Sampling device and sampling method

A sampling device and sampling machine technology, applied in the direction of sampling devices, etc., can solve the problems of poor stability, complex structure, difficult to adapt to alloy materials, etc., and achieve the effect of smooth sampled parts, easy welding and repair, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

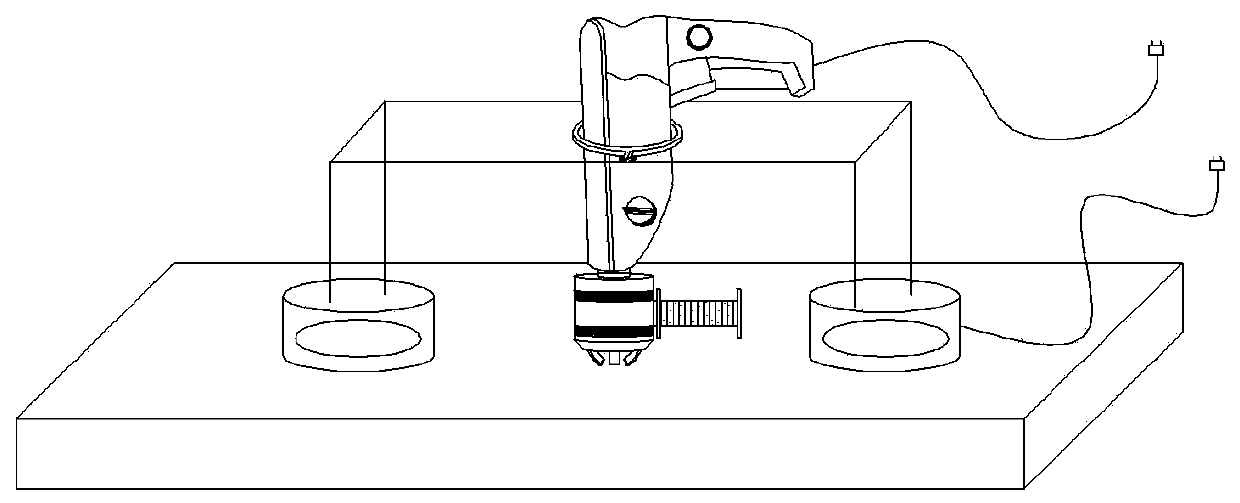

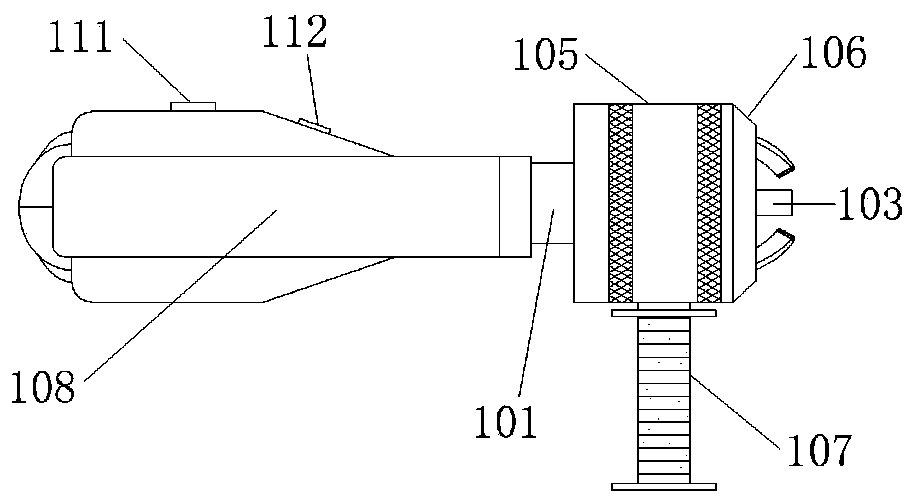

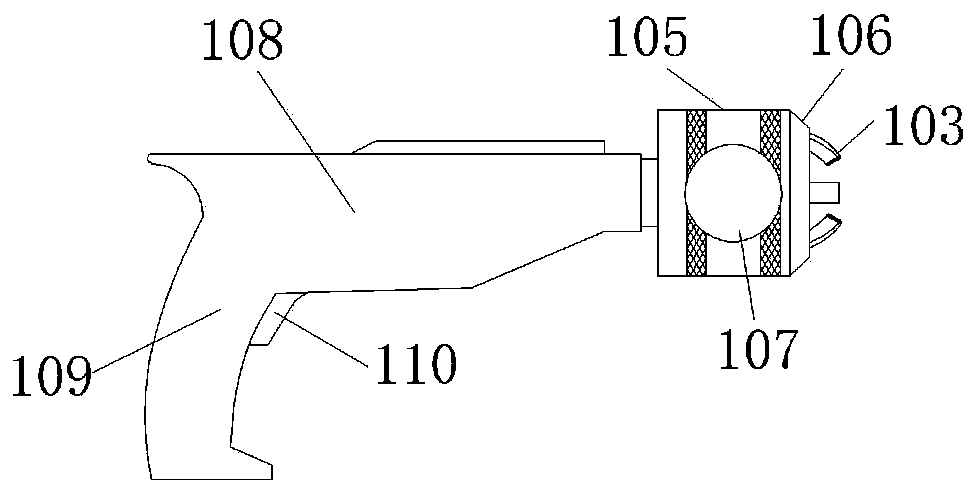

[0040] This embodiment provides a sampling device, such as Figure 1-Figure 6 As shown, it includes a sampling machine and a fixed frame; the sampling machine includes a sampling head and a rotary drive mechanism, the rotary drive mechanism is arranged on the fixed frame, and the fixed frame is provided with a connection mechanism for fixed connection with the member to be sampled.

[0041] The sampling head comprises a threaded seat, a rotating seat 102 and a milling cutter 103; the rotating seat is connected with the output shaft of the rotary drive mechanism; the rotating seat 102 is provided with a guide groove corresponding to the milling cutter 103; the milling cutter 103 is arranged on the guide groove, and One side of the axis of rotation; the end of the milling cutter 103 is provided with a blade 116, and the end is facing the axis of rotation; the end of the milling cutter 103 away from the end is the tail end, and the tail end is away from the axis of rotation; the c...

Embodiment 2

[0057] This embodiment provides a magnetic fixing frame, such as Figure 10 As shown, it includes: a bridge-shaped support and a clamping mechanism for clamping the body of the sampler; the bridge-shaped support includes a fixed frame 120 and two support seats; the two support seats are respectively arranged on two opposite sides of the fixed frame 120 end; the top of the support seat is connected to the fixed frame 120, and the bottom of the support seat is provided with a magnetic element; the clamping mechanism is connected to the fixed frame 120 and is located in the fixed frame 120.

[0058] The magnetic fixing frame based on the above structure can be fixed on metal components of various shapes through the magnetic force generated by the magnetic element installed on the support seat, thereby expanding the scope of application; at the same time, the micro-damage sampling machine is clamped Tightly fixed on the magnetic fixing frame to prevent the sampling machine from mo...

Embodiment 3

[0070] This embodiment provides another structure of the threaded seat, such as Figure 11 As shown, it includes an inverted fixed seat 119, a round platform 117 and a fixed connecting rod 118; the side of the round platform 117 forms a tapered surface, and the thread is arranged on the side of the round platform 117 to form an external thread structure; the side of the milling cutter 103 facing the rotating shaft For the inner side, the tooth pattern segment 115 is arranged on the inner side of the milling cutter 103; the round table 117 and the milling cutter 103 are located on the same side of the rotating seat 102, and the round table 117 is located on the inner side of the milling cutter 103, and the milling cutter 103 rotates along the side of the round table 117; The rotation axis of the seat 102 is provided with a through hole that is rotatably matched with the fixed connecting rod 118; one end of the fixed connecting rod 118 is connected with the fixed seat 119, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com