High-temperature-resistant horizontal multi-layer gas inlet device for SiC epitaxy

An air inlet device, high temperature resistant technology, applied in the direction of chemical reactive gas, crystal growth, single crystal growth, etc., can solve problems such as undetectable, equipment damage, process room explosion, etc., to facilitate maintenance, improve reliability, The effect of convenient repair welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

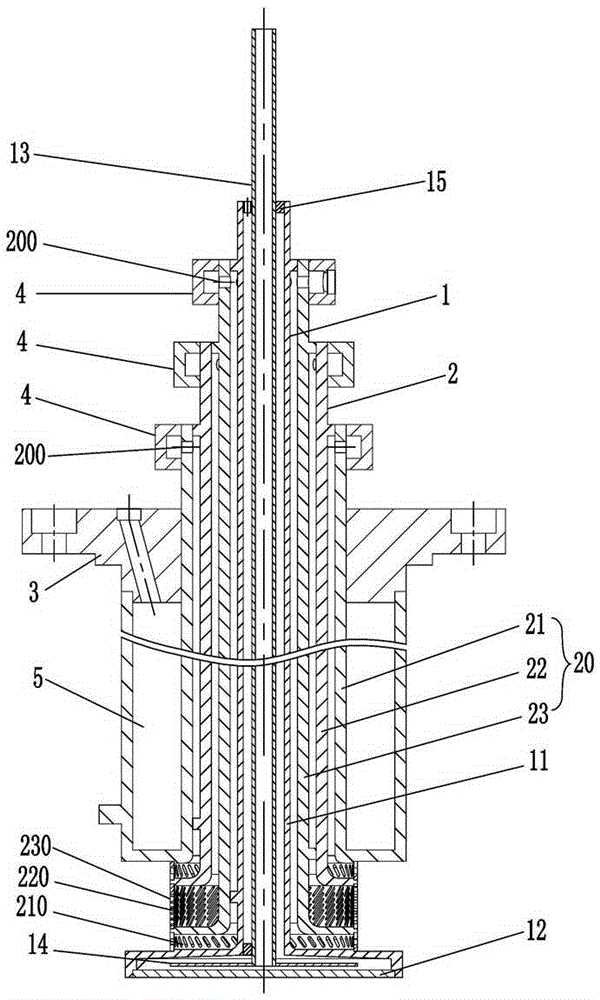

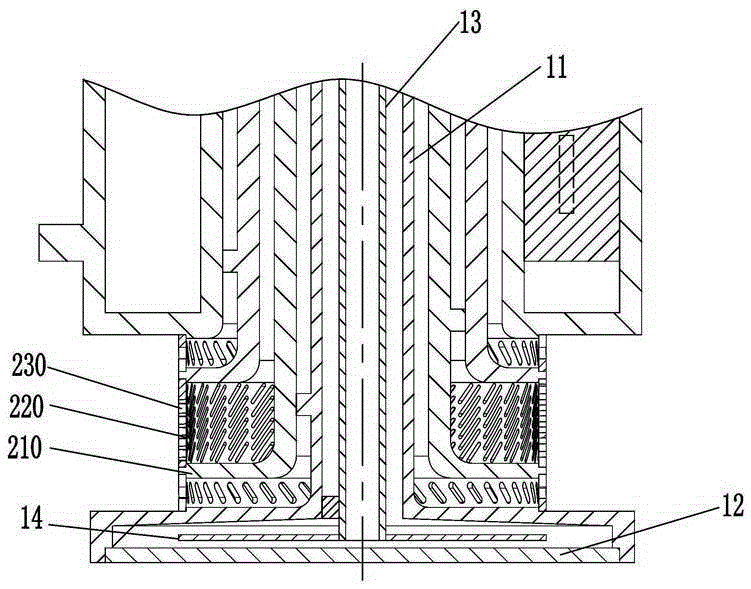

[0022] figure 1 It shows a high-temperature-resistant horizontal multi-layer air intake device for SiC epitaxy of the present invention, including an inner water jacket assembly 1, an air intake assembly 2, and a mounting flange 3 that are coaxially sleeved sequentially from the inside to the outside. The air intake assembly 2 includes multi-layer air intake rings 20 set coaxially at intervals. The multi-layer air intake rings 20 are elongated layer by layer from the outside to the inside. The top of each air intake ring 20 is provided with an air inlet 200, and the end is along the The folded surface 210 is folded radially outward to form a bell mouth shape. The folded surfaces 210 of the multi-layer intake ring 20 are arranged parallel to each other. direction, and the multi-layer intake ring 20 is corresponding to multi-layer parallel laminar flow gas ejection. The high-temperature process gas enters the intake assembly 2 from the air inlet 200, and the periphery of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com