and cleanEasy to drainDetection of fluid at leakage pointMeasurement of fluid loss/gain rateControl systemPipe fitting

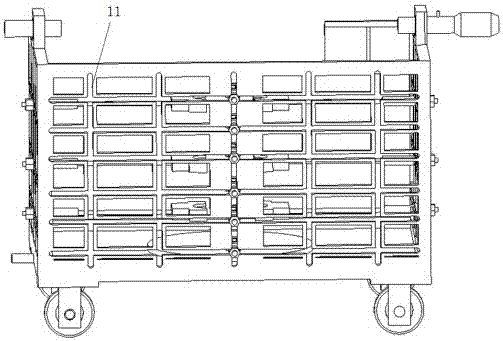

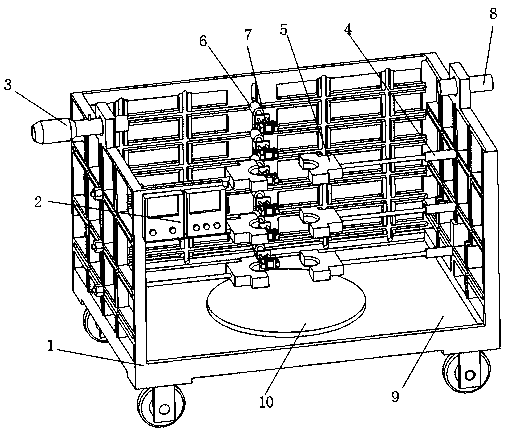

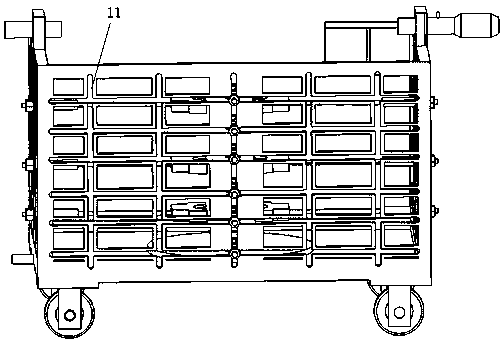

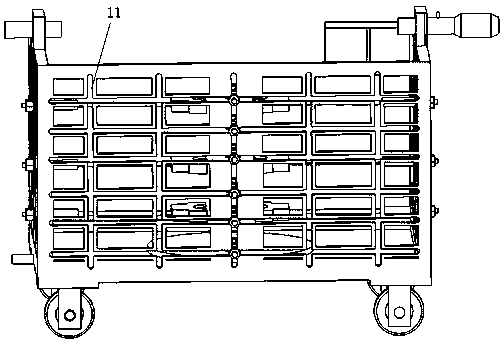

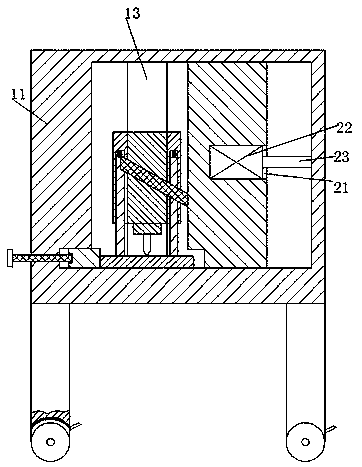

The invention provides equipment capable of flexibly detecting air tightness of exhaust manifolds and an application method. The equipment comprises a detection cart, a starter and an alarm. A plurality of vertical and horizontal slide ways are arranged on three faces of the detection cart, and extend inwardly to form a plurality of clamping devices and sealing devices with claws. The clamping devices and the sealing devices are connected with a power device. The tail of the power device penetrates the vertical and horizontal slide ways and move on the vertical and horizontal slide ways. The detection cart is provided with an automatic water injection pipe fitting and an automatic air delivery pipe fitting. The starter and the alarm are arranged on the outer side of the detection cart, andare connected with a control system through sensors. A water tank is arranged on the bottom surface of the detection cart. High-pressure water compression is applied to detect the air tightness of the manifolds, adjustment can be made flexibly according to differences of the detected manifolds, and the equipment has the advantages of visual and obvious detection effect and applicability to various automotive exhaust manifolds.

Owner:INNOMATEC CHINA TEST & SPECIAL EQUIP TAICANG CO LTD

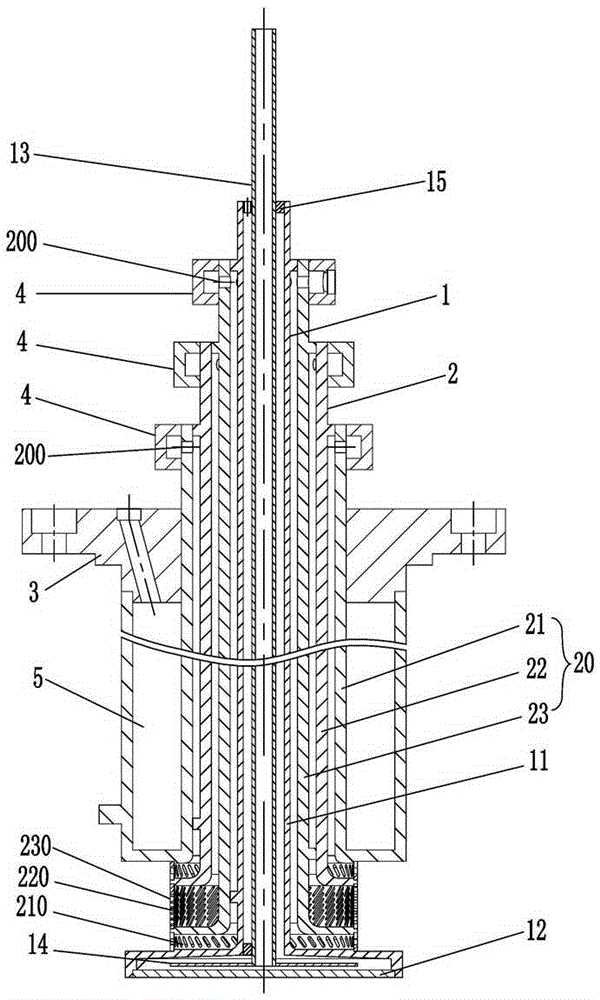

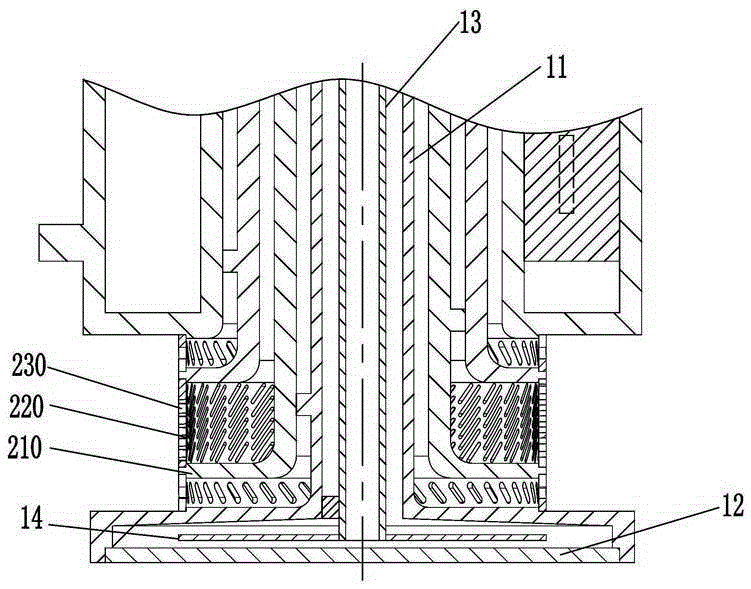

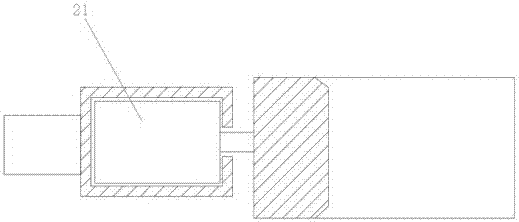

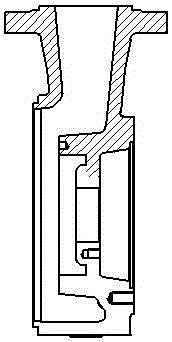

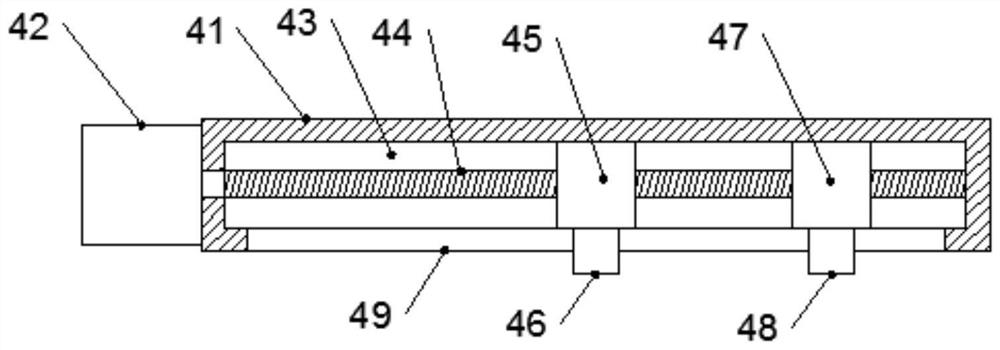

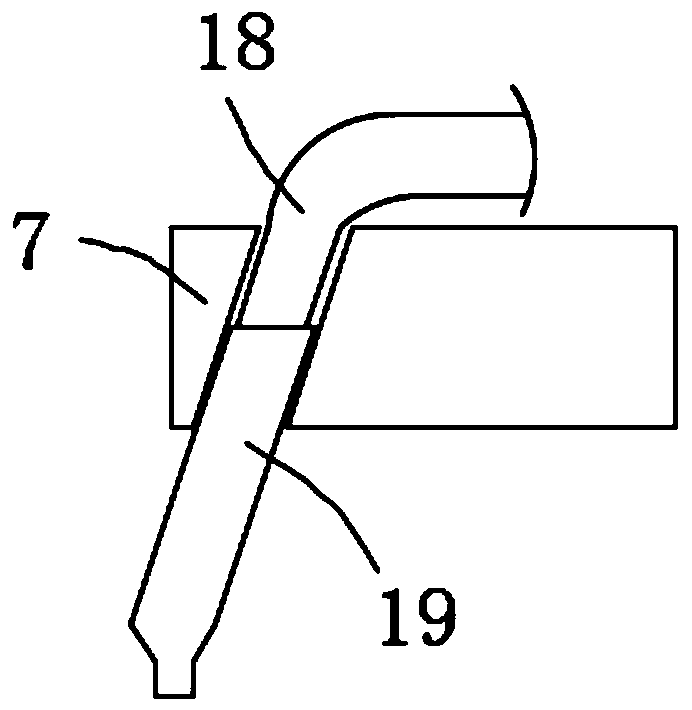

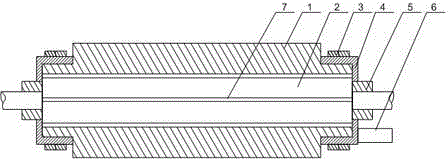

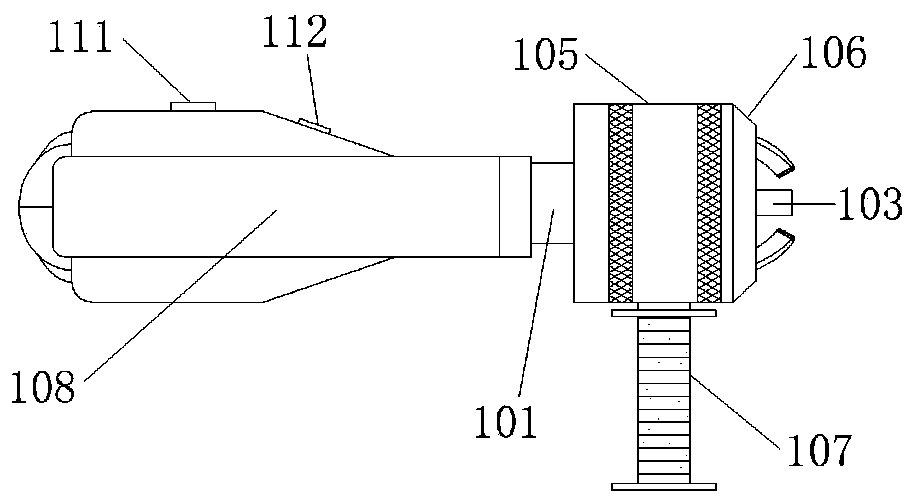

High-temperature-resistant horizontal multi-layer gas inlet device for SiC epitaxy

InactiveCN105256369AEasy maintenanceEasy to repair weldingFrom chemically reactive gasesWeld seamEngineering

The invention discloses a high-temperature-resistant horizontal multi-layer gas inlet device for SiC epitaxy. The device comprises an inner water jacket assembly, a gas inlet assembly and a mounting flange which are sequentially coaxially nested from inside to outside, wherein the gas inlet assembly comprises multiple layers of gas inlet rings and sealing rings which are coaxially nested in a spaced manner, the multiple layers of gas inlet rings are elongated layer by layer from outside to inside, a gas inlet is formed in the top end of each gas inlet ring, the tail end of each gas inlet ring is folded outwards in the radial direction to form a flared folded surface, the sealing rings are welded to the peripheries of the gas inlets and arranged on the outside of the mounting flange, the sealing rings are spaced and the sealing ring on the outermost layer and the mounting flange are also spaced. The device has the benefits as follows: welding seams formed between each sealing ring and the corresponding gas inlet ring are exposed out of the outer surface of the gas inlet device and are convenient to maintain; the sealing rings are arranged in a spaced manner, so that repair welding is facilitated.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Energy-saving equipment for automatic detection of air tightness of exhaust manifolds and utilization method of energy-saving equipment

ActiveCN107607270AThe test result is accurateHigh degree of automationDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWater storagePipe fitting

The invention provides energy-saving equipment for automatic detection of air tightness of exhaust manifolds and a utilization method of the energy-saving equipment. The energy-saving equipment comprises a detection vehicle, a starter and alarm and a water storage pool. Three surfaces of the detection vehicle are provided with a plurality of longitudinal and transverse slide ways, and a pluralityof clamping devices and sealing devices with hook claws extend inwardly from the longitudinal and transverse slide ways. The clamping devices and the sealing devices are connected with power devices,and tails of the power devices penetrate the longitudinal and transverse slide ways and move on the longitudinal and transverse slide ways. The detection vehicle is provided with an automatic water injection pipe fitting and an automatic air delivery pipe fitting, and the starter and alarm is arranged on the outer side of the detection vehicle and connected with a control system through a sensor.The water storage pool is arranged on the right side of the detection vehicle and provided with a circulating water device connected with the detection vehicle. By means of high-pressure compression for detection of air tightness of the exhaust manifolds, the energy-saving equipment is direct and evident in detection effect and high in applicability and is provided with a water circulation systemto play a great role in energy saving.

Owner:LONGKOU VEHICLE VITTA

Equipment capable of automatically detecting air tightness of exhaust manifolds and using method thereof

ActiveCN107884142AEasy to operateThe test result is accurateMeasurement of fluid loss/gain rateControl systemEngineering

The invention provides a piece of equipment capable of automatically detecting the air tightness of exhaust manifolds and a using method thereof. The equipment includes a detection vehicle, a starterand an alarm. Multiple longitudinal and horizontal slide ways are arranged on three sides of the detection vehicle. Multiple clamping devices and sealing devices with claws extend from the inside of the longitudinal and horizontal slide ways. The clamping devices and the sealing devices are connected with a power device. The tail of the power device penetrates the longitudinal and horizontal slideways, and the power device slides on the longitudinal and horizontal slide ways. The detection vehicle is provided with an automatic water injection pipe and an automatic gas transmission pipe. The starter and the alarm are arranged outside the detection vehicle, and are connected with a control system through a sensor. The clamping devices are further provided with stepper motors. The air tightness of exhaust manifolds is detected through water seepage under high pressure, and adjustment can be made automatically according to different detected manifolds. The detection effect is visual and obvious. The equipment is suitable for various kinds of automobile exhaust manifolds.

Owner:东兴市思丰海产品实业有限公司

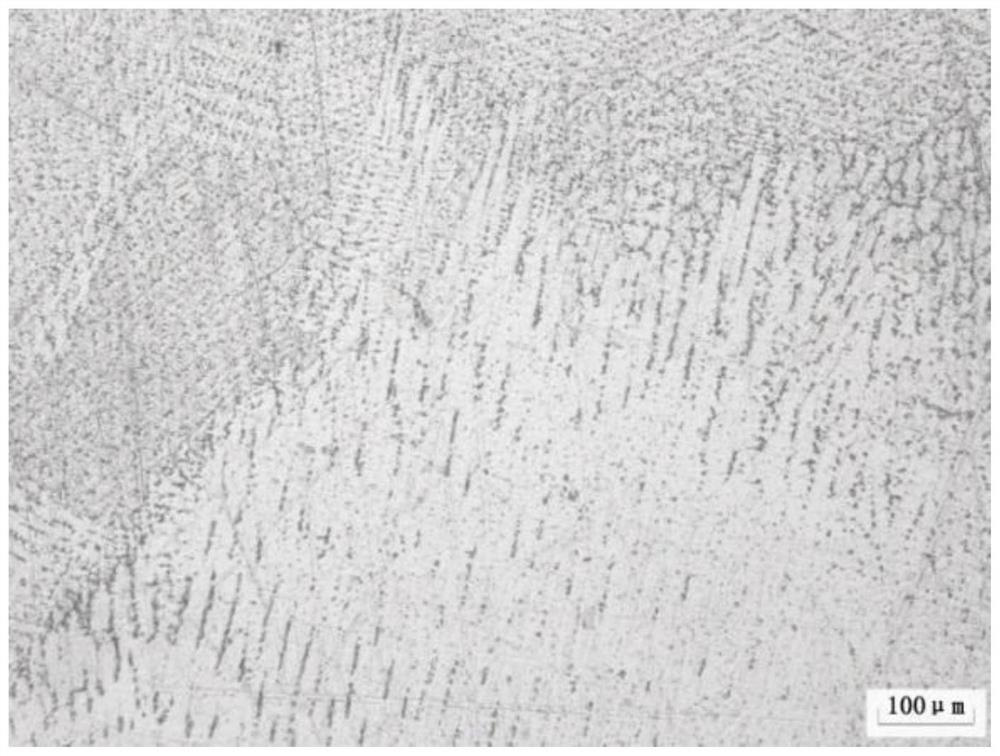

Solder and Repair Welding Method for Casting Defects of K418b Superalloy Guide

ActiveCN112453754BImprove high temperature performancePromote formationArc welding apparatusWelding/cutting media/materialsWeld seamSuperalloy

The invention belongs to the field of welding technology, and relates to a solder used for casting defects of a K418B superalloy guide and a repair welding method; the solder composition and mass percentage are: C: 0.03-0.07; Cr: 21.5-24.0; Nb: 3.2-4.2 ; Mo: 8.5~10.5; Ti: 0~0.5; Al: 0~0.5; P: ≤0.015; S: ≤0.015; O: ≤0.015; N: ≤0.01; Frequency pulse argon arc welding technology, supplemented by pre-weld preheating, post-weld slow cooling and post-weld spot shot peening, can repair casting defects on the guide, and can be used for K418B casting superalloy casting shrinkage porosity, shrinkage cavity, Repair welding of defects such as undercasting, wear and cracks; the welding fluidity of the solder is good, the weld shape is good, the repaired welding joint has no cracks and unfused defects after fluorescence and X-ray inspection, and the average strength of the repaired welding joint at room temperature reaches 885MPa, It is better than the technical requirements of the part material standard.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

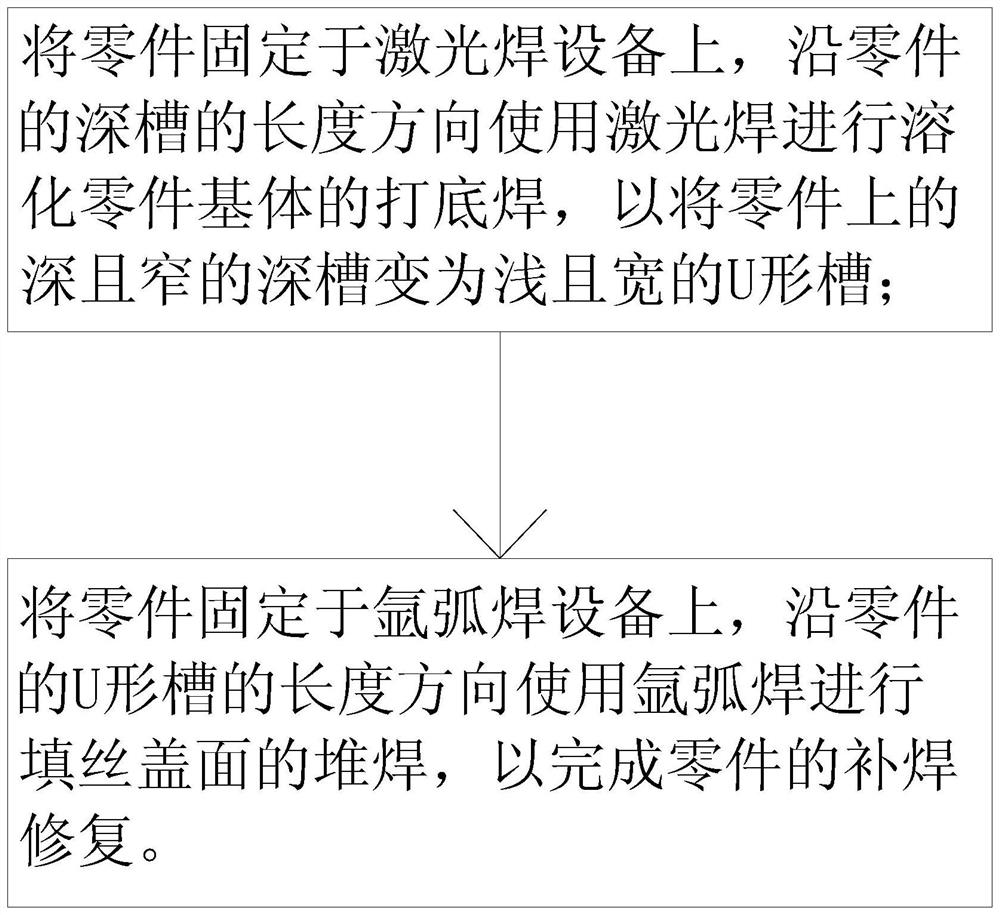

Repair welding method for deep groove of blade casting

PendingCN114101913AReduce distortionEnough machining allowanceLaser beam welding apparatusHeat-affected zoneStructural engineering

The invention discloses a repair welding method for a deep groove of a blade casting, which comprises the following steps: firstly, melting a base body of a part by adopting laser welding equipment to carry out backing welding, and under the condition of not filling wires, enabling a base body material of the part to flow towards the bottom of the deep groove after being melted to form a laser welding seam so as to ensure that the bottom of the deep groove of the part is penetrated through and reduce the dilution rate of a base material; due to the fact that the laser welding energy density is high, the width of a heat affected zone is small, and heat input is small, part deformation is reduced, meanwhile, a deep and narrow deep groove in the part is changed into a shallow and wide U-shaped groove, and next-step repair welding of the part is facilitated; then high-frequency argon arc welding is adopted for conducting wire filling cover face surfacing on the U-shaped groove, the enough surfacing size is guaranteed, it is guaranteed that the part has enough machining allowance in follow-up machining after the part is repaired through repair welding, meanwhile, the high-frequency argon arc welding enables electric arc capacity to be concentrated, heat input is low, and a heat affected zone is smaller through superposition of high-frequency current and electric arc contraction; and a welding seam is narrower, deformation and cracking of parts are greatly reduced, and grain growth is inhibited.

Owner:CHINA HANGFA SOUTH IND CO LTD

Repair welding tool for oil storage barrel assembly

InactiveCN105057948ASimple structureEasy to implementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOil storage

The invention discloses a repair welding tool for an oil storage barrel assembly. Two right-angled rods are arranged on the left side and the right side of the front portion of a welding table side by side. Each right-angled rod is composed of a first circular rod and a second circular rod. The upper ends of the first circular rods are welded to the front portion of the welding table. The first circular rods are arranged forwards. The lower ends of the first circular rods and the lower ends of the second circular rods are perpendicularly fixed. The upper ends of the second circular rods are suspended. Circular rods are arranged on the left side and the right side of the top face of supporting square steel side by side and perpendicular to the top face of the supporting square steel; a rectangular frame is arranged between the two circular rods; and the upper ends of the two circular rods are perpendicularly fixed to frame bars at the left end and the right end of the rectangular frame respectively. By the adoption of the repair welding tool, repair welding can be conveniently and rapidly performed on the oil storage barrel assembly, so that circumferential welding between an oil storage barrel in the oil storage barrel assembly and an n-shaped supporting lug is achieved, and insufficient welding is avoided.

Owner:重庆川东减震制造有限公司

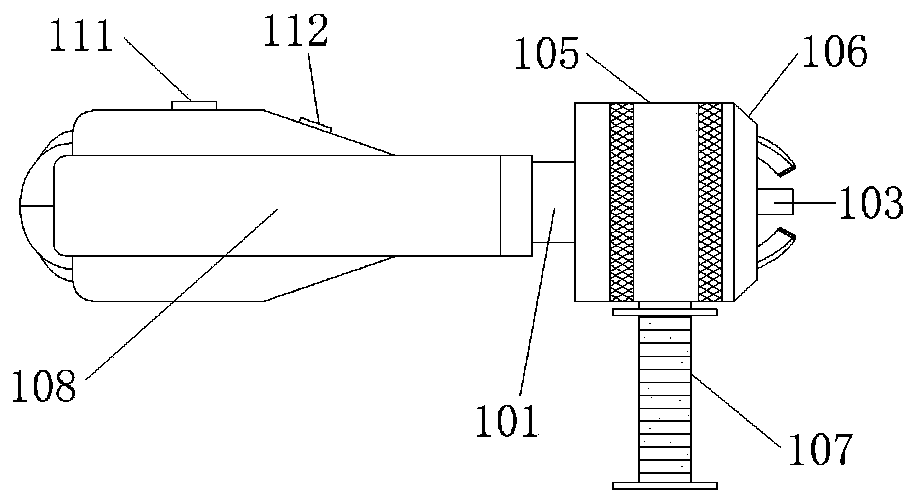

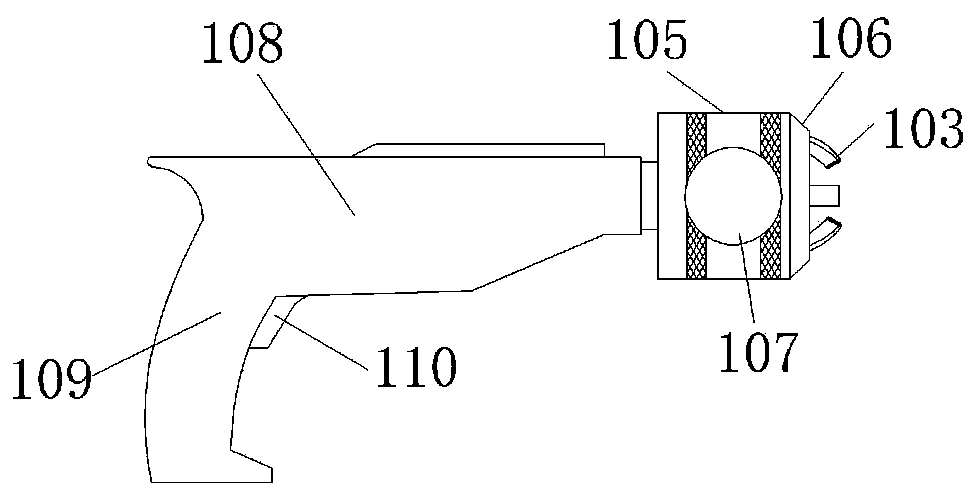

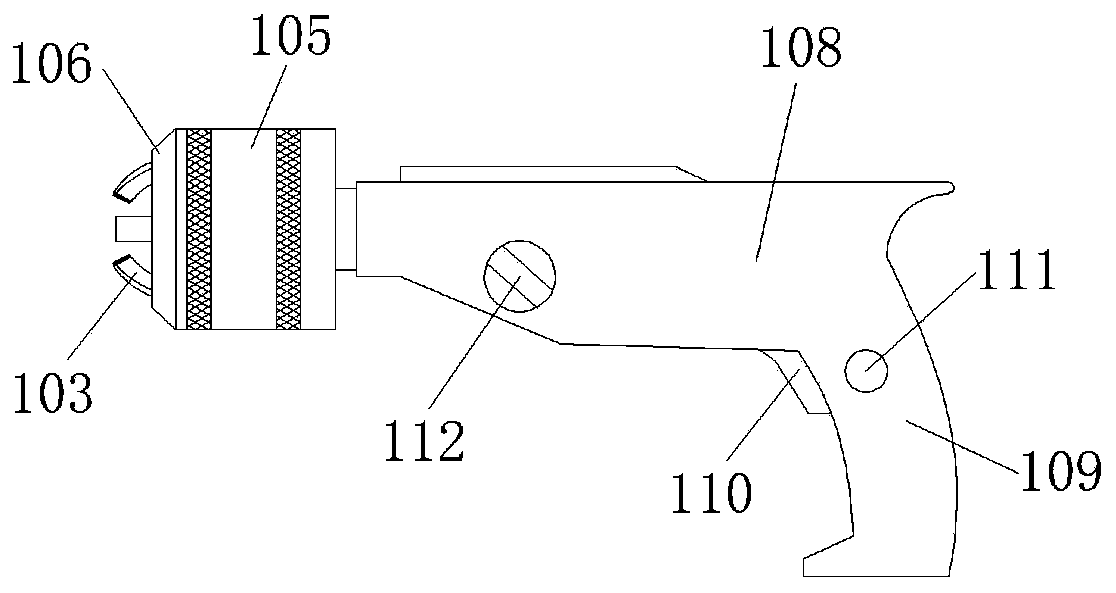

Sampling machine

PendingCN110261162ASimple structureEasy to operateWithdrawing sample devicesMilling cutterEngineering

The invention relates to a sampling machine. The sampling machine includes a sampling head; the sampling head includes a threaded seat, a rotating seat and a milling cutter; the milling cutter is arranged in the guiding groove of the rotating seat and located on one side of a rotating shaft; the end head of the milling cutter faces toward to the rotating shaft, and the tail end of the milling cutter is deviated from the rotating shaft; the rotating seat controls the milling cutter to rotate around the rotating shaft, and the threaded seat is provided with a conical surface matching the rotating surface of the milling cutter; the conical surface is provided with a thread, and the side, facing toward the conical surface, of the milling cutter is provided with a tooth pattern section; and the milling cutter rotates along the conical surface, and the thread meshes with the tooth pattern section to form a screw-pair structure of a leading screw. Improvement can be performed on the clamping jaw mechanisms of existing electric drills; the milling cutter can be driven to perform forward or reverse rotation around the rotating shaft through the rotation of the rotating seat, and the milling cutter can also perform telescoping movement during rotation, so that micro-damage sampling work can be accomplished; and the sampling machine has the advantages of being simple in structure, convenient in operation, good in stability, flat in sampled part and easy in welding and repairing after taking.

Owner:国能神福(晋江)热电有限公司 +2

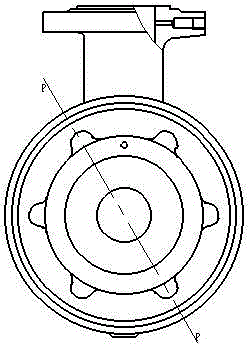

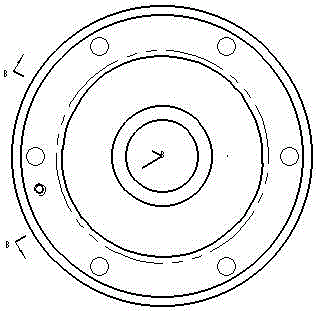

Novel multi-stage centrifugal pump device and manufacturing method

InactiveCN105201861ASimple structureImprove the finishSpecific fluid pumpsPump componentsSurface finishAgricultural engineering

The invention discloses a novel multi-stage centrifugal pump device which mainly comprises a shaft box, a water inlet section, a water outlet section, a middle section, a stuffing box and a perforated rod. A perforated seat used for fixing the perforated rod and a base are not arranged on the water inlet section and the water outlet section, the perforated seat is arranged on the shaft box or the perforated rod is fixedly welded to the water inlet section and the water outlet section, a main body of the stuffing box is segmented from a cooling device, and therefore the surface smooth finish is high. The invention further discloses a manufacturing method of the novel multi-stage centrifugal pump device, and parts which do not make contact with corrosive media are made of cast iron materials instead of stainless steel materials. The novel multi-stage centrifugal pump device mainly aims at a multi-stage centrifugal pump made of the stainless steel materials, and on the basis of achieving the same effects, the novel multi-stage centrifugal pump device and the manufacturing method have the advantages of precisely manufacturing, saving the cost, improving the efficiency and reducing energy and resources.

Owner:长沙神舟水泵厂

A device capable of automatically detecting the airtightness of an exhaust manifold and its application method

ActiveCN107884142BEasy to operateThe test result is accurateMeasurement of fluid loss/gain rateControl systemElectric machine

The invention provides a piece of equipment capable of automatically detecting the air tightness of exhaust manifolds and a using method thereof. The equipment includes a detection vehicle, a starterand an alarm. Multiple longitudinal and horizontal slide ways are arranged on three sides of the detection vehicle. Multiple clamping devices and sealing devices with claws extend from the inside of the longitudinal and horizontal slide ways. The clamping devices and the sealing devices are connected with a power device. The tail of the power device penetrates the longitudinal and horizontal slideways, and the power device slides on the longitudinal and horizontal slide ways. The detection vehicle is provided with an automatic water injection pipe and an automatic gas transmission pipe. The starter and the alarm are arranged outside the detection vehicle, and are connected with a control system through a sensor. The clamping devices are further provided with stepper motors. The air tightness of exhaust manifolds is detected through water seepage under high pressure, and adjustment can be made automatically according to different detected manifolds. The detection effect is visual and obvious. The equipment is suitable for various kinds of automobile exhaust manifolds.

Owner:东兴市思丰海产品实业有限公司

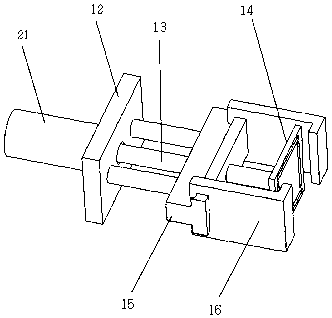

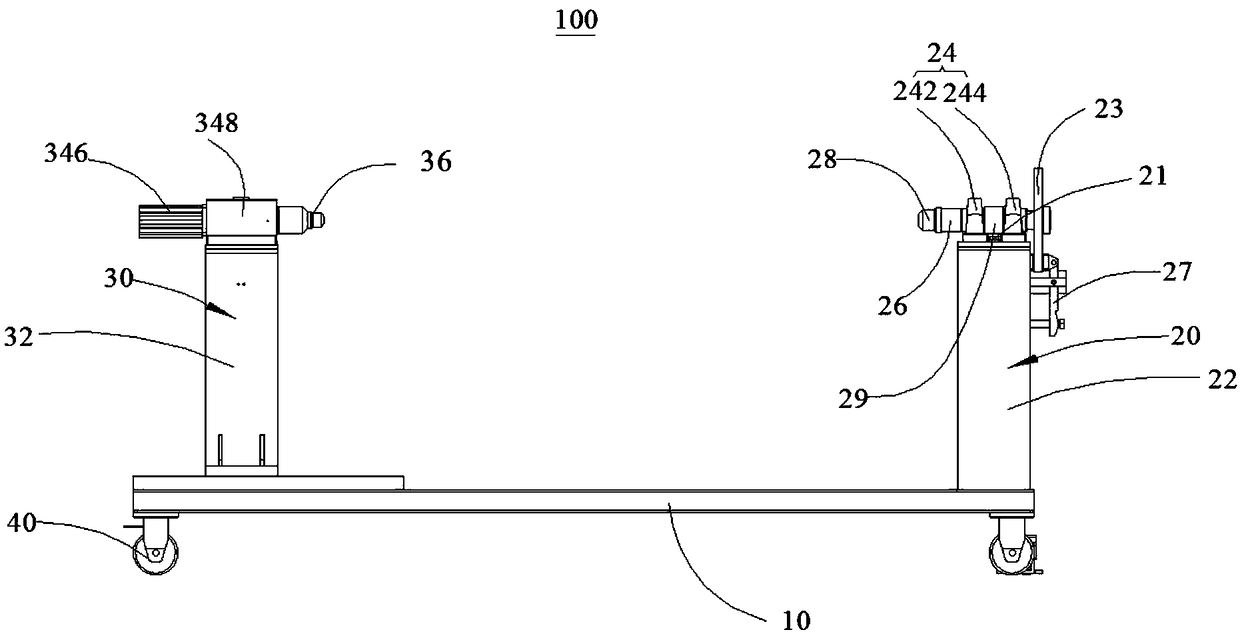

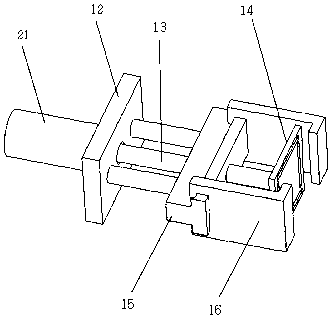

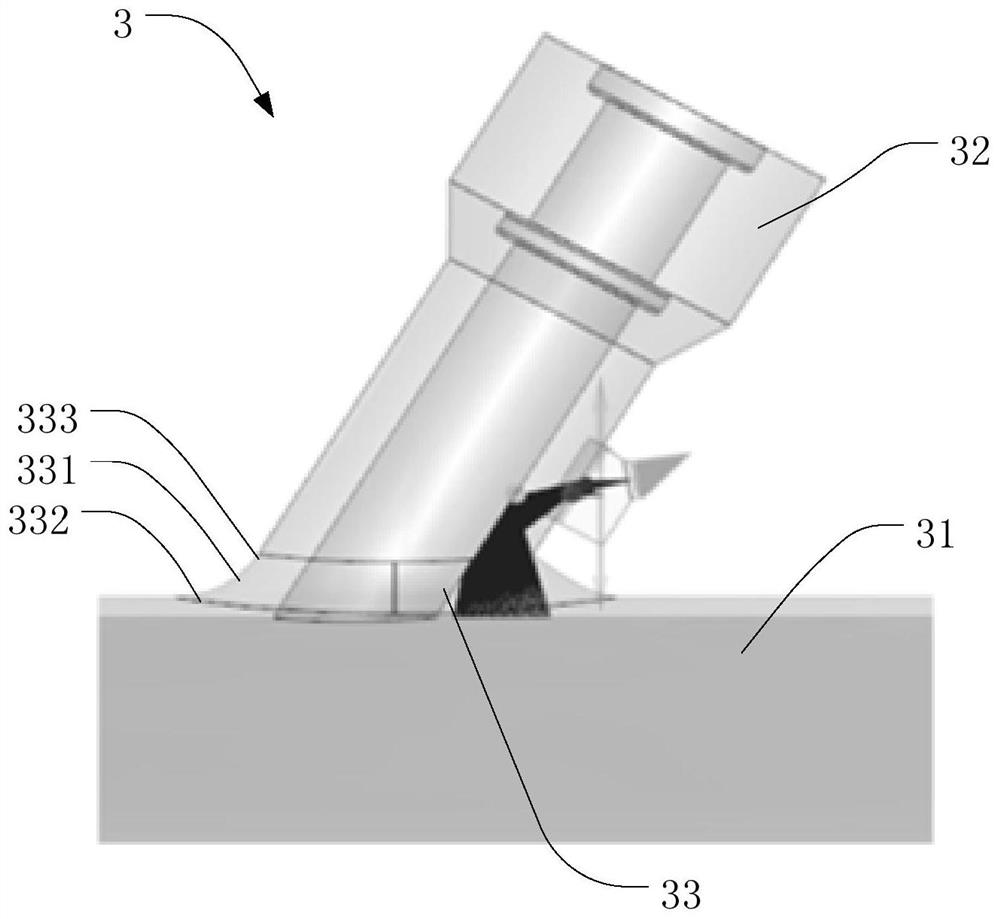

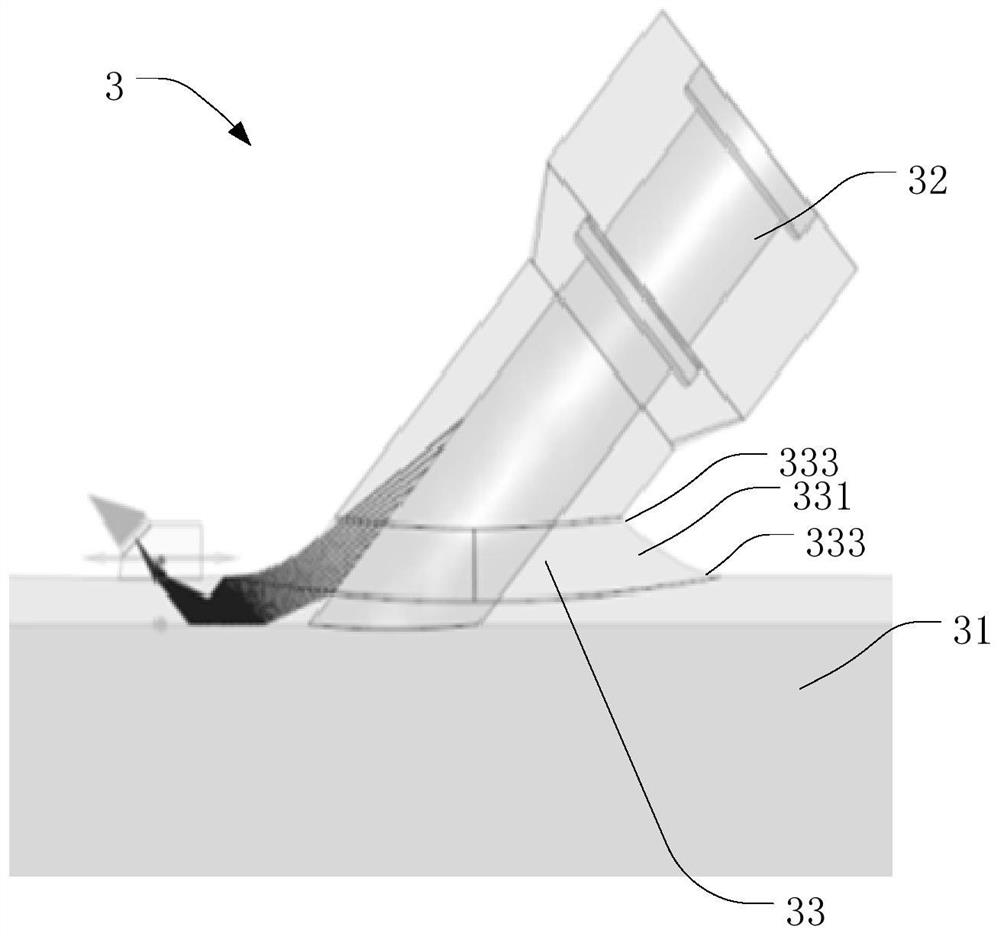

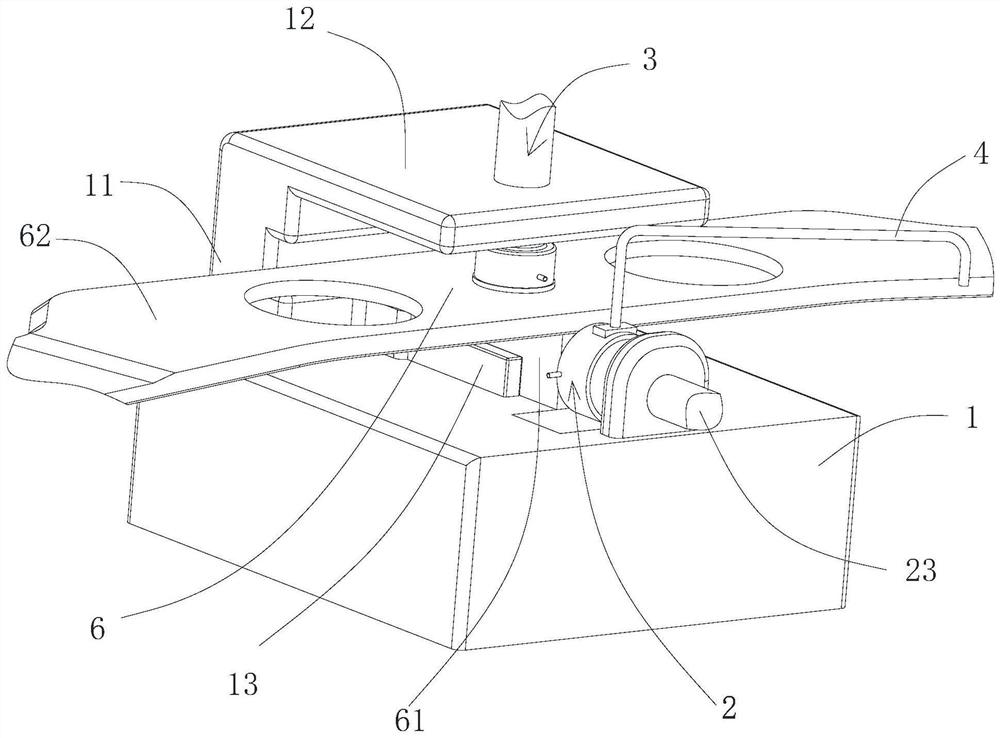

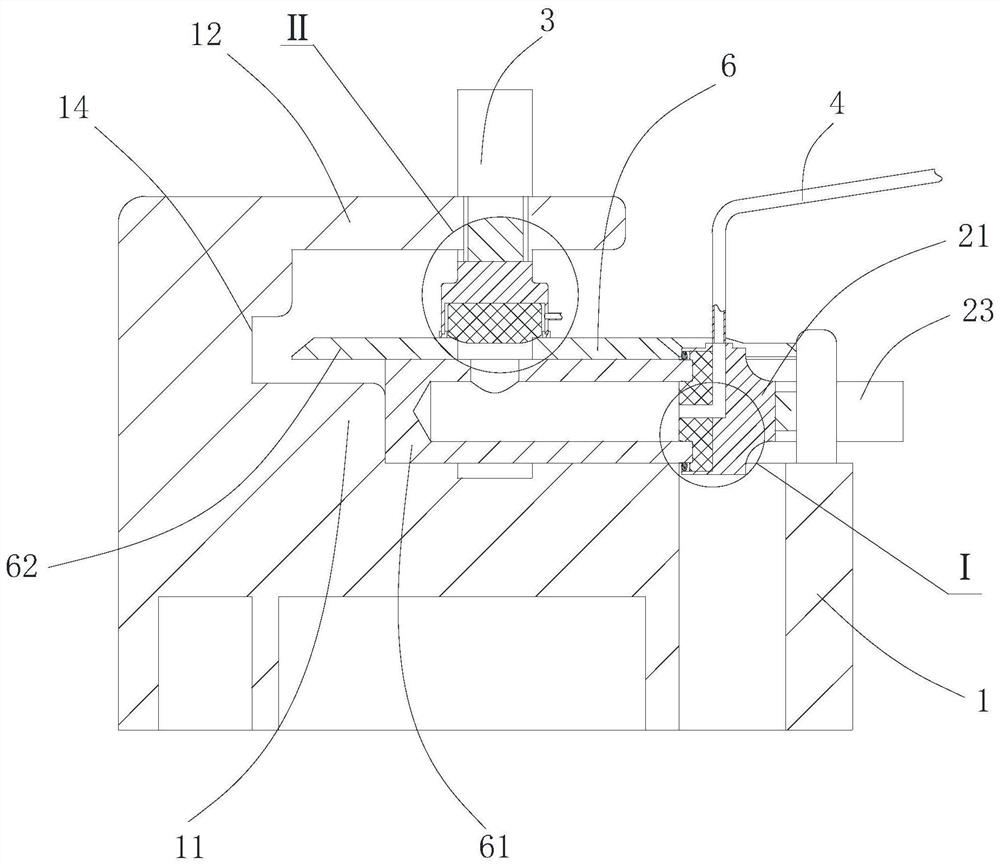

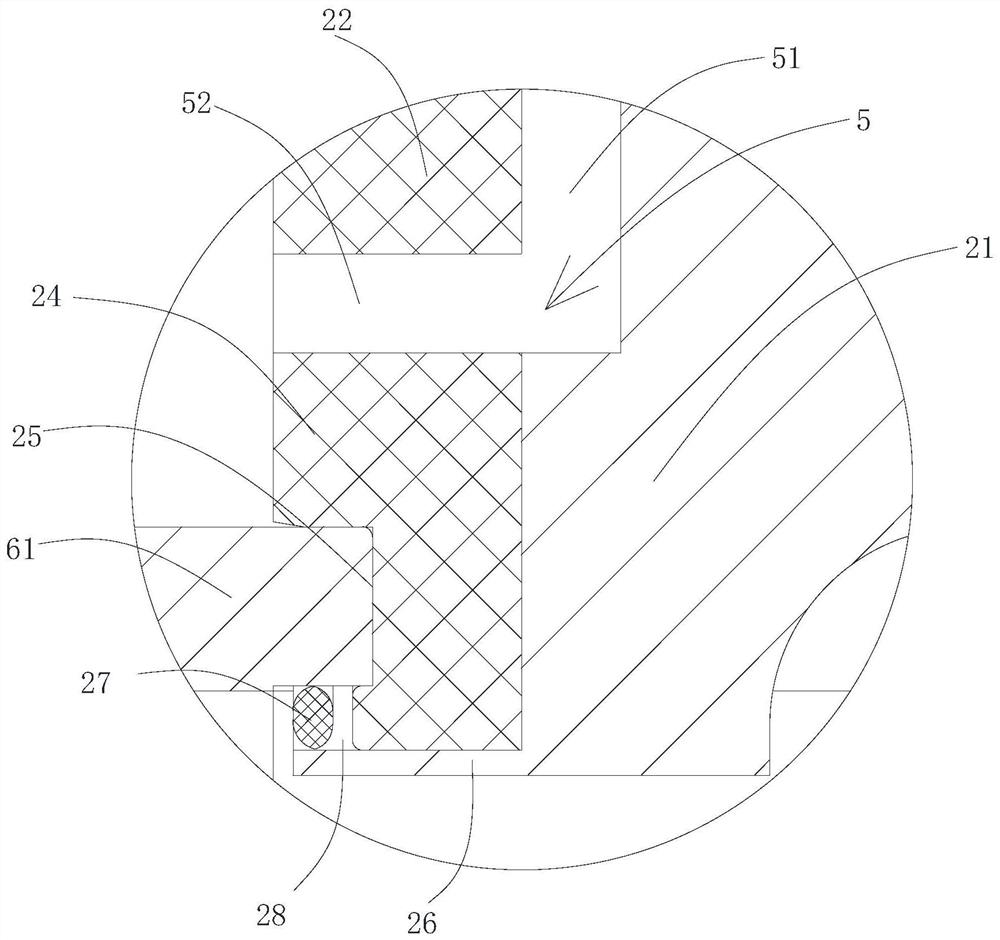

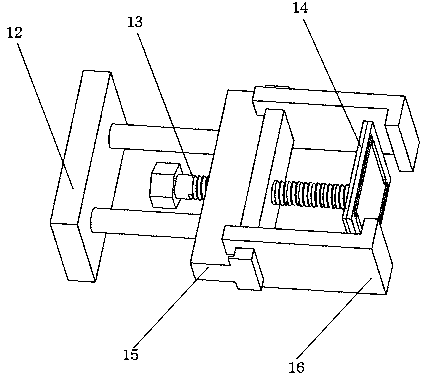

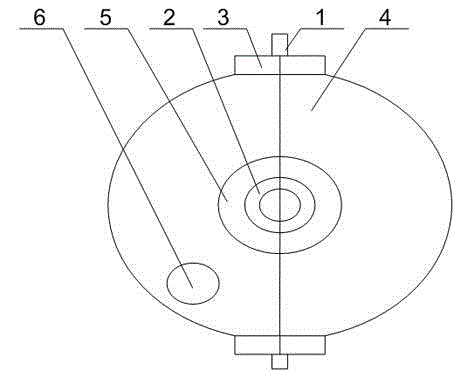

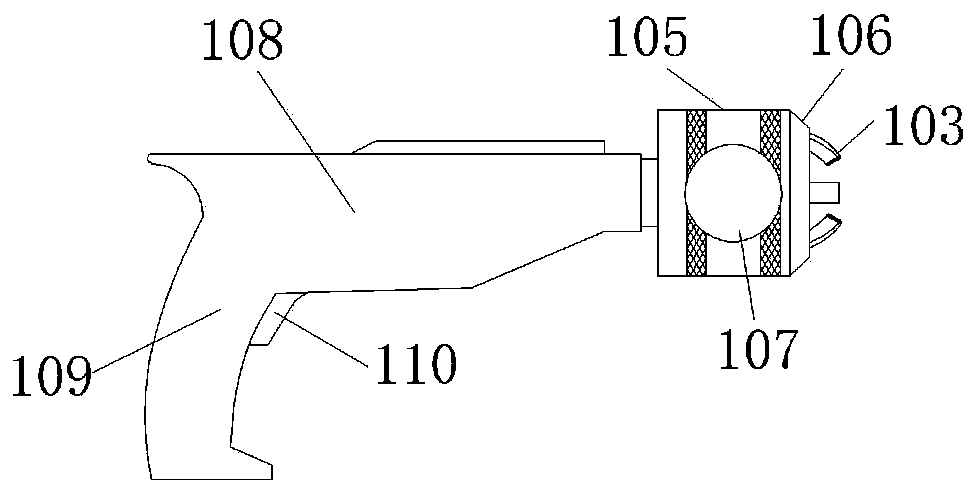

Repairing welding tool

PendingCN108526801AEasy to repair weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChange positions

The invention provides a repairing welding tool. The repairing welding tool comprises a base, a first locating mechanism and a second locating mechanism. The first locating mechanism and the second locating mechanism are oppositely arranged on the base. Te first locating mechanism comprises a first support, a rotating unit and a brake unit. The rotating unit and the brake unit are both arranged onthe first support. The brake unit is used for limiting the rotating unit from rotating. The second locating mechanism comprises a second support and a support unit. The second support is arranged onthe base. The support unit is arranged on the second support. According to the repairing welding tool, when the rotating unit rotates, a workpiece fixed to the rotating unit can be driven to rotate; when repairing welding is required, a worker does not need to crouch or change positions for working around the tool and only needs to rotating the rotating unit, and rotary adjustment can be conductedon the position needing repairing welding; and the worker can conduct reparing welding conveniently.

Owner:株洲汇隆实业发展有限公司

A device capable of flexibly detecting the airtightness of an exhaust manifold and its application method

ActiveCN107607271BKeep dry and cleanEasy to drainDetection of fluid at leakage pointMeasurement of fluid loss/gain rateControl systemPipe fitting

The invention provides equipment capable of flexibly detecting air tightness of exhaust manifolds and an application method. The equipment comprises a detection cart, a starter and an alarm. A plurality of vertical and horizontal slide ways are arranged on three faces of the detection cart, and extend inwardly to form a plurality of clamping devices and sealing devices with claws. The clamping devices and the sealing devices are connected with a power device. The tail of the power device penetrates the vertical and horizontal slide ways and move on the vertical and horizontal slide ways. The detection cart is provided with an automatic water injection pipe fitting and an automatic air delivery pipe fitting. The starter and the alarm are arranged on the outer side of the detection cart, andare connected with a control system through sensors. A water tank is arranged on the bottom surface of the detection cart. High-pressure water compression is applied to detect the air tightness of the manifolds, adjustment can be made flexibly according to differences of the detected manifolds, and the equipment has the advantages of visual and obvious detection effect and applicability to various automotive exhaust manifolds.

Owner:INNOMATEC CHINA TEST & SPECIAL EQUIP TAICANG CO LTD

Method for repairing roller head for rock wool production

The invention discloses a method for repairing a roller head for rock wool production. The method comprises the following steps of taking out a damaged roller head, cutting off defect parts of the roller head and a roller neck of a roller, polishing and cleaning an end face, inserting the roller head and the roller neck into a pouring mold sand box, preheating the parts of the roller head and theroller neck, which need to be welded, pouring molten iron into the pouring mold sand box, welding the roller head and the roller neck, and after the molten iron is poured and cooled to the normal temperature, completing welding between the roller head and the roller neck; and conducting repair welding and polishing treatment on the parts with the welding defects through welding and polishing equipment. According to the method, through cutting off the defect parts of the roller head and the roller neck firstly, polishing and cleaning the end face, and then conducting pouring and welding betweenthe roller head and the roller neck in the pouring mold sand box, firm connection between the roller head and the roller neck is guaranteed; and meanwhile, repair welding treatment is conducted on the connecting position through the welding and polishing equipment, so that the repair rate of the roller is high, and the repair effect is good.

Owner:安徽岩棉建材科技有限公司

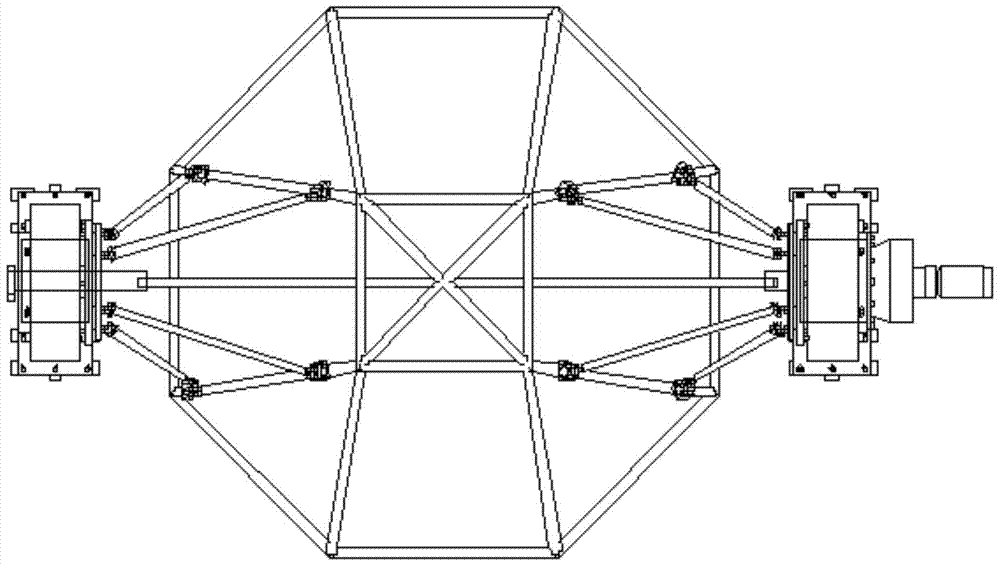

Stirring tool for removing upper and lower shoulders after friction stir welding of double shoulders and its usage method

ActiveCN112548311BEasy to disassembleEasy to repair weldingNon-electric welding apparatusStructural engineeringMechanical engineering

The invention provides a stirring tool suitable for disassembling the upper and lower shoulders after friction stir welding of double-shaft shoulders in a closed ring seam and its use method. The double-shaft shoulder stirring tool consists of three parts: an upper shoulder, a lower shoulder and a stirring needle. The upper shaft shoulder and the stirring needle are clearance fit, the lower shaft shoulder and the stirring needle are connected by threads and the axial direction is limited by steps. After the double-shaft shoulder friction stir welding is completed, the head of the main machine continues to rotate and stays at the welding end position for 1 to 5 seconds; the head of the main machine and the retracting shaft drive the stirring tool up as a whole, and the lower shoulder and the stirring pin assembly move down as a whole, Make the upper and lower shaft shoulders separate from the material to be welded in a rotating state; after the upper and lower shaft shoulders are completely separated from the welded plate, the main shaft and the retracting shaft stop rotating, and use a disassembly tool to separate the lower shaft shoulder from the stirring needle; move the main machine head Pull out the upper shoulder and the stirring pin from the material to be welded, leaving only a keyhole with the diameter of the stirring pin on the plate to be welded.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

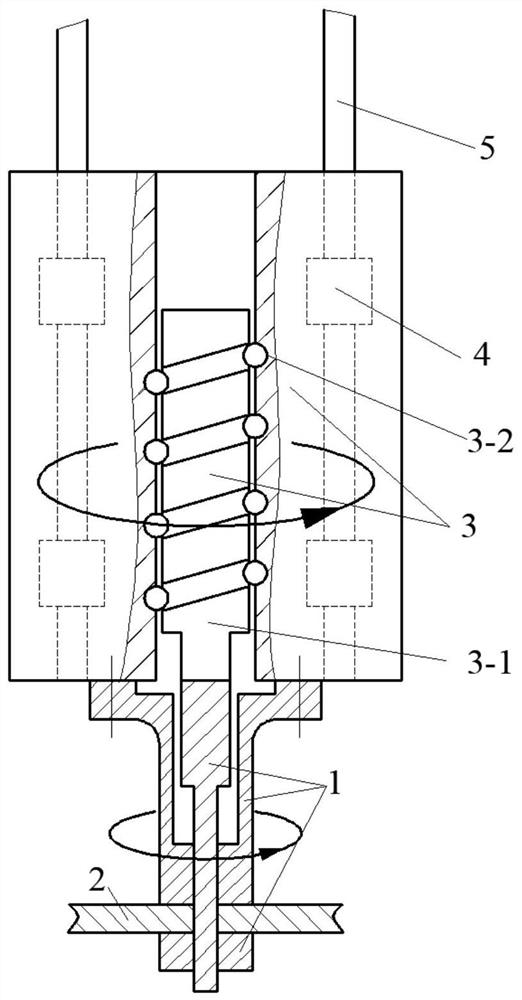

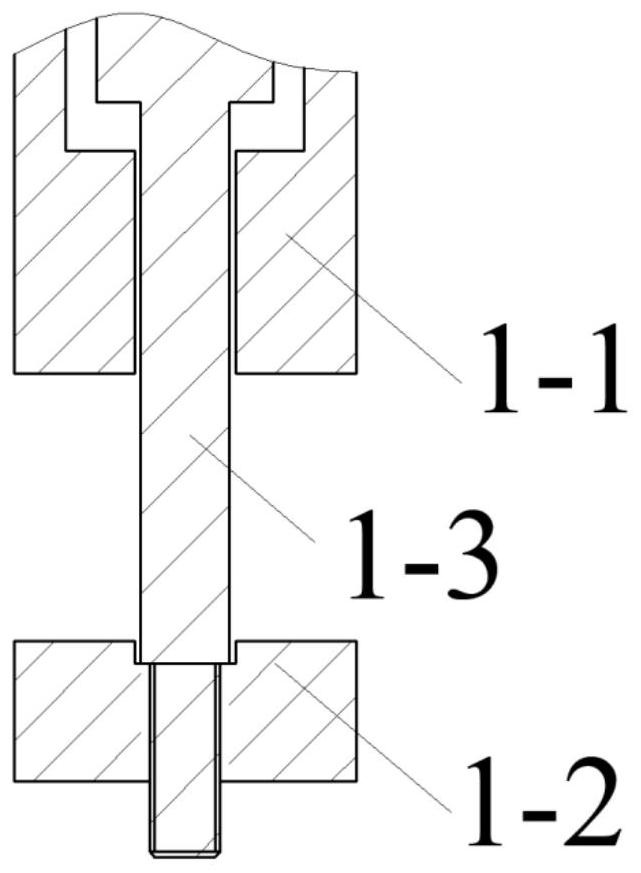

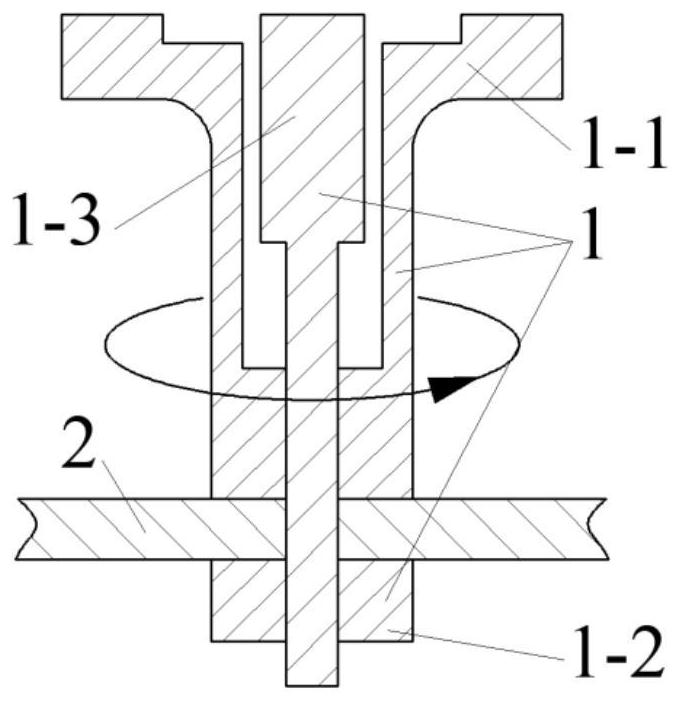

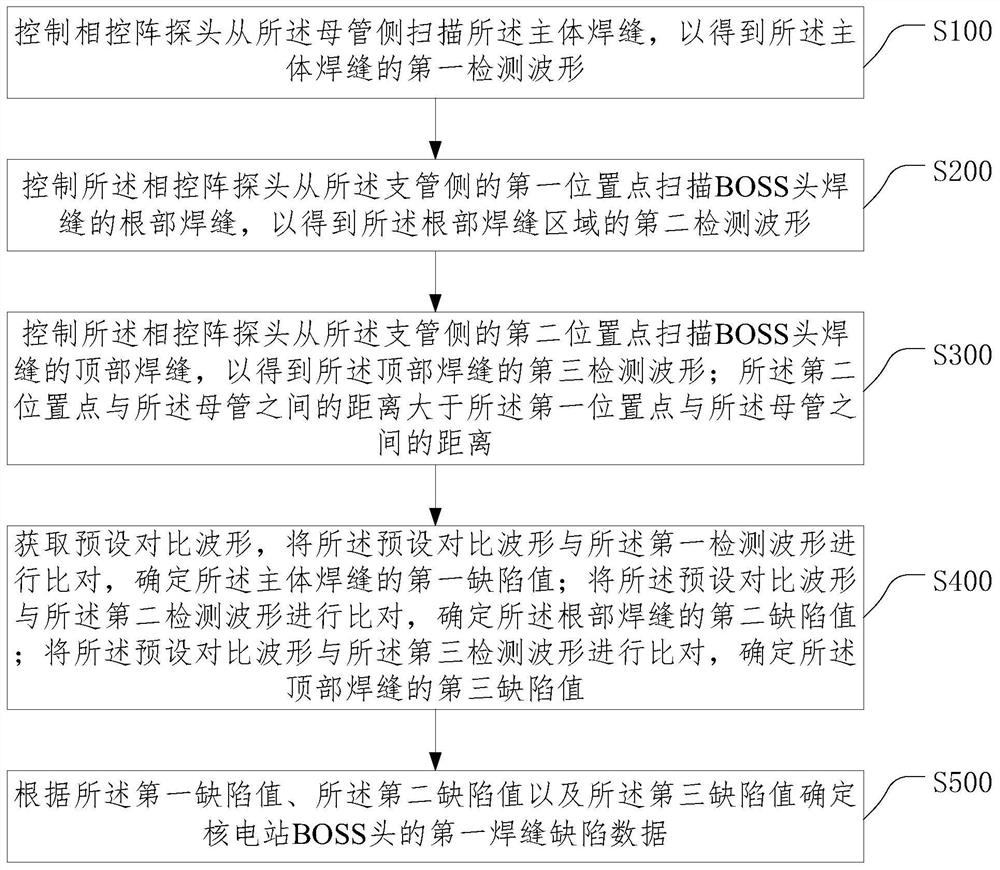

Nuclear power station BOSS head welding seam detection method, system, equipment and medium

PendingCN113624840AImprove detection accuracyEasy to repair weldingAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNuclear powerWeld seam

The invention belongs to the technical field of nuclear power station maintenance optimization, and particularly relates to a nuclear power station BOSS head welding seam detection method, system and equipment and a medium. The nuclear power station BOSS head welding seam detection method comprises the steps that a control array probe scans a main body welding seam from a mother pipe side to obtain a first detection waveform of the main body welding seam; a phased array probe scans a root weld of the BOSS head weld to obtain a second detection waveform of a root weld area; the phased array probe scans a top welding seam of the BOSS head welding seam to obtain a third detection waveform of the top welding seam; a preset comparison waveform is acquired, the preset comparison waveform is compared with the first detection waveform, and a first defect value of the main body welding seam is determined; the preset comparison waveform is compared with the second detection waveform, and a second defect value of the root welding seam is determined; and the preset comparison waveform is compared with the third detection waveform to determine a third defect value of the top welding seam. According to the nuclear power station BOSS head welding seam detection method, the detection precision of the nuclear power station BOSS head is improved.

Owner:LINGAO NUCLEAR POWER +4

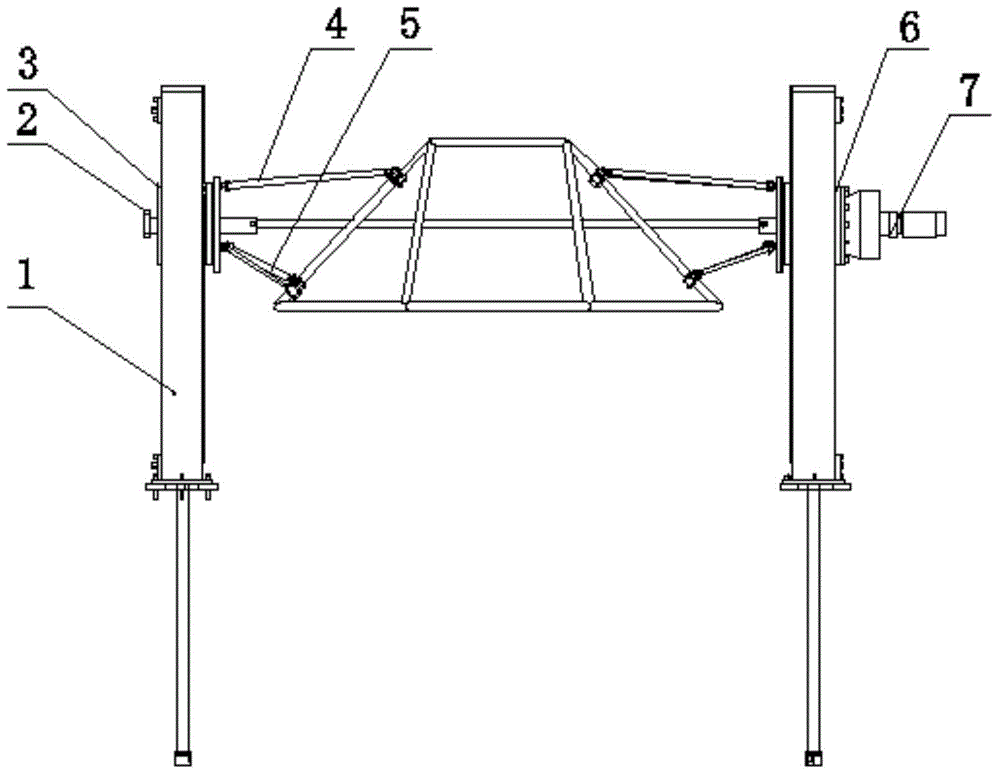

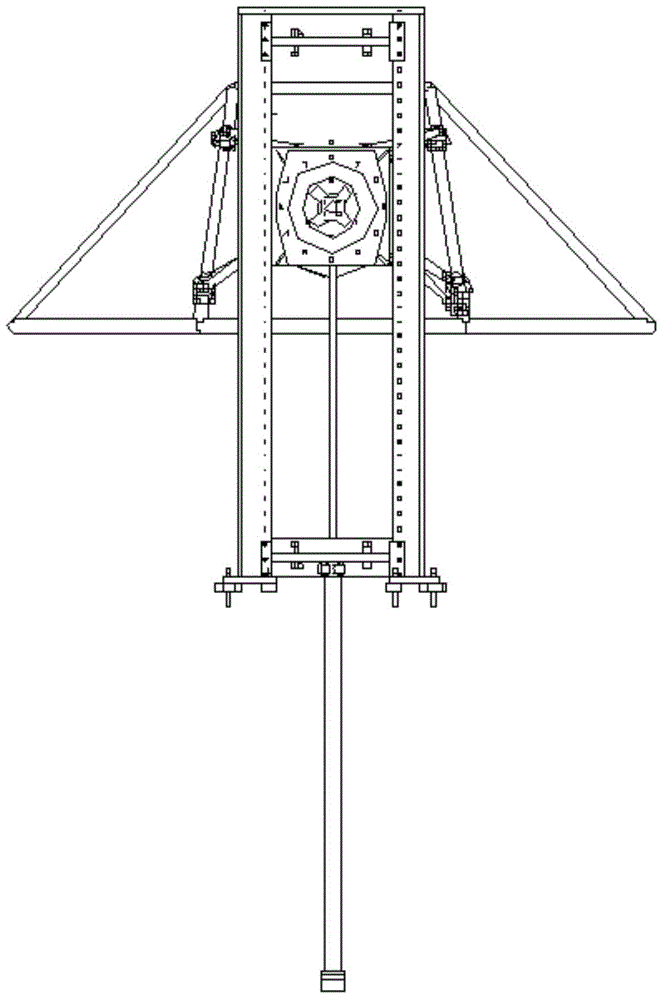

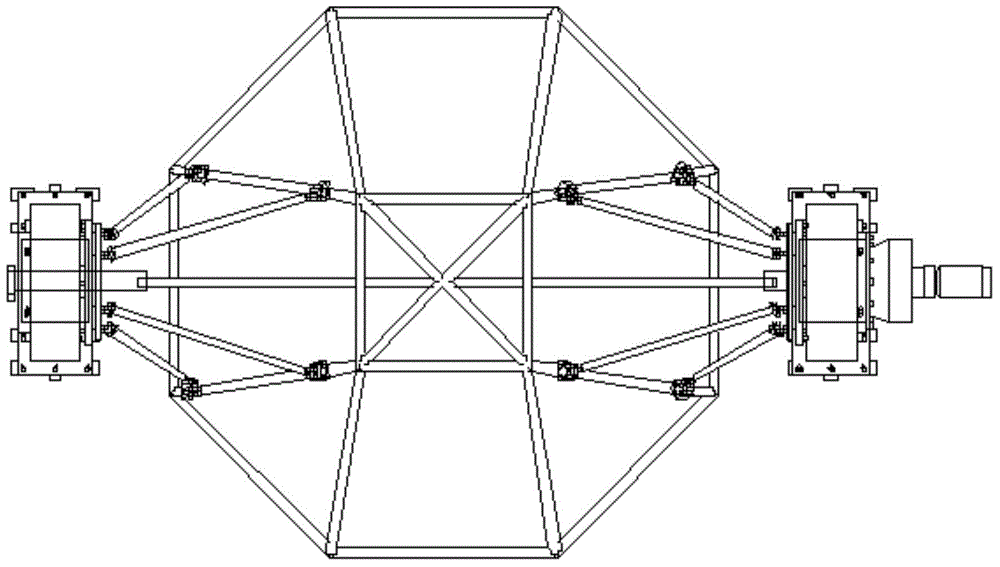

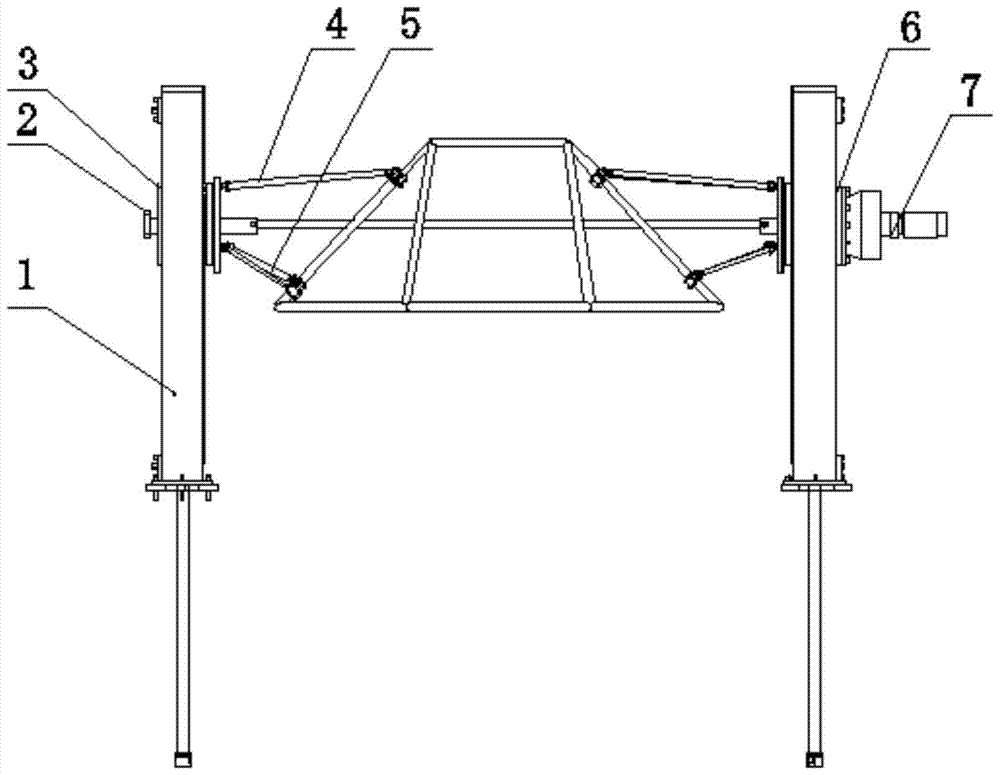

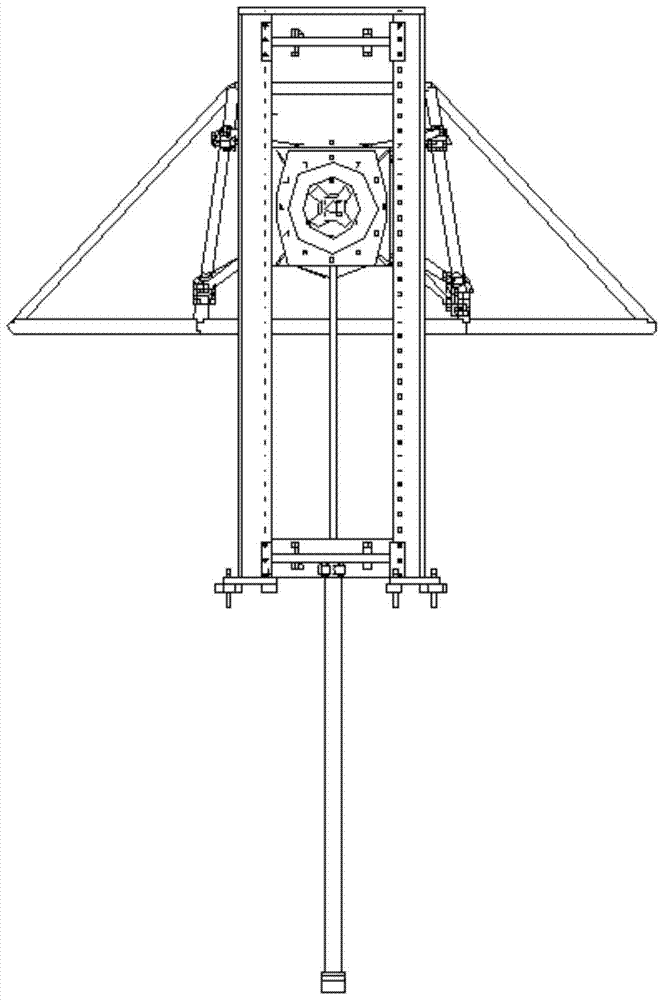

Timing position change device

ActiveCN104891401ARealize time-sensitive workRealize batch time-sensitive jobsLifting devicesHoisting equipmentsEngineeringSpeed reduction

The invention discloses a timing position change device. The timing position change device comprises portal assemblies arranged on the two sides, a left support assembly, a right support assembly, a linkage shaft assembly, a long connecting rod assembly, a short connecting rod assembly, and a speed reduction motor, wherein the left support assembly and the right support assembly are arranged on the portal assemblies, the linkage shaft assembly penetrates through the left support assembly and the right support assembly, the long connecting rod assembly and the short connecting rod assembly are connected with the left support assembly and the right support assembly, and the speed reduction motor is connected with the right support assembly. The timing position change device is simple in structure, can quickly clamp workpieces, overturn products and change the positions of products safely and rapidly, and production efficiency is greatly improved.

Owner:成都润博科技有限公司

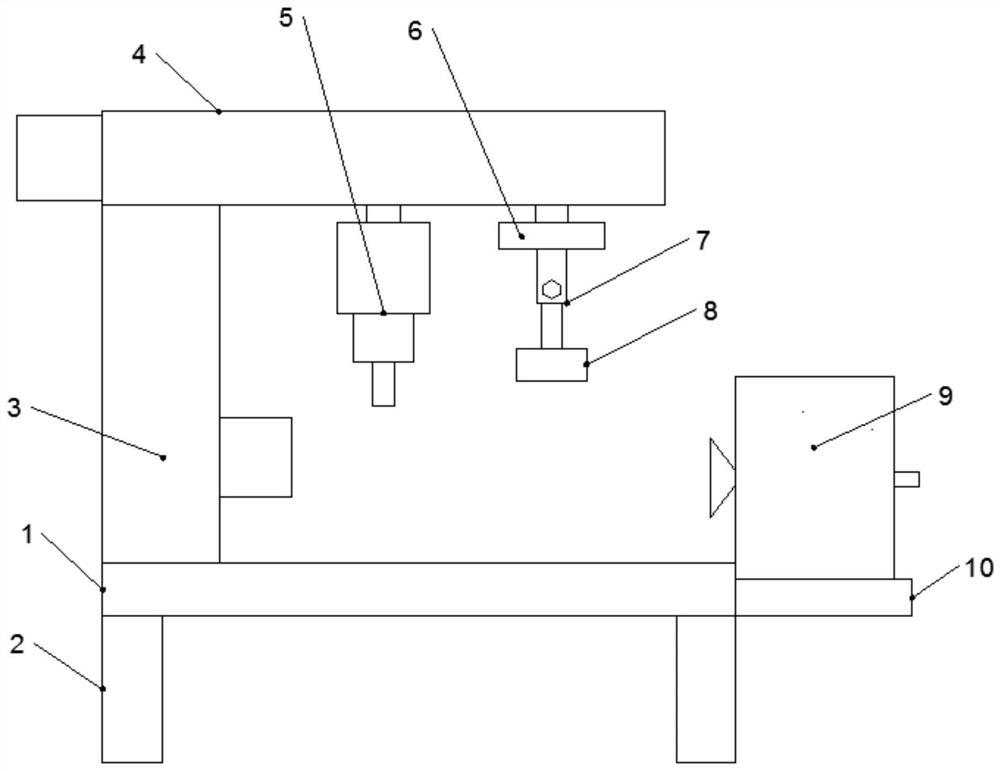

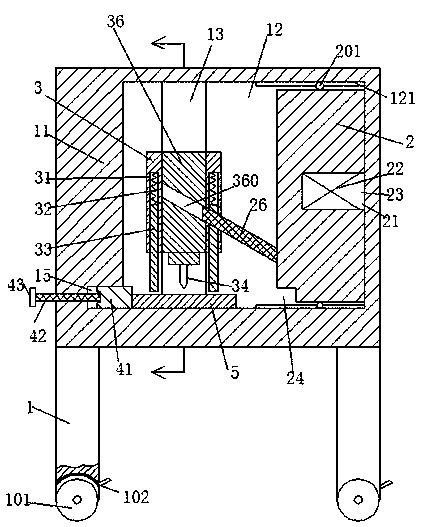

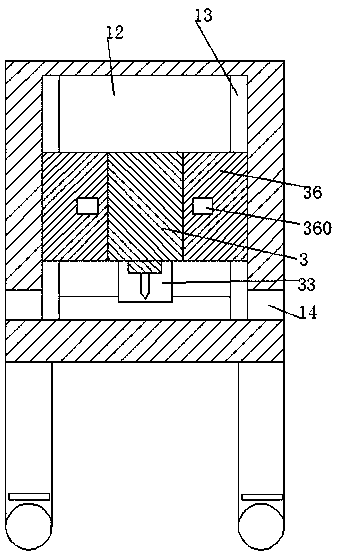

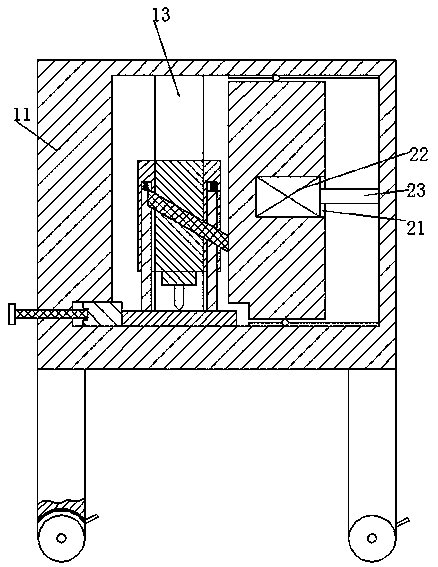

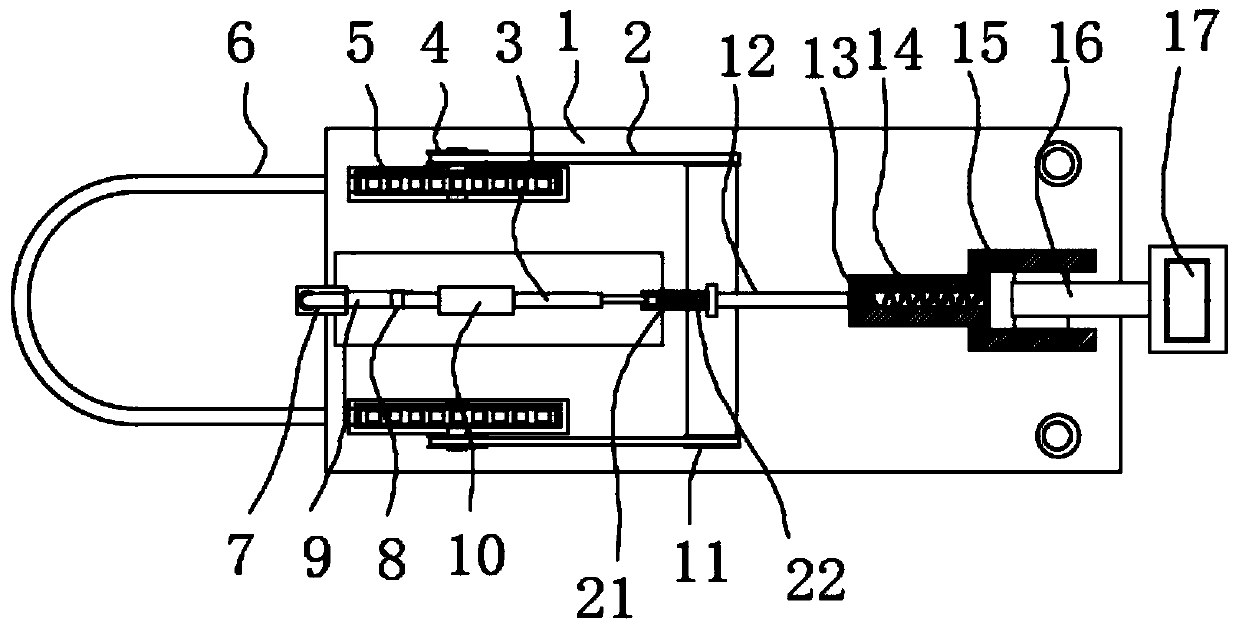

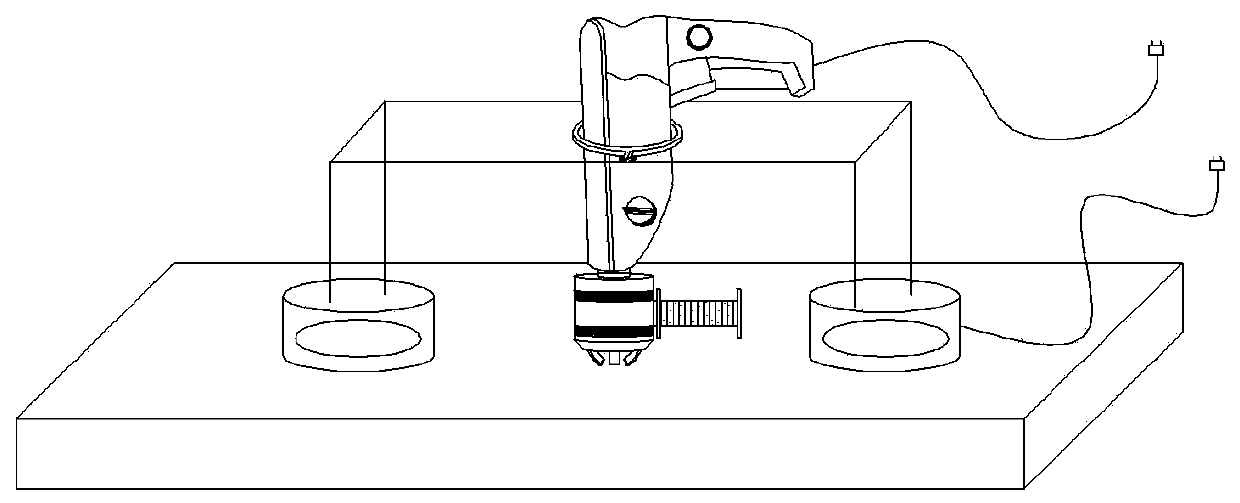

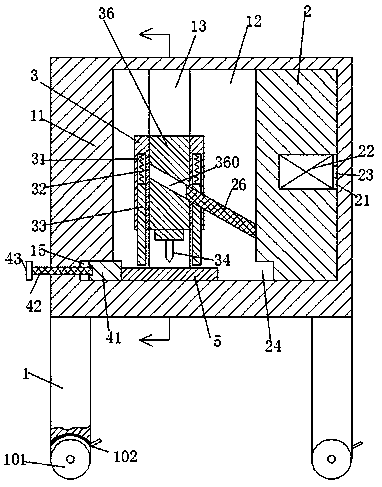

a welding device

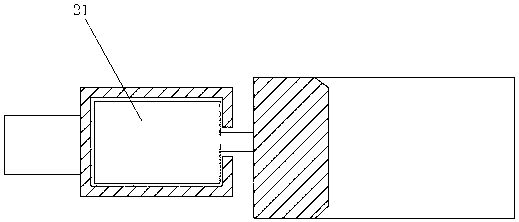

ActiveCN107414375BEasy to repair weldingEasy to determineWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention relates to a novel welding device, which comprises a welding frame, a welding box and a point welding machine, wherein the welding box is fixedly arranged at the upper end of the welding frame; rolling wheels are arranged at the bottom of the welding frame; a brake plate is arranged at the right side surface of the welding frame arranged above the rolling wheels; an accommodating cavity is formed in the welding box; ascending and descending grooves extending in the vertical direction are formed in the front and back inner walls of the accommodating cavity; sliding arms matched with the ascending and descending grooves are symmetrically arranged at the front part and the back part of the point welding machine; each sliding arm is provided with an inclined angle groove; the lower end of the point welding machine is provided with a welding head; retraction grooves with downward end openings are symmetrically formed in the point welding machine at the left side and the right side; a press block is arranged in each retraction groove in a way capable of vertically sliding; the upper end of each press block is fixedly provided with a tension spring; and the upper end of each tension spring is fixedly connected with the top wall of the corresponding retraction groove.

Owner:南昌江铃集团联成汽车零部件有限公司

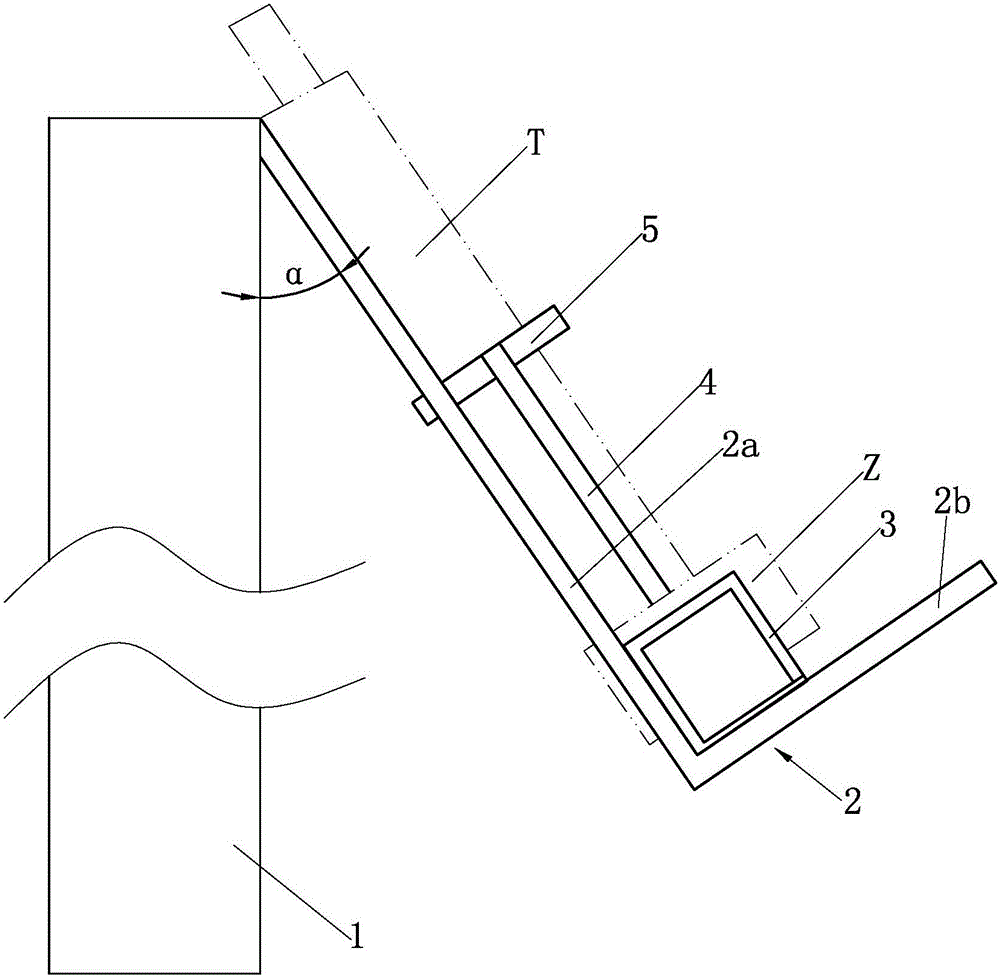

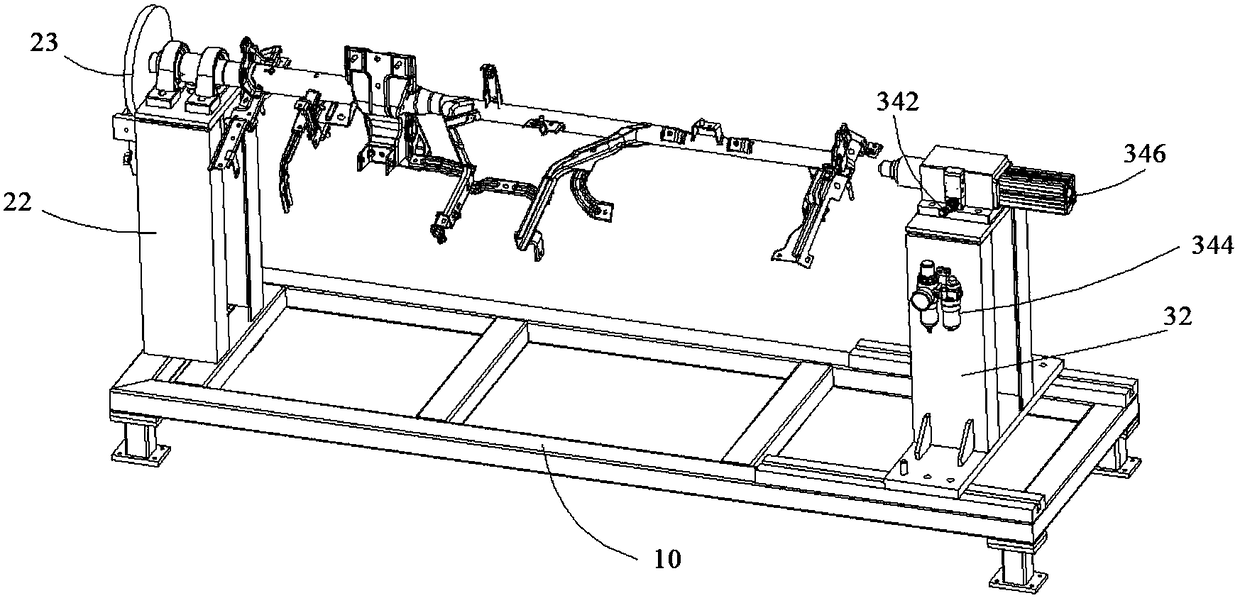

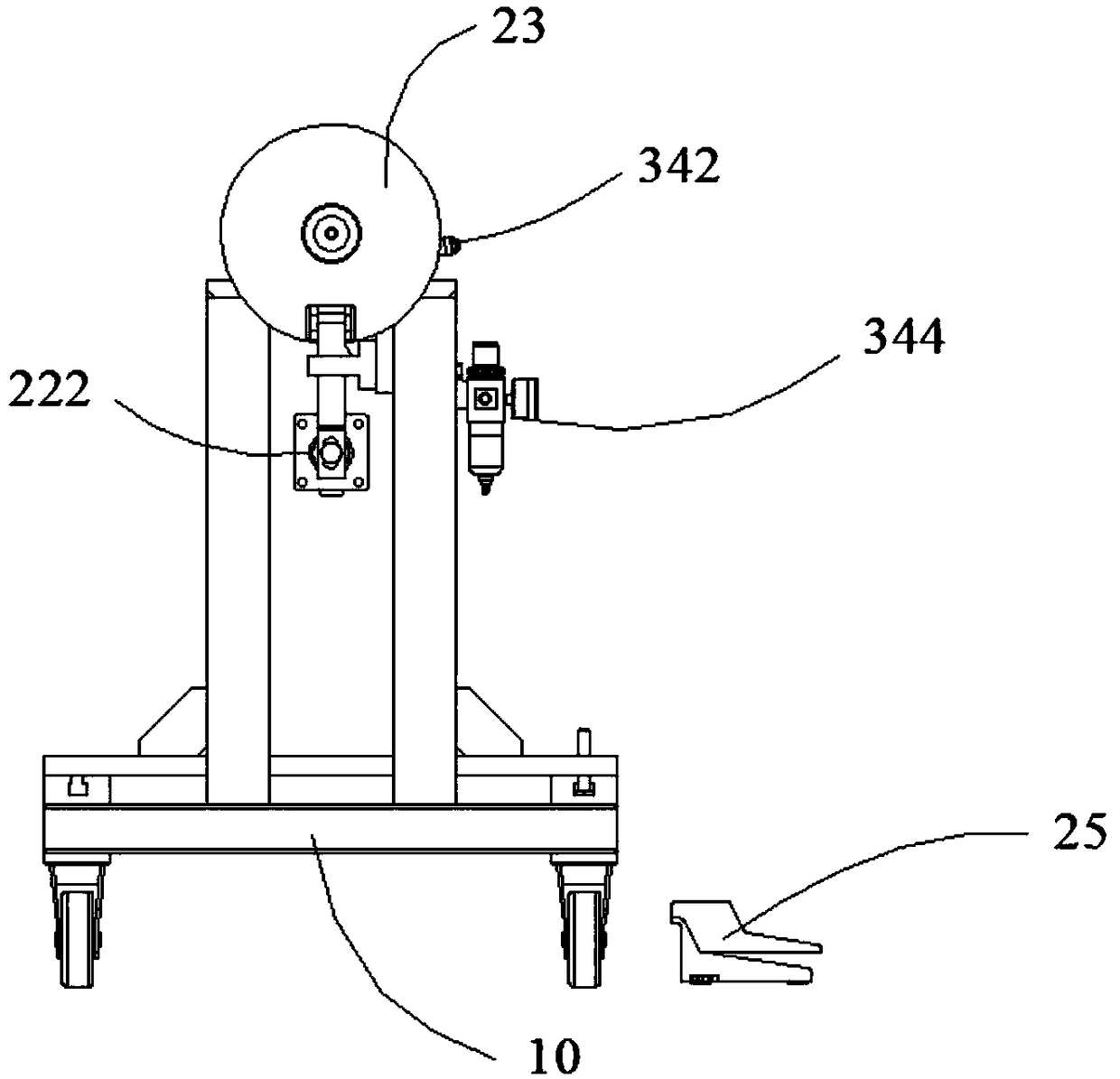

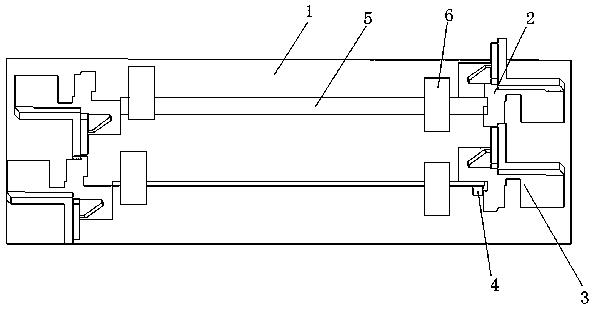

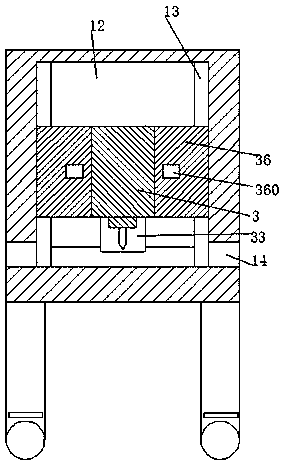

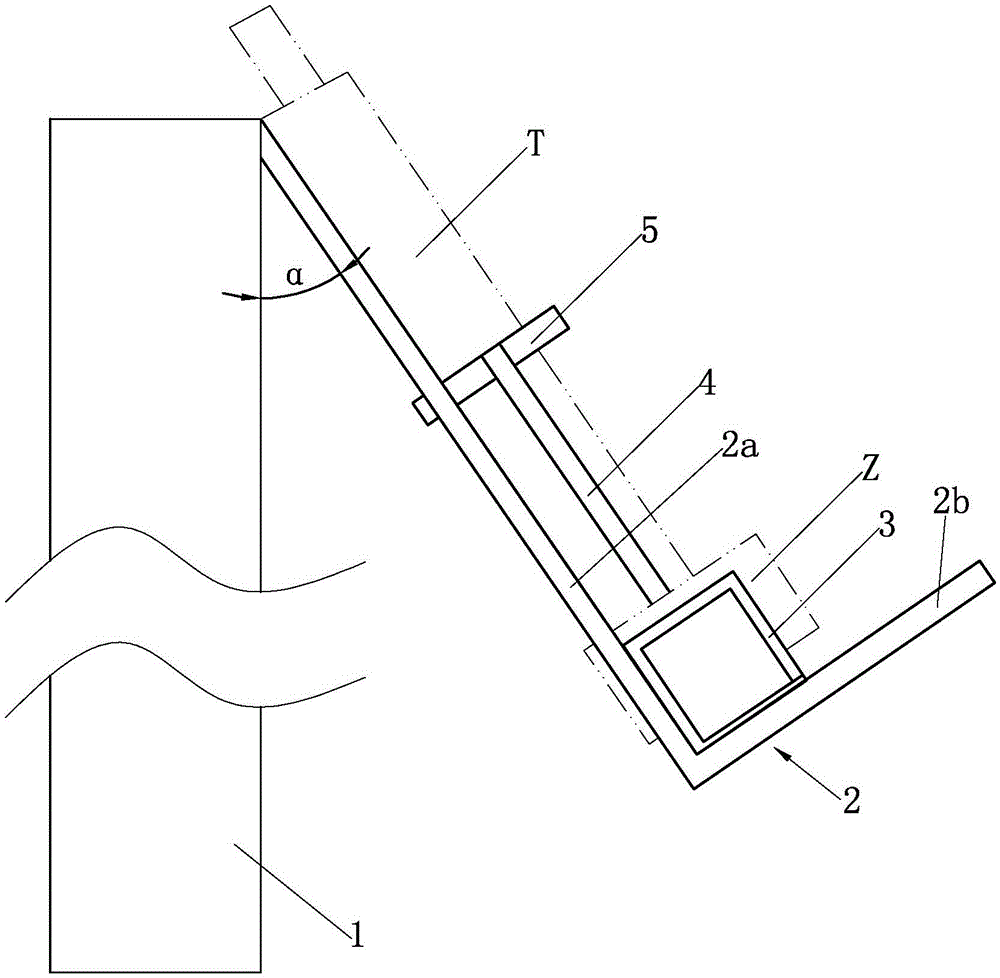

Welding fixture for rear lateral rod assembly

InactiveCN109590647AReasonable structural designEasy to make costWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses a welding fixture for a rear lateral rod assembly. The welding fixture comprises a fixture platform (1), welding locating mechanisms (2), repair welding locating mechanisms (3), pin removal mechanisms (4) and rear lateral rod welding assemblies (5); the welding locating mechanisms (2) are arranged on one side of the upper end of the fixture platform (1), and one side of each welding locating mechanism (2) is provided with the repair welding locating mechanisms (3) side by side; and the welding locating mechanisms (2) and the repair welding locating mechanisms (3) are each provided with the rear lateral rod welding assembly (5), and the pin removal mechanisms (4) are arranged below the ends of the welding locating mechanisms (2) and the repair welding locating mechanisms (3) in a fit manner. The welding fixture for the rear lateral rod assembly has the advantages of rational structural design, convenience and practicality, a good using effect and low manufacturing cost, and the number of maintenance is reduced; the maintenance cost is reduced, and simultaneous welding location and repair welding are facilitated; and the input of the welding fixture is reduced, and the working efficiency is improved.

Owner:WUHU POWER TECH

A time-shifting device

ActiveCN104891401BRealize time-sensitive workRealize batch time-sensitive jobsLifting devicesHoisting equipmentsEngineeringSpeed reduction

The invention discloses a timing position change device. The timing position change device comprises portal assemblies arranged on the two sides, a left support assembly, a right support assembly, a linkage shaft assembly, a long connecting rod assembly, a short connecting rod assembly, and a speed reduction motor, wherein the left support assembly and the right support assembly are arranged on the portal assemblies, the linkage shaft assembly penetrates through the left support assembly and the right support assembly, the long connecting rod assembly and the short connecting rod assembly are connected with the left support assembly and the right support assembly, and the speed reduction motor is connected with the right support assembly. The timing position change device is simple in structure, can quickly clamp workpieces, overturn products and change the positions of products safely and rapidly, and production efficiency is greatly improved.

Owner:成都润博科技有限公司

Weld joint detection device and method

PendingCN112525439AHigh speedTooling structure is simpleMeasurement of fluid loss/gain rateEngineeringStructural engineering

The invention provides a weld joint detection device and method, and relates to the technical field of weld joint detection, the weld joint detection device comprises a rack, a side sealing assembly,an air supply pressure measurement assembly and an upper sealing assembly, and a limiting block is arranged on the rack; the side sealing assembly is arranged on the side, away from the limiting block, of the rack and used for blocking a side opening of the weldment, and an air supply channel is formed in the side sealing assembly; the air supply pressure measurement assembly is connected to the side sealing assembly, and a pressure detection element is arranged on the air supply pressure measurement assembly; the upper sealing assembly is arranged on the rack, and the lower end is used for sealing an upper opening of the weldment. According to the weld joint detection device, the upper sealing assembly is used for blocking the upper opening of the weldment, the side sealing assembly is used for abutting against the side face of the weldment, air is supplied into the hole channel through the air supply pressure measurement assembly, and whether the weld joint leaks gas or not is accurately judged by detecting the pressure value in the hole channel; the welding quality of the weldment can be conveniently detected in the initial welding stage of a large component, the weld joint detection speed is increased, and repair welding can be conveniently conducted in time.

Owner:CRRC TANGSHAN CO LTD

A device capable of detecting the airtightness of an exhaust manifold and its application method

ActiveCN107884140BClosely connectedEasy to useVehicle testingDetection of fluid at leakage pointControl systemPipe fitting

The invention provides novel equipment capable of detecting exhaust manifold airtightness and an application method. The novel equipment comprises a detection vehicle, a starter, an alarm device and awater-gas three-way main pipe, wherein a plurality of vertical and transverse slideways are arranged on three sides of the detection vehicle, a plurality of clamping devices and a sealing device witha first claw stretch out from the inner portion of the vertical and transverse slideways, the clamping devices and the sealing device are respectively connected with a power device, a tail end of thepower device penetrates through the vertical and transverse slideways, the power device moves on the vertical and transverse slideways, the detection vehicle is provided with automatic water injection pipe fittings and automatic air transmission pipe fittings, the starter and the alarm device are arranged outside the detection vehicle and are connected with a control system through sensors, the water-gas three-way main pipe is provided with an exhaust manifold connection device and is further provided with two branch pipes, and the branch pipes are respectively connected with the automatic water injection pipe fittings and the automatic air transmission pipe fittings. The novel equipment is advantaged in that manifold airtightness is detected through compression water seepage, the detection effect is visual and obvious, and one machine multiple purposes is realized.

Owner:东兴市思丰海产品实业有限公司

River point welding auxiliary device

InactiveCN111468870AEasy to repair weldingUse environmental protection and scienceWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringStructural engineering

The invention discloses a river point welding auxiliary device which comprises a base with the transverse cross section shaped like a Chinese character 'ao'. A transversely-arranged limiting groove isformed in the base. A first spring is fixedly connected to one side wall of the limiting groove. A movable sleeve is fixedly connected to one end of the first spring. A positioning pin is inserted into the movable sleeve. A Y-shaped block is fixedly connected to one side of the positioning pin. A driving device is arranged on the Y-shaped block. Due to the mutual effect of a corrugated pipe, a point welding pipe and other structures, when a column just makes contact with a beam, preliminary welding is achieved, workers can achieve follow-up repair welding, the device relies on river as motivepower, and use is more environmentally friendly and scientific.

Owner:周兵

Welding, positioning and flaw detection method for automobile muffling pipe

InactiveCN104807965AExtended service lifeEasy to repair weldingMaterial analysisSolid structureEngineering

The invention discloses a welding, positioning and flaw detection method for an automobile muffling pipe. The welding, positioning and flaw detection method comprises the following steps: a main body part of an outer pipe is arranged in a filling cavity, and the two ends of the outer pipe are fastened by fixing rings; two separation plates are respectively attached to the outer walls of the upper side and the lower side of the outer pipe, and the movable ends of the two half barrel bodies are fixedly connected; gypsum slurry is injected into an injection hole until the gypsum slurry completely fills the filling cavity; the end part of the outer pipe fastened by the fixing ring is connected with an air pipe, and compressed air is injected into the outer pipe through the air pipe; under the jetting action of the compressed air, obvious recess traces are retained on a semisolid structure; the compressed air is continuously fed until the gypsum slurry is completely converted into a solid structure, and air feeding is stopped; the filling cavity is opened to separate the formed gypsum solid structure from the outer pipe and the inner walls of the half barrel bodies respectively; after an independent gypsum fixing structure is obtained, the size of an arc-shaped inner wall recess is observed, so that a crack position, corresponding to the outer pipe, of a welding line can be obtained.

Owner:CHENGDU LINGCHUAN SPECIAL IND

Sampling device and sampling method

PendingCN110261163ASimple structureEasy to operateWithdrawing sample devicesEngineeringMilling cutter

The invention relates to a sampling device and a sampling method. The sampling device includes a sampling machine and a fixing rack; the sampling machine includes a sampling head and a rotary driving mechanism; the rotary driving mechanism is arranged on the fixing rack; and the fixing rack is arranged on a connecting mechanism used for fixedly connecting with a to-be-sampled component; the sampling head includes a threaded seat, a rotating seat and a milling cutter; the rotating seat is in transmission connection with the rotary driving mechanism; the milling cutter is arranged in the guiding groove of the rotating seat; the threaded seat is provided with a conical surface; the milling cutter surface is provided with a tooth pattern section; and the tooth pattern section meshes with the thread of the conical surface to form a screw-pair structure of a leading screw. The fixing rack can stably fix the sampling machine on the component; a cutting edge can perform telescoping and moving when rotating around a rotating shaft; and thus, micro-damage sampling can be realized, and the device and method have advantages of being simple in structure, convenient in operation, good in stability, flat in sampled part and easy in welding and repairing after taking.

Owner:国能神福(晋江)热电有限公司 +2

a welding device

ActiveCN107009013BEasy to repair weldingEasy to determineResistance electrode holdersWelding/cutting auxillary devicesEngineeringBilateral symmetry

A welding device comprises a welding rack and a welding box fixedly mounted at the upper end of the welding rack, as well as a spot welder, wherein rollers are arranged at the bottom of the welding rack; a braking vane is arranged on the right side surface, above each roller, of the welding rack; an accommodating cavity is formed in the welding box; lifting grooves stretching up and down are arranged in the front inner wall and the rear inner wall of the accommodating cavity; sliding arms matched with the lifting grooves are symmetrically arranged on the spot welder in tandem; each sliding arm is provided with an oblique groove; a welding head is mounted at the lower end of the spot welder; indentation grooves of which end openings face downwards are formed in the spot welder in bilateral symmetry; a pressing block capable of sliding up and down is arranged in each indentation groove; a tension spring is fixedly mounted at the upper end of each pressing block; and the upper ends of the tension spring are fixedly connected with the top walls of the corresponding indentation grooves.

Owner:CHONGQING ENDURANCE ZHONG YI SHOCK ABSORBER LIABILITY

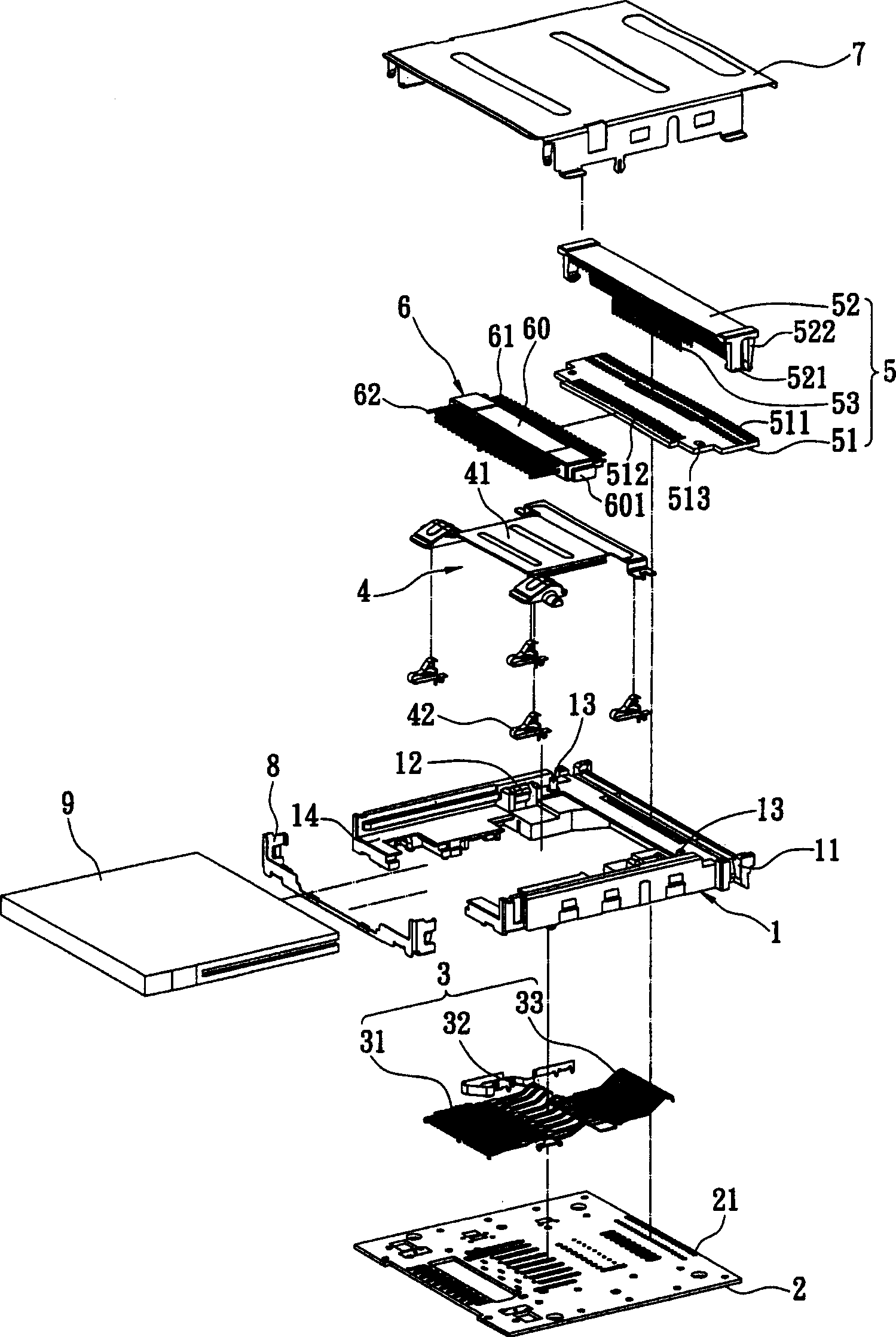

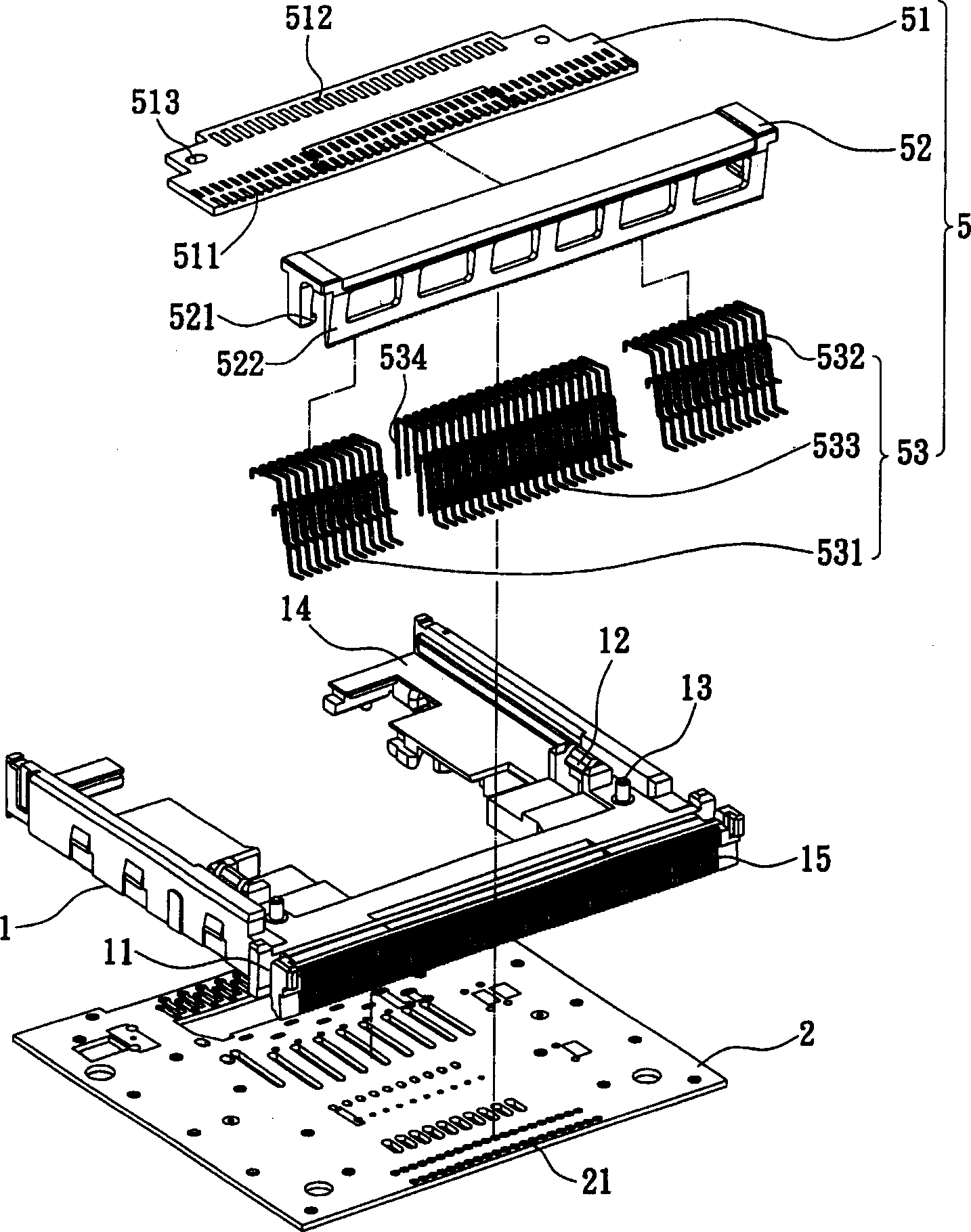

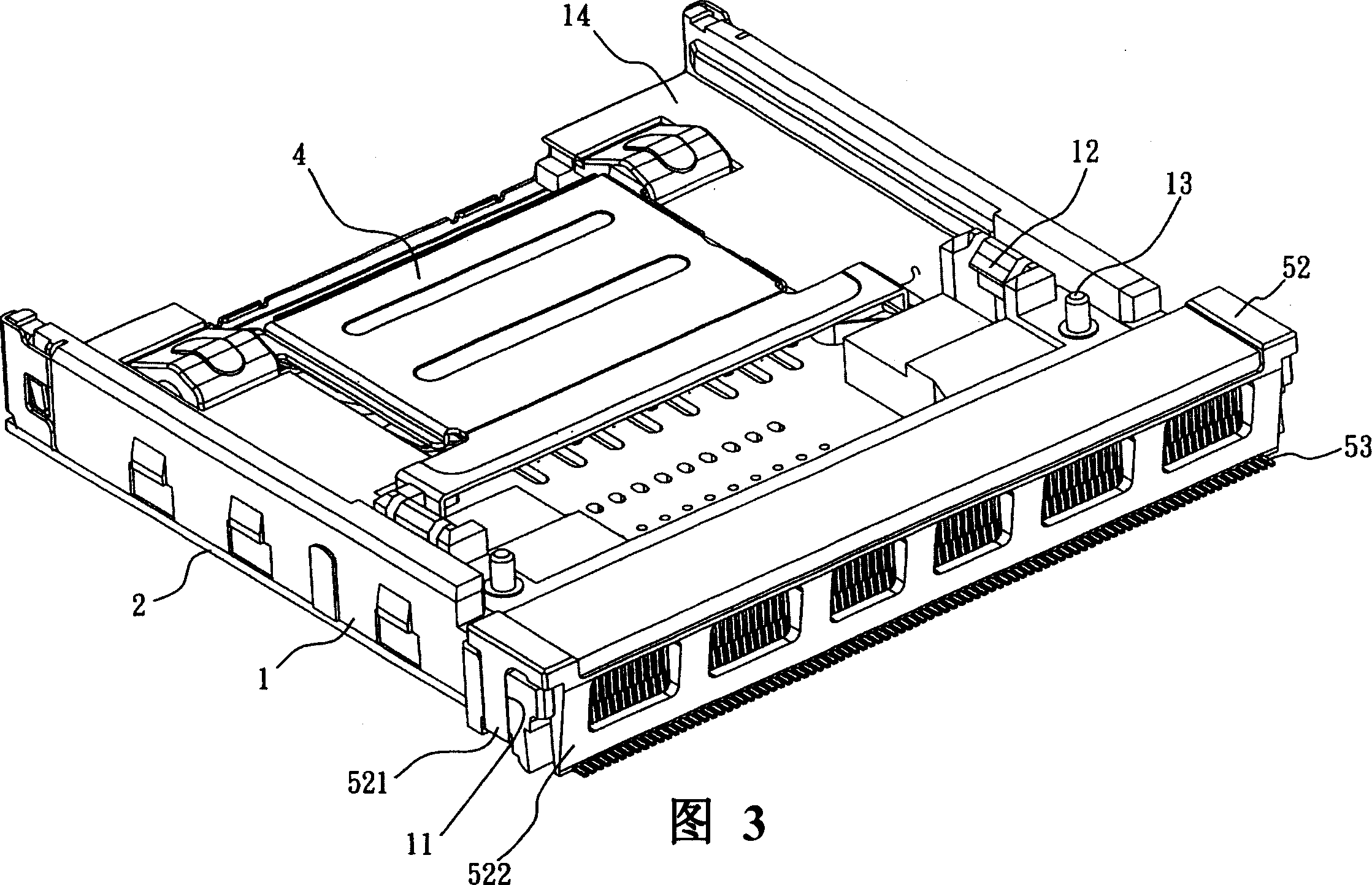

Card connector

InactiveCN1719665AEasy to replaceImprove flatnessTwo-part coupling devicesFixed connectionsBody positionsElectrical and Electronics engineering

This invention relates to a card pin-contact device including an insulation body with a CB at the bottom side, multiple terminal sets electrically connected on said CB, a connection module including a body positioned on said insulation body, multiple contact terminals and conduction terminals opposite to said body and a transfer unit including a transfer terminal group, a pressing piece positioned on said insulation body to further press on said transfer terminal set and a transfer component positioned on said insulation body and connected with part of the abutting ends of the transfer terminal group and the module, the abutting ends of other part of the transfer terminal group are connected with the welding part of the CB by the transfer piece.

Owner:JESS-LINK PRODUCTS

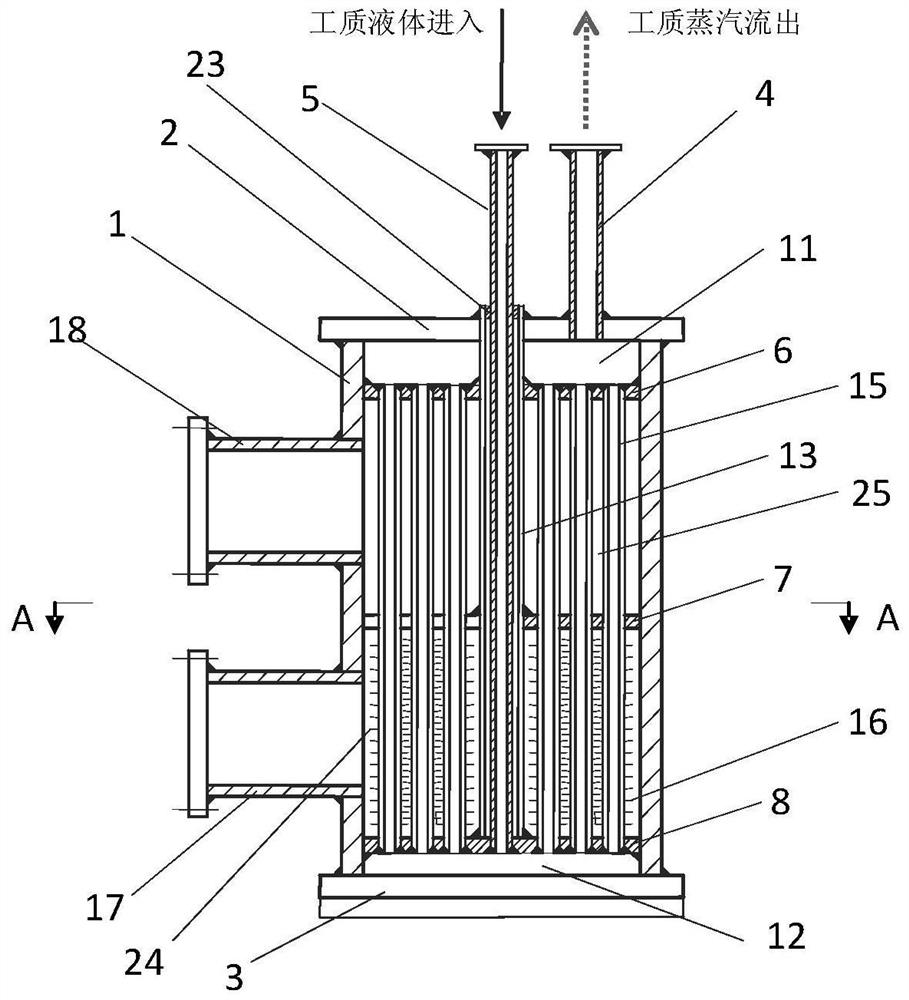

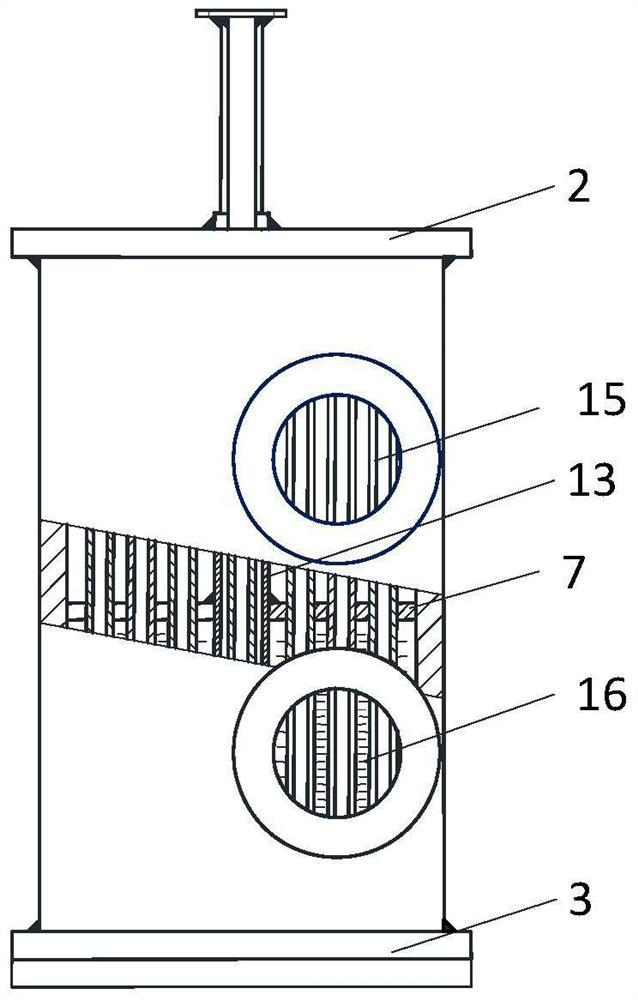

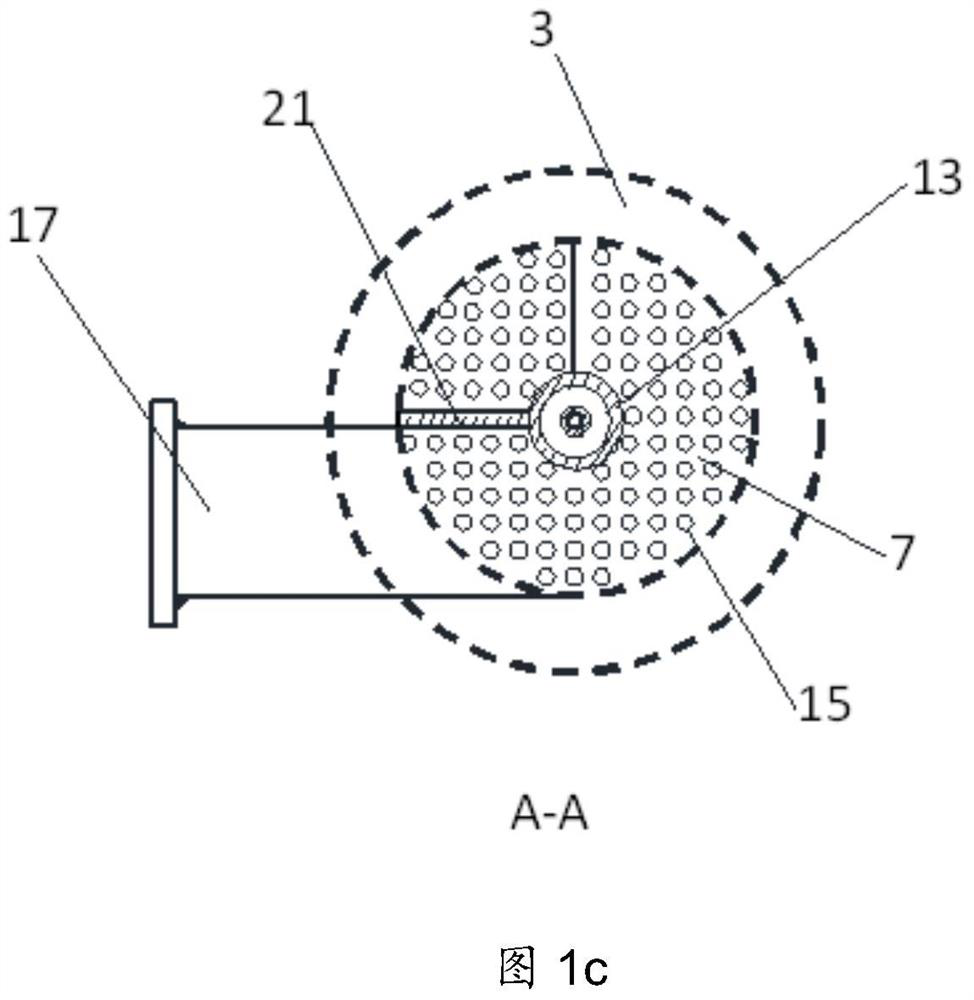

A separate heat pipe evaporator heated by rotating flow

ActiveCN106091759BEliminate retentionSufficient heat exchangeEvaporators/condensersIndirect heat exchangersEngineeringHeat transfer fluid

The invention relates to a separated heat pipe evaporator heated by rotating flow. Two or more heat exchange fluid passages are formed by using partition plates in the heat exchange fluid. Circumferential circulation in each zone, the circumferential circulation of different channels passes through the openings on the baffles in the heat exchange fluid for axial flow connection, the fluid flow has no dead zone retention, and completely eliminates the baffles when the traditional Zigzag baffle structure is used for flow. The stagnation of the corner area makes the heat exchange sufficient and the resistance smaller; the liquid pipe and the steam outlet pipe are arranged on the top of the shell, and the liquid pipe passes through the shell to communicate with the liquid chamber at the bottom, and the outer wall of the liquid pipe is set with an isolation pipe. The structural design makes the central liquid inlet pipe pass through the central isolation pipe without being heated, and the return liquid will not be heated to generate steam to block the liquid return flow, and the return liquid of the present invention is more concentrated and uniform, and the filling volume of the working medium is greatly reduced , The structure of the evaporator is more compact and miniaturized.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Repair welding tool for oil storage cylinder assembly

InactiveCN105057948BEasy to repair weldingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a repair welding tool for an oil storage barrel assembly. Two right-angled rods are arranged on the left side and the right side of the front portion of a welding table side by side. Each right-angled rod is composed of a first circular rod and a second circular rod. The upper ends of the first circular rods are welded to the front portion of the welding table. The first circular rods are arranged forwards. The lower ends of the first circular rods and the lower ends of the second circular rods are perpendicularly fixed. The upper ends of the second circular rods are suspended. Circular rods are arranged on the left side and the right side of the top face of supporting square steel side by side and perpendicular to the top face of the supporting square steel; a rectangular frame is arranged between the two circular rods; and the upper ends of the two circular rods are perpendicularly fixed to frame bars at the left end and the right end of the rectangular frame respectively. By the adoption of the repair welding tool, repair welding can be conveniently and rapidly performed on the oil storage barrel assembly, so that circumferential welding between an oil storage barrel in the oil storage barrel assembly and an n-shaped supporting lug is achieved, and insufficient welding is avoided.

Owner:重庆川东减震制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com