Welding fixture for rear lateral rod assembly

A welding jig and thrust rod technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of one more pick and place, the total length of the welding seam is not too much, the cost of inputting more fixtures and maintenance management costs and other problems, to achieve the effect of convenient welding positioning and repair welding, low manufacturing cost and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

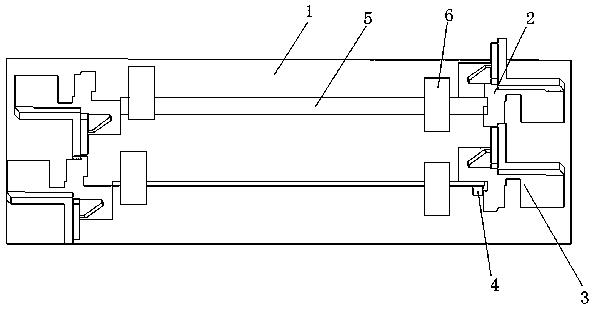

[0015] Such as figure 1 As shown, a rear transverse thrust rod assembly welding fixture, the welding fixture includes a fixture platform 1, a welding positioning mechanism 2, a repair welding positioning mechanism 3, a cancellation mechanism 4 and a rear transverse thrust rod welding assembly 5, the welding The positioning mechanism 2 is arranged on one side of the upper end of the fixture platform 1, and a repair welding positioning mechanism 3 is arranged side by side on the side of the welding positioning mechanism 2, and the welding positioning mechanism 2 and the repair welding positioning mechanism 3 are both provided with rear transverse thrust rod welding Assemblies 5, under the ends of the welding positioning mechanism 2 and the repair welding positioning mechanism 3, a canceling mechanism 4 is adaptively arranged.

[0016] The rear transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com