Sampling machine

A sampling machine and sampling head technology, applied in the field of sampling machines, can solve the problems of poor stability, complex structure, difficult adaptation of alloy materials, etc., and achieve the effects of flattening the sampled part, easy welding and repairing, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

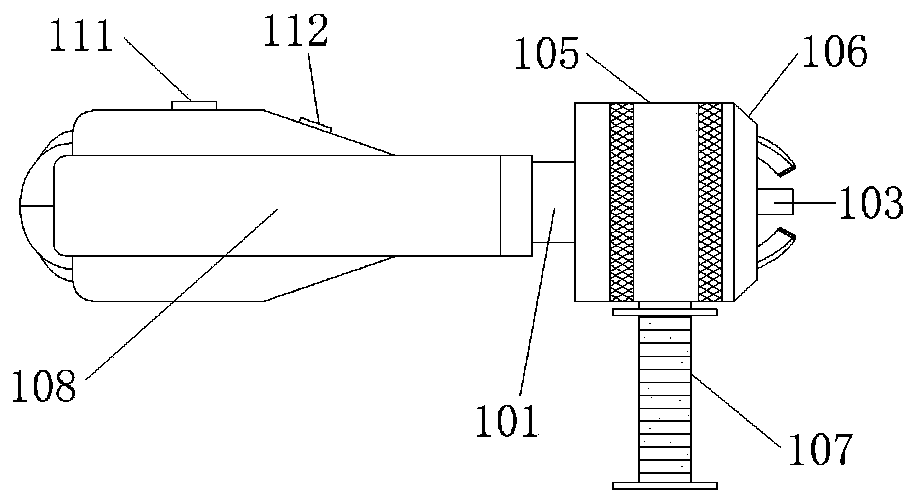

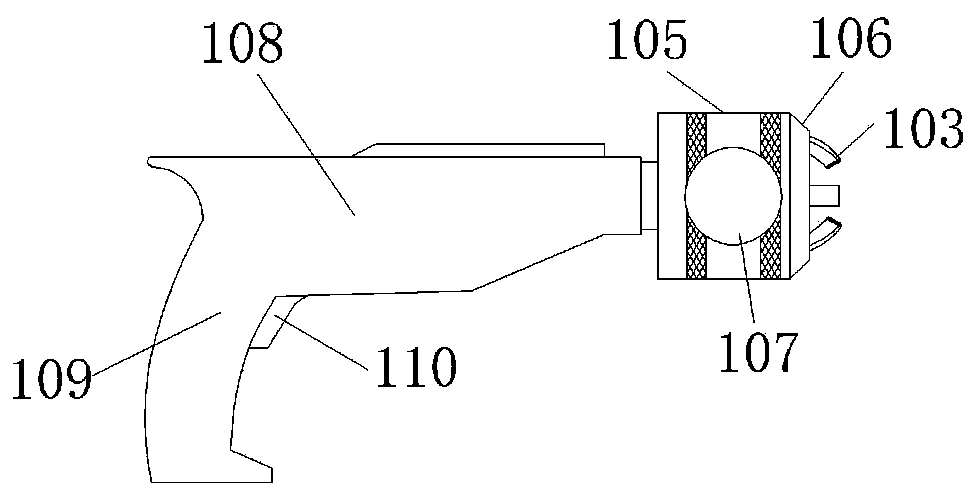

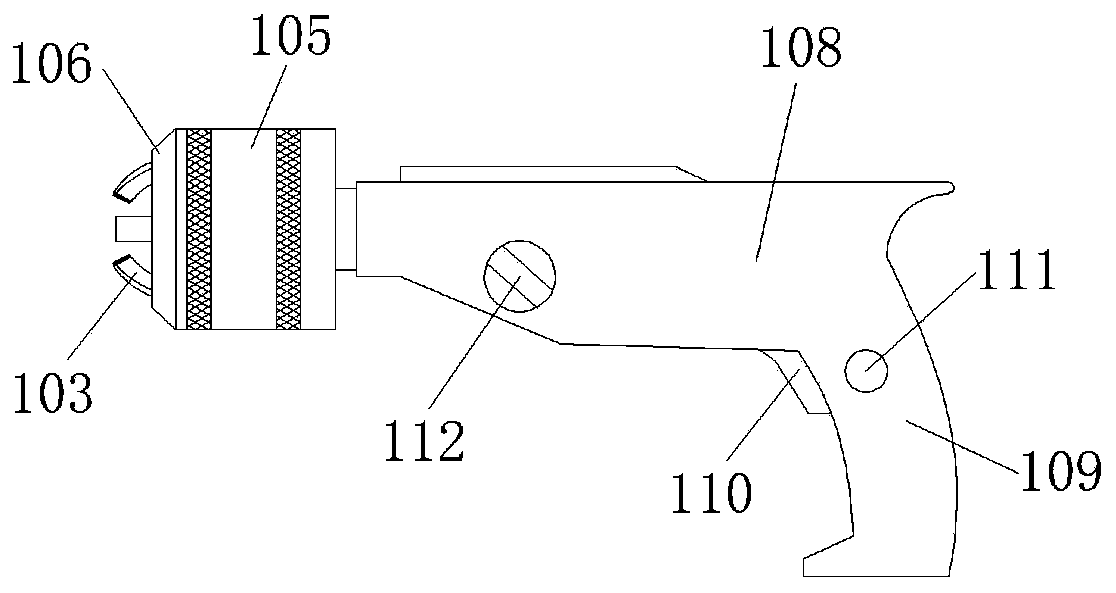

[0033] This embodiment provides a sampling machine, such as Figure 1-Figure 5 As shown, it includes a sampling head; the sampling head includes a threaded seat, a rotating seat 102 and a milling cutter 103; the rotating seat 102 is provided with a guide groove corresponding to the milling cutter 103; side; the end of the milling cutter 103 is provided with a blade 116, and the end is facing the axis of rotation; the end of the milling cutter 103 away from the end is the tail end, and the tail end is away from the axis of rotation; The axis of rotation has an included angle; the rotating seat 102 controls the rotation of the milling cutter 103 around the axis of rotation, and the threaded seat is provided with a tapered surface that matches the curved surface of the milling cutter 103; the tapered surface is provided with threads, and the milling cutter 103 faces the tapered One side of the surface is provided with a toothed section 115; the milling cutter 103 rotates along th...

Embodiment 2

[0047] This embodiment provides another structure of the threaded seat, such as Figure 9 As shown, it includes an inverted fixed seat 119, a round platform 117 and a fixed connecting rod 118; the side of the round platform 117 forms a tapered surface, and the thread is arranged on the side of the round platform 117 to form an external thread structure; the side of the milling cutter 103 facing the rotating shaft For the inner side, the tooth pattern segment 115 is arranged on the inner side of the milling cutter 103; the round table 117 and the milling cutter 103 are located on the same side of the rotating seat 102, and the round table 117 is located on the inner side of the milling cutter 103, and the milling cutter 103 rotates along the side of the round table 117; The rotation axis of the seat 102 is provided with a through hole that is rotatably matched with the fixed connecting rod 118; one end of the fixed connecting rod 118 is connected with the fixed seat 119, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com