Repair welding method for deep groove of blade casting

A deep groove, repair welding technology, used in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of coarse grains and large deformation of parts, and achieve the suppression of grain growth, the concentration of arc capacity, and the reduction of heat. Enter low effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

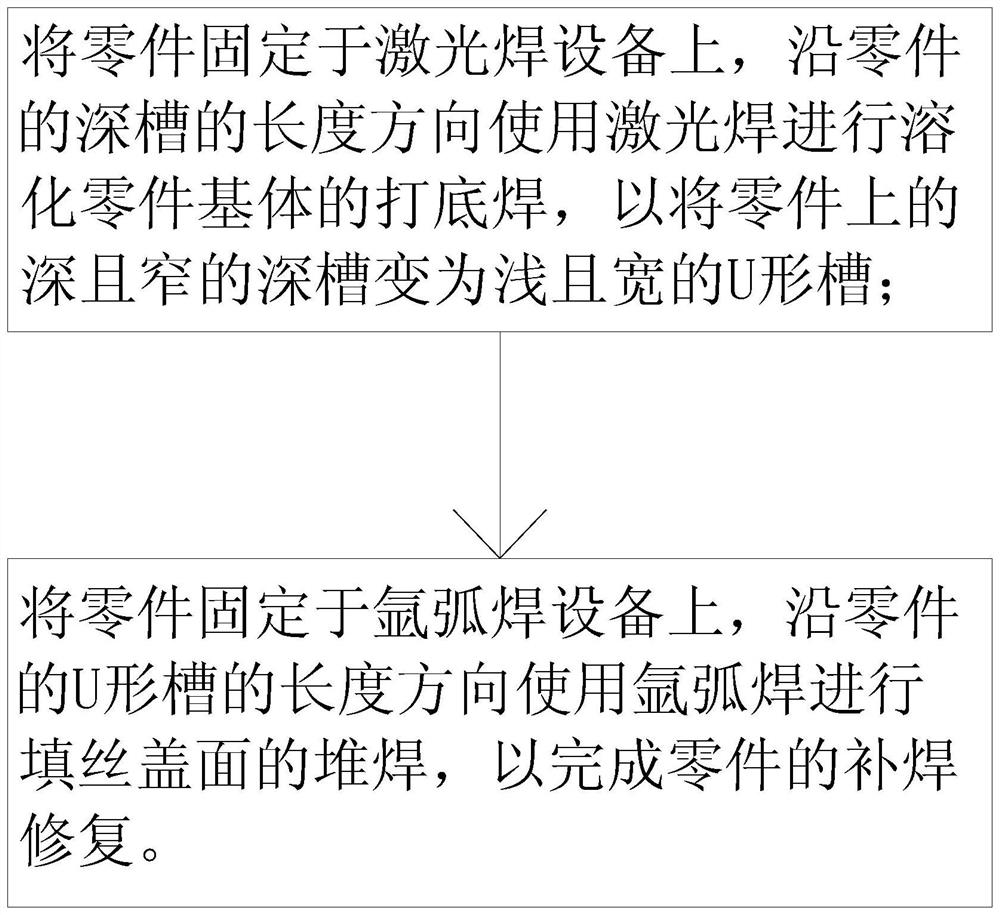

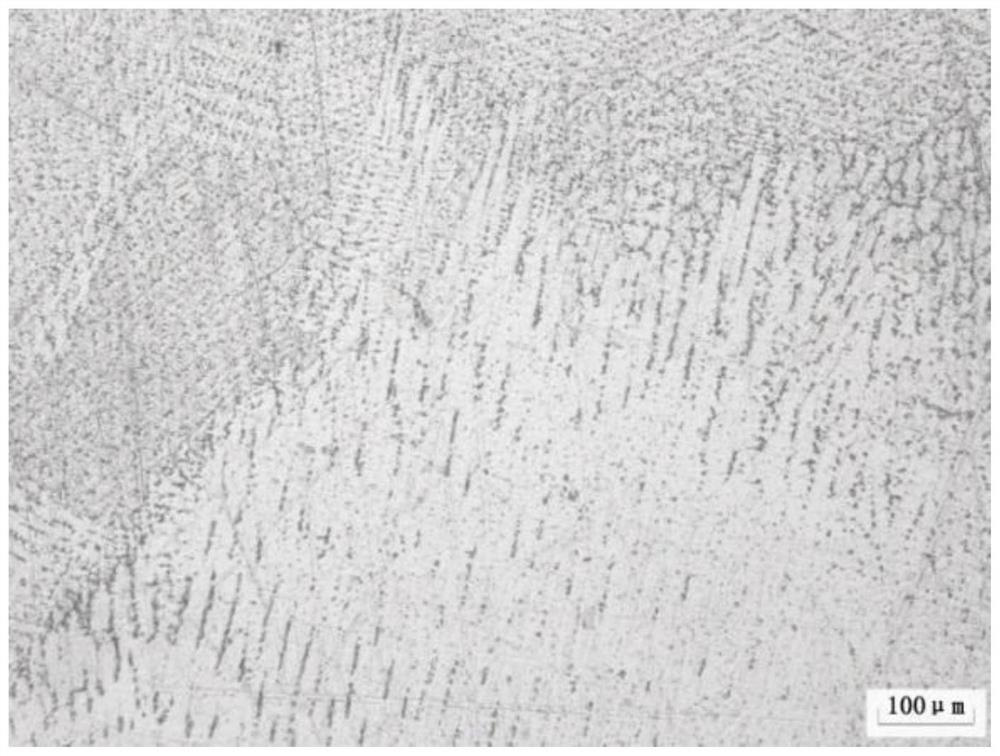

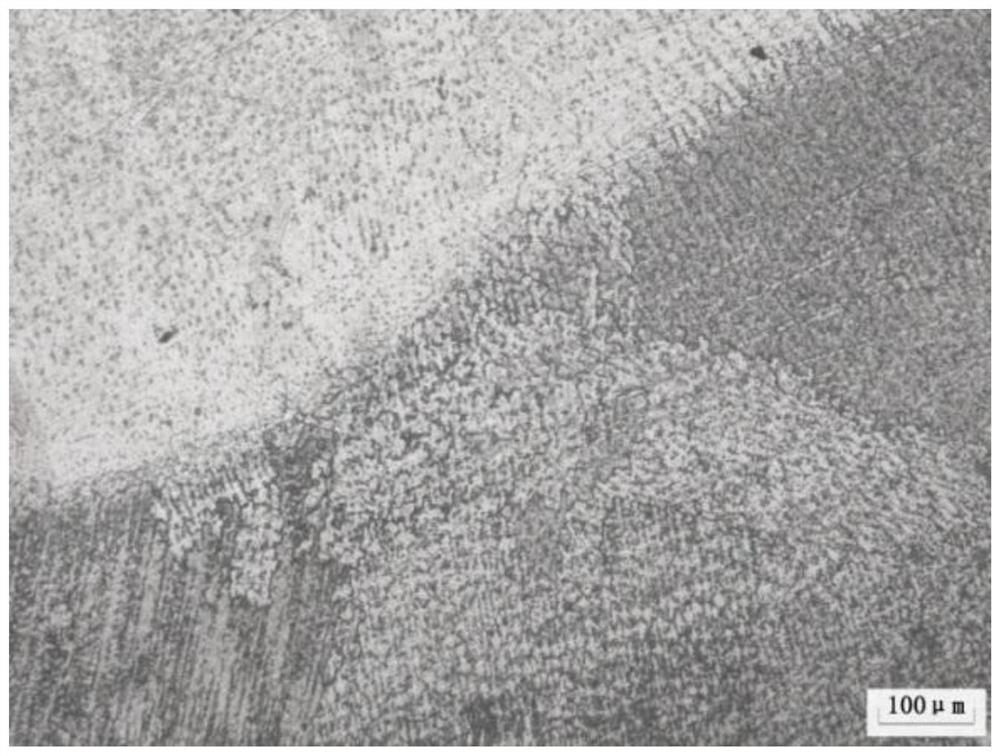

[0024] figure 1 It is a block diagram of the steps of the repair welding method for the deep groove of the blade casting in the preferred embodiment of the present invention; figure 2 It is the metallographic cut-away view of the welding seam of the blade casting deep groove repair welding method in the preferred embodiment of the present invention; image 3 It is the metallographic section diagram of the fusion line of the blade casting deep groove repair welding method in the preferred embodiment of the present invention; Figure 4 It is the metallographic cut-away view of the heat-affected zone of the substrate in the repair welding method for the deep groove of the blade casting in the preferred embodiment of the present invention.

[0025] Such as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com